Demoulding tool for wedge-shaped part of aircraft wingtip

A technology for wedges and wingtips, which is applied in the demoulding tool and field of demoulding tools for aircraft wingtip wedges. It can solve the problems of parts rejection, damage, parts scratches, etc., and achieve the effect of uniform traction load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

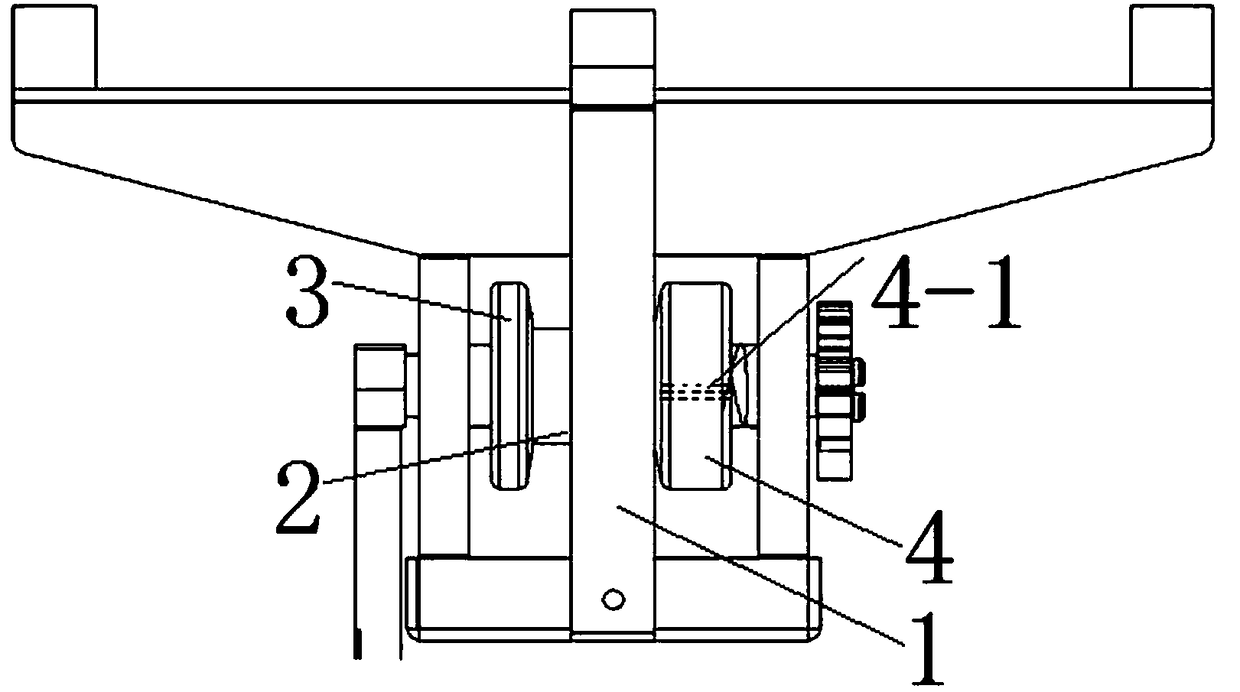

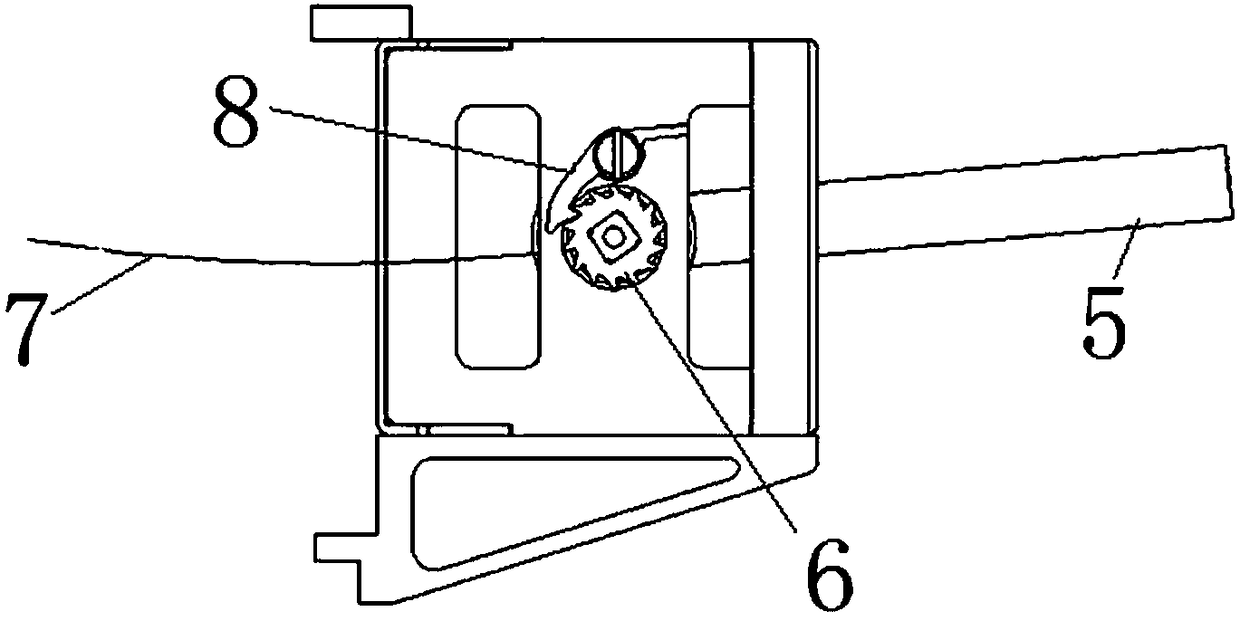

[0015] Such as figure 1 and figure 2 As shown, a demoulding workpiece used for aircraft wingtip wedges, a transmission mechanism is connected through the frame 1, a ratchet wrench 5 is connected to one end of the transmission mechanism, and a locking mechanism is provided at the other end, and the locking mechanism is located at the bottom of the frame 1. outer wall.

[0016] The transmission mechanism is as follows: the concentric shaft 2 runs through the two opposite side walls of the frame 1, the outer circumference of the concentric shaft 2 is covered with the rim I 3 and the rim II4, and one end of the traction rope 7 is fixed on the concentric shaft 2 outside the rim II4 , the other end passes through the positioning hole 4-1 and winds around the outer circumference of the concentric shaft 2 between the rim I3 and the rim II4.

[0017] The locking mechanism is as follows: a locking hook 8 is connected to the side wall of the frame 1, a runner 6 is set on the outer cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com