A multifunctional stirring device

A stirring device and multi-functional technology, which can be used in mixers with rotary stirring devices, mixer accessories, transportation and packaging, etc., can solve the problem that the stirring blades cannot be flexibly adjusted and set.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

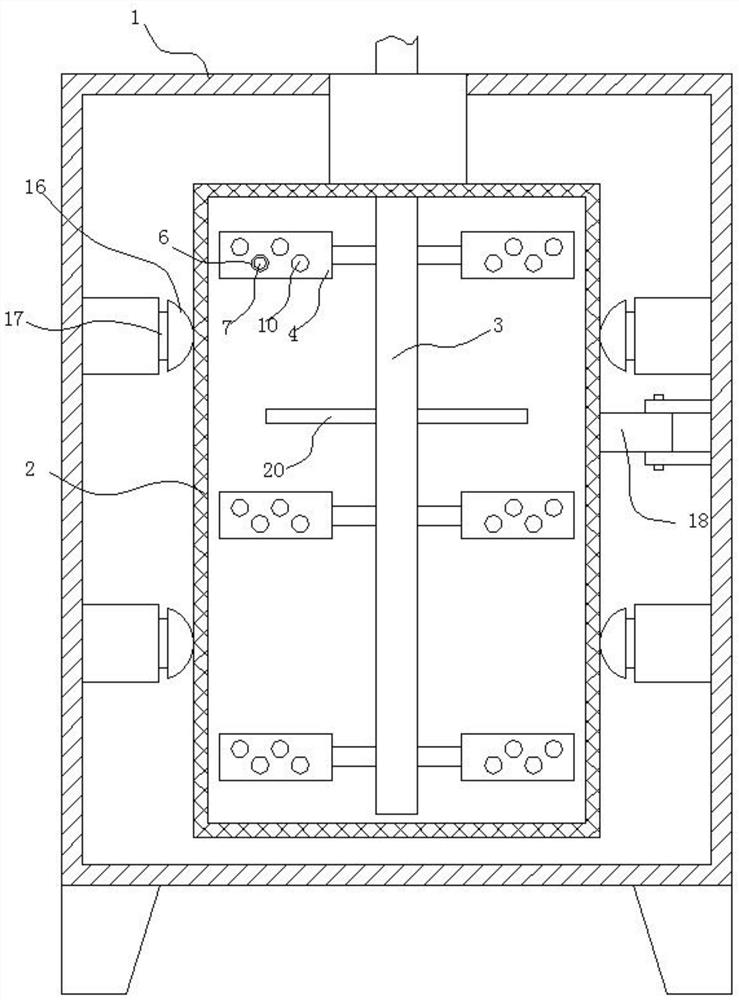

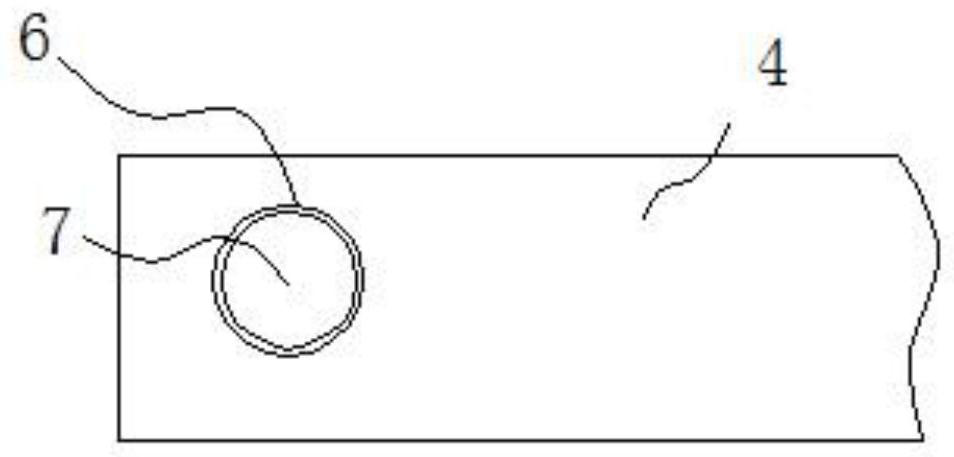

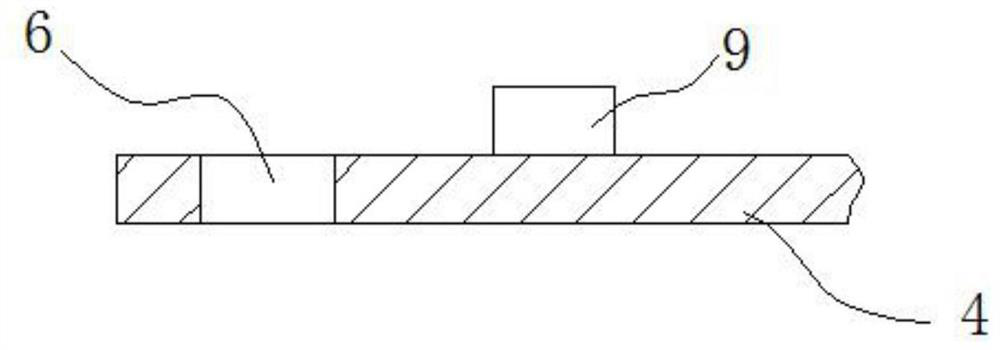

[0029] Such as Figure 1 to Figure 4 As shown, a multifunctional stirring device includes a housing 1, an elastic kettle body 2 is installed in the housing 1, and a rotating shaft 3 extending up and down is installed in the rotating shaft 2, and the rotating shaft 3 is installed symmetrically. There are stirring blades, the stirring blades include a first stirring blade 4 and a second stirring blade 5 bonded together with the first stirring blade 4, a plurality of first through holes 6 are arranged on the first stirring blade 4, The second agitating blade 5 is provided with a second boss 7 which is plugged in the first through hole 6 in cooperation with the first through hole 6, and the second agitating blade 5 is provided with a plurality of first Two through holes 8, the first agitating blade 4 is provided with a first boss 9 cooperating with the second through hole 8 plugged in the second through hole 8, the first agitating blade 4 and An opening and closing control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com