A roller tile used for bonding oil channel stays

A technology of oil passage and bonding, which is applied in the field of roller tiles bonded by oil passage stays, can solve the problems of slow speed and achieve mechanization and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

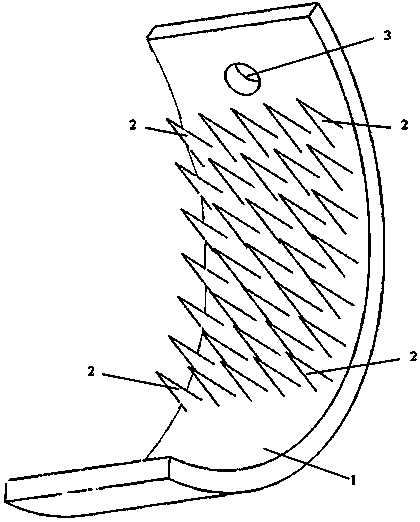

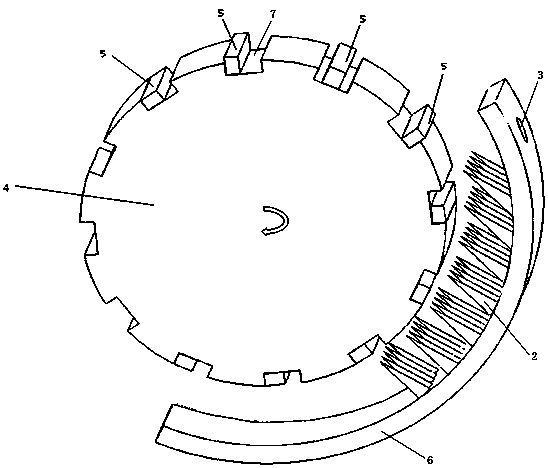

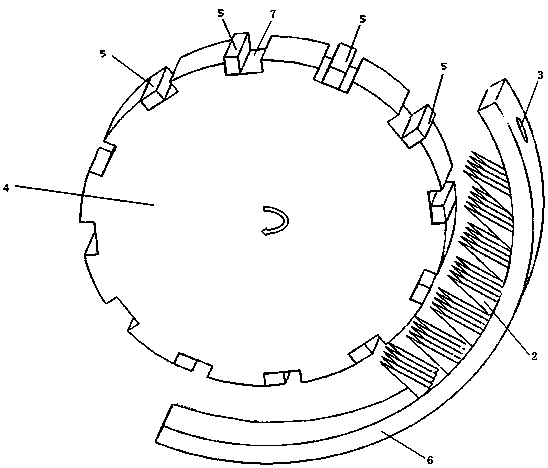

[0029] When the roller tile 1 is assembled with the roller 4, the distance from the tile body 6 to the central axis of the roller 4 decreases sequentially from top to bottom, and the turning device 2 is conical, and from top to bottom, the conical tip reaches the outer surface of the roller 4 The distance also decreases sequentially. Oil passage stays are 6mm wide and 5mm thick. The maximum distance from the conical tip to the outer surface of the roller 4 is 1 mm, and the minimum distance is 0 mm. Roller grooves 7 parallel to the central axis are evenly distributed on the outer surface of the roller 4, and oil passage stays 5 are housed in the roller grooves 7. On the side where the roller 4 rotates downward, the oil passage stay 5 whose thick side is radially consistent with the roller 4 does not touch the convex point and passes through smoothly, and the oil passage stay whose thick side is not consistent with the radial direction of the roller 4 The part of the bar 5 pro...

Embodiment 2

[0031] When the roller shoe 1 is assembled with the roller wheel 4, the distance from the tile body 6 to the center axis of the roller wheel 4 decreases sequentially from top to bottom, and the turning device 2 is barb-shaped, with the top point upward; The distance of the outer surface of the roller 4 also decreases successively. The oil passage stay is 5.7mm wide and 5.2mm thick. The maximum distance from the barbed top to the outer surface of the roller 4 is 0.5 mm, and the minimum distance is 0 mm. Roller grooves 7 parallel to the central axis are evenly distributed on the outer surface of the roller 4, and oil passage stays 5 are housed in the roller grooves 7. On the side where the roller 4 rotates downward, the oil passage stay 5 whose thick side is radially consistent with the roller 4 does not touch the convex point and passes through smoothly, and the oil passage stay whose thick side is not consistent with the radial direction of the roller 4 The part of the bar 5...

Embodiment 3

[0033]When the roller shoe 1 is assembled with the roller 4, the distance from the tile body 6 to the central axis of the roller 4 decreases sequentially from top to bottom, and the turning device 2 is hemispherical; from top to bottom, the hemispherical top reaches the outer surface of the roller 4 The distance also decreases sequentially. Oil channel stays are 6.2mm wide and 4.6mm thick. The maximum distance from the barbed top to the outer surface of the roller 4 is 1.3 mm, and the minimum distance is 0 mm. Roller grooves 7 parallel to the central axis are evenly distributed on the outer surface of the roller 4, and oil passage stays 5 are housed in the roller grooves 7. On the side where the roller 4 rotates downward, the oil passage stay 5 whose thick side is radially consistent with the roller 4 does not touch the convex point and passes through smoothly, and the oil passage stay whose thick side is not consistent with the radial direction of the roller 4 The part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com