An automatic pouring reactor

A technology of a reaction kettle and a reaction kettle body, which is applied in the field of automatic dumping type reaction kettles, can solve the problems of poor flexibility, the discharge port cannot be set too large, and it takes a long time to discharge materials, so as to achieve the effect of sufficient reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

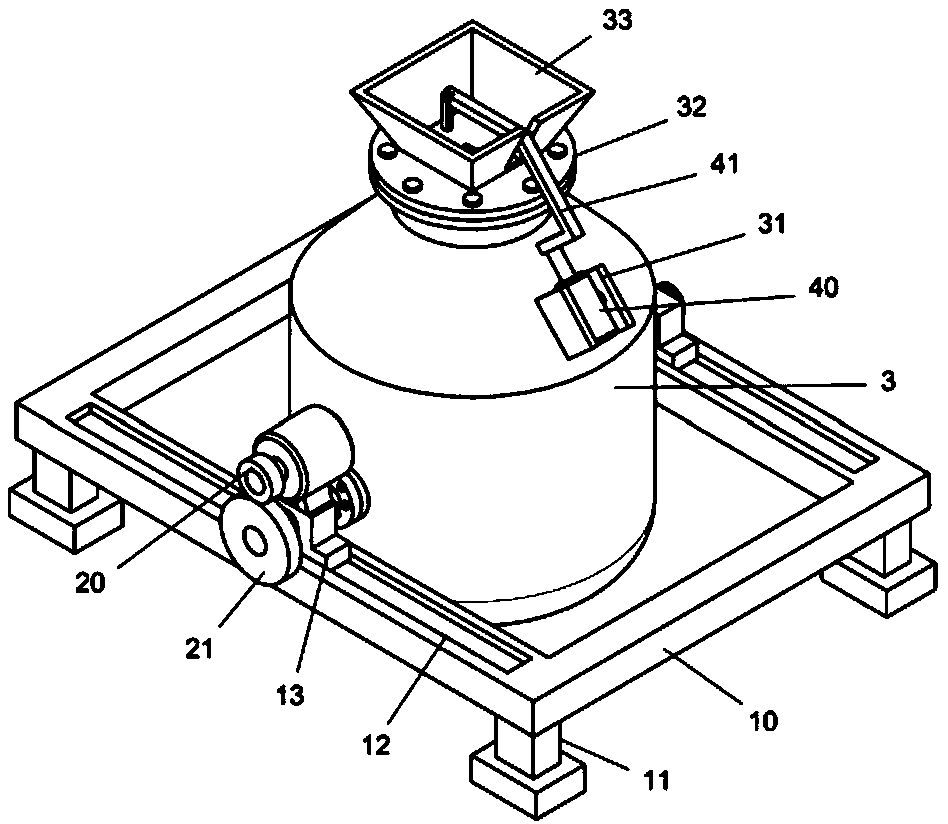

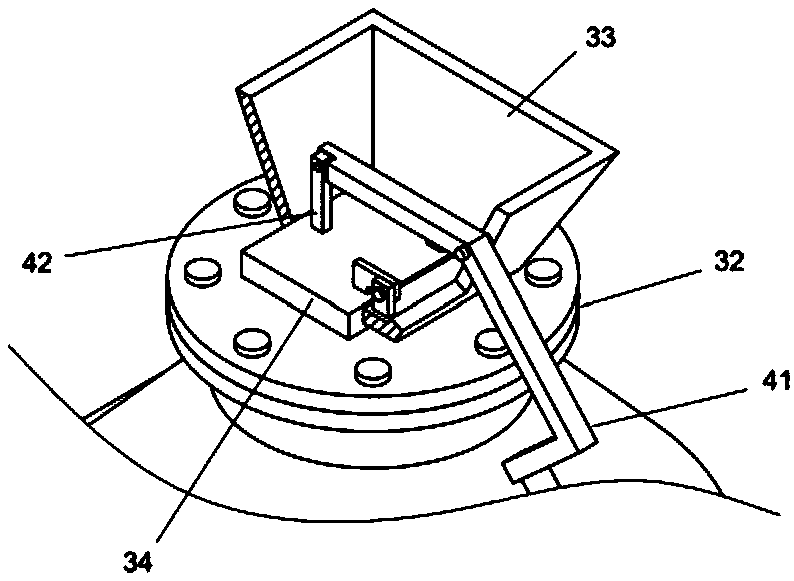

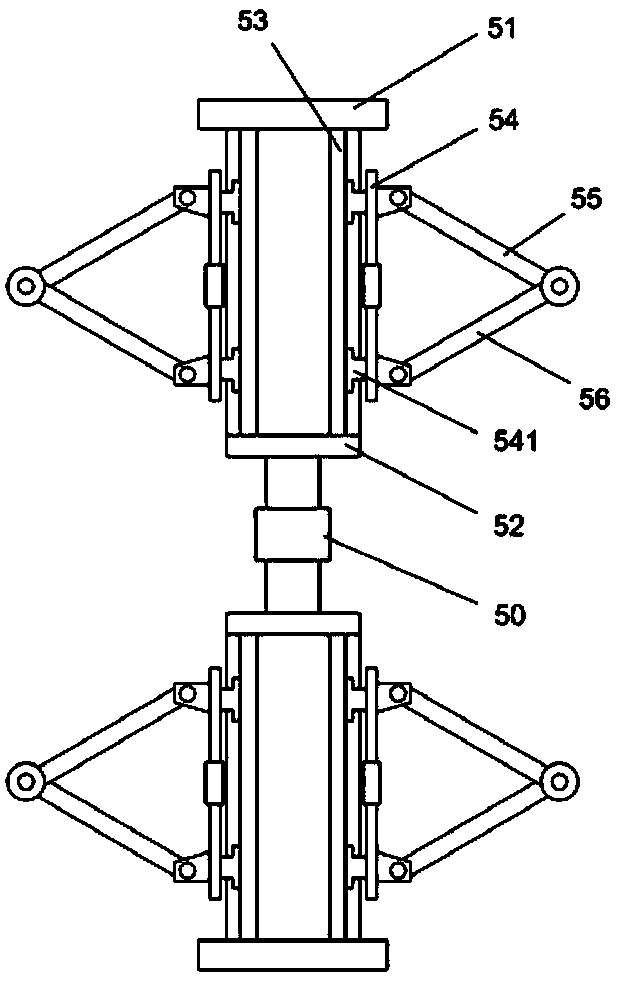

[0017] Such as Figure 1-3 Shown, a kind of automatic pouring type reactor, it comprises frame 10 and reactor body 3, frame 10 bottom four corners are provided with lifting adjustment mechanism 11, and the bottom of lifting adjustment mechanism 11 is fixed with buffer feet; frame 10 is The square frame structure includes two oppositely arranged beams and oppositely arranged longitudinal beams. Both longitudinal beams are provided with chute 12, the side of chute 12 is provided with a linear rack, and sliding block 13 is arranged in chute 12. The two sides of the slider 13 are provided with traveling gears, and the traveling gears and racks are meshed and connected; the upper part of the slider is provided with a bearing seat, and a sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com