Device and method for aligning and splicing oil duct struts

An oil channel and bonding technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as slow speed, achieve the effect of mechanization and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

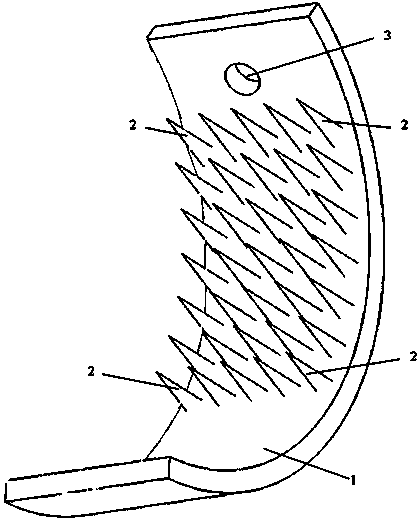

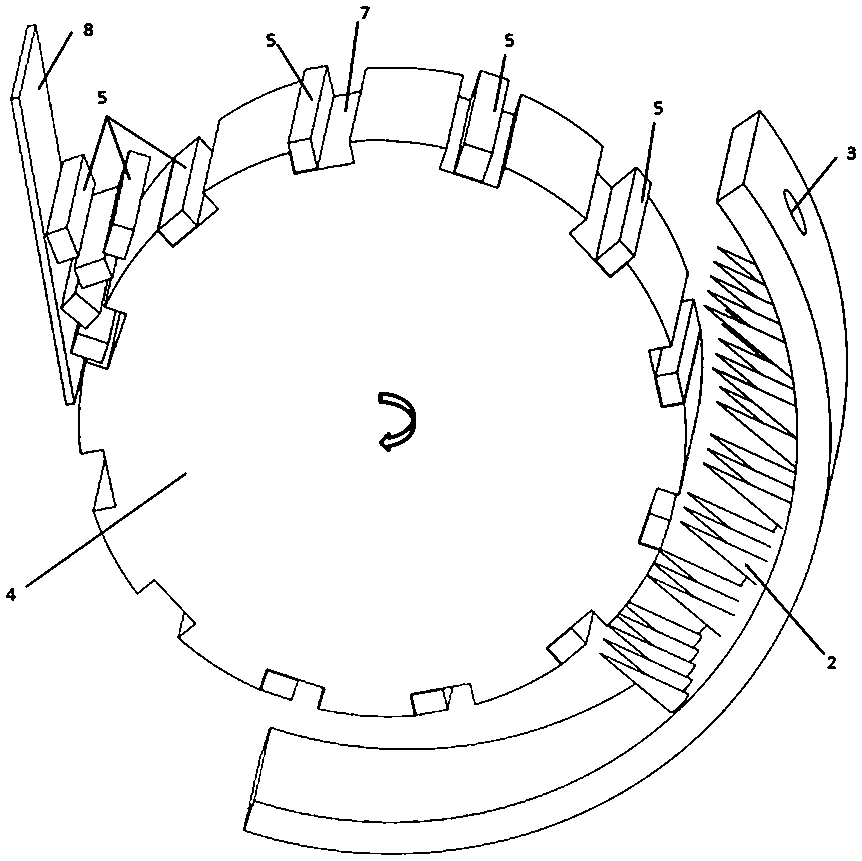

[0039] When the roller tile 1 is assembled with the roller 4, the distance from the tile body 6 to the central axis of the roller 4 decreases sequentially from top to bottom, and the turning device 2 is conical, and from top to bottom, the conical tip reaches the outer surface of the roller 4 The distance also decreases sequentially. Oil passage stays are 6mm wide and 5mm thick. The maximum distance from the conical tip to the outer surface of the roller 4 is 1 mm, and the minimum distance is 0 mm. The roller grooves 7 parallel to the central axis are uniformly distributed on the outer surface of the roller 4 . An inverted triangular area is formed between the feeding plate 8 and the roller 4, and the roller 4 rotates upwards through this inverted triangular area, and an oil channel stay 5 is installed in each roller groove 7. On the side where the roller 4 rotates downward, the oil passage stay 5 whose thick side is radially consistent with the roller 4 does not touch the c...

Embodiment 2

[0041] When the roller shoe 1 is assembled with the roller wheel 4, the distance from the tile body 6 to the center axis of the roller wheel 4 decreases sequentially from top to bottom, and the turning device 2 is barb-shaped, with the top point upward; The distance of the outer surface of the roller 4 also decreases successively. The oil passage stay is 5.7mm wide and 5.2mm thick. The maximum distance from the barbed top to the outer surface of the roller 4 is 0.5 mm, and the minimum distance is 0 mm. The roller grooves 7 parallel to the central axis are uniformly distributed on the outer surface of the roller 4 . An inverted triangular area is formed between the feeding plate 8 and the rollers 4, and the rollers rotate upwards through this inverted triangular area, and oil passage stays 5 are installed in each roller groove 7. On the side where the roller 4 rotates downward, the oil passage stay 5 whose thick side is radially consistent with the roller 4 does not touch the...

Embodiment 3

[0043] When the roller shoe 1 is assembled with the roller 4, the distance from the tile body 6 to the central axis of the roller 4 decreases sequentially from top to bottom, and the turning device 2 is hemispherical; from top to bottom, the hemispherical top reaches the outer surface of the roller 4 The distance also decreases sequentially. Oil channel stays are 6.2mm wide and 4.6mm thick. The maximum distance from the barbed top to the outer surface of the roller 4 is 1.3 mm, and the minimum distance is 0 mm. The roller grooves 7 parallel to the central axis are uniformly distributed on the outer surface of the roller 4 . An inverted triangular area is formed between the feeding plate 8 and the rollers 4, and the rollers rotate upwards through this inverted triangular area, and oil passage stays 5 are installed in each roller groove 7. On the side where the roller 4 rotates downward, the oil passage stay 5 whose thick side is radially consistent with the roller 4 does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com