Device and method for aligning and splicing oil duct struts

An oil channel and bonding technology, used in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as slow speed, and achieve the effect of improving production efficiency and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

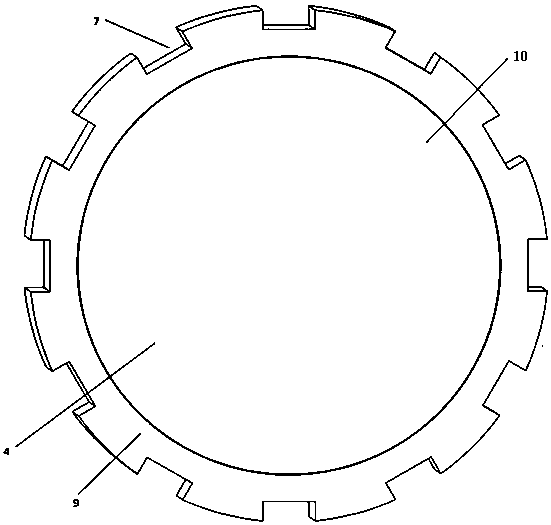

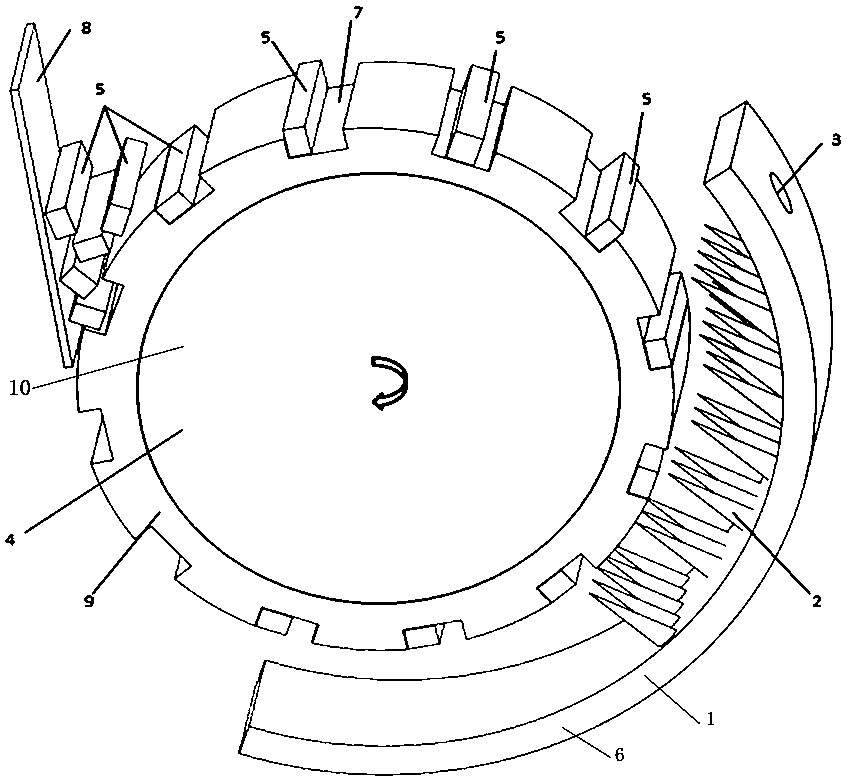

[0045] Select the roller sleeve 9 consistent with the technical requirements, and install it on the roller body 10. When the roller tile 1 is assembled with the roller 4, the distance from the tile body 6 to the central axis of the roller body 10 decreases sequentially from top to bottom, and the turning device 2 is conical, and from top to bottom, the conical top reaches the roller body 10 The distance on the outer side also decreases successively. Oil passage stays are 6mm wide and 5mm thick. The maximum distance from the conical top to the outer surface of the roller sleeve 9 is 1 mm, and the minimum distance is 0 mm. The roller grooves 7 parallel to the central axis are evenly distributed on the outer surface of the roller sleeve 9 . An inverted triangular area is formed between the feeding plate 8 and the roller sleeve 9, and the roller sleeve 9 rotates upwards through this inverted triangular area, and each roller groove 7 is filled with an oil channel stay 5. On the ...

Embodiment 2

[0047] Select the roller sleeve 9 consistent with the technical requirements, and install it on the roller body 10. When the roller tile 1 is assembled with the roller body 10, the distance from the tile body 6 to the central axis of the roller body 10 decreases sequentially from top to bottom, and the turning device 2 is barb-shaped with the top point upward; from top to bottom, barb-shaped The distance from the top to the outer surface of the roller sleeve 9 also decreases successively. The oil passage stay is 5.7mm wide and 5.2mm thick. The maximum distance from the barbed top to the outer surface of the roller sleeve 9 is 0.5mm, and the minimum distance is 0mm. The roller grooves 7 parallel to the central axis are evenly distributed on the outer surface of the roller sleeve 9 . An inverted triangular area is formed between the feeding plate 8 and the roller sleeve 9, and the rollers 4 rotate upwards through this inverted triangular area, and oil passage stays 5 are insta...

Embodiment 3

[0049] Select the roller sleeve 9 consistent with the technical requirements, and install it on the roller body 10. When the roller tile 1 is assembled with the roller body 10, the distance from the tile body 6 to the central axis of the roller body 10 decreases sequentially from top to bottom, and the turning device 2 is hemispherical; from top to bottom, the hemispherical top reaches the roller sleeve 9 The distance on the outer side also decreases successively. Oil channel stays are 6.2mm wide and 4.6mm thick. The maximum distance from the barbed top to the outer surface of the roller sleeve 9 is 1.3 mm, and the minimum distance is 0 mm. The roller grooves 7 parallel to the central axis are evenly distributed on the outer surface of the roller sleeve 9 . An inverted triangular area is formed between the feeding plate 8 and the rollers 4, and the rollers rotate upwards through this inverted triangular area, and oil passage stays 5 are installed in each roller groove 7. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com