Double-coil bistable-state electromagnetic mechanism provided with armature with sealing conical surface

A technology of electromagnetic mechanism and sealing cone surface, which is applied in the direction of mechanical equipment, engine components, valve details, etc., can solve the problems of monostable state maintenance, no energy saving, high power consumption, etc., and achieve permanent magnet circuit maintenance, output force and retention force The effect of increasing the initial output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

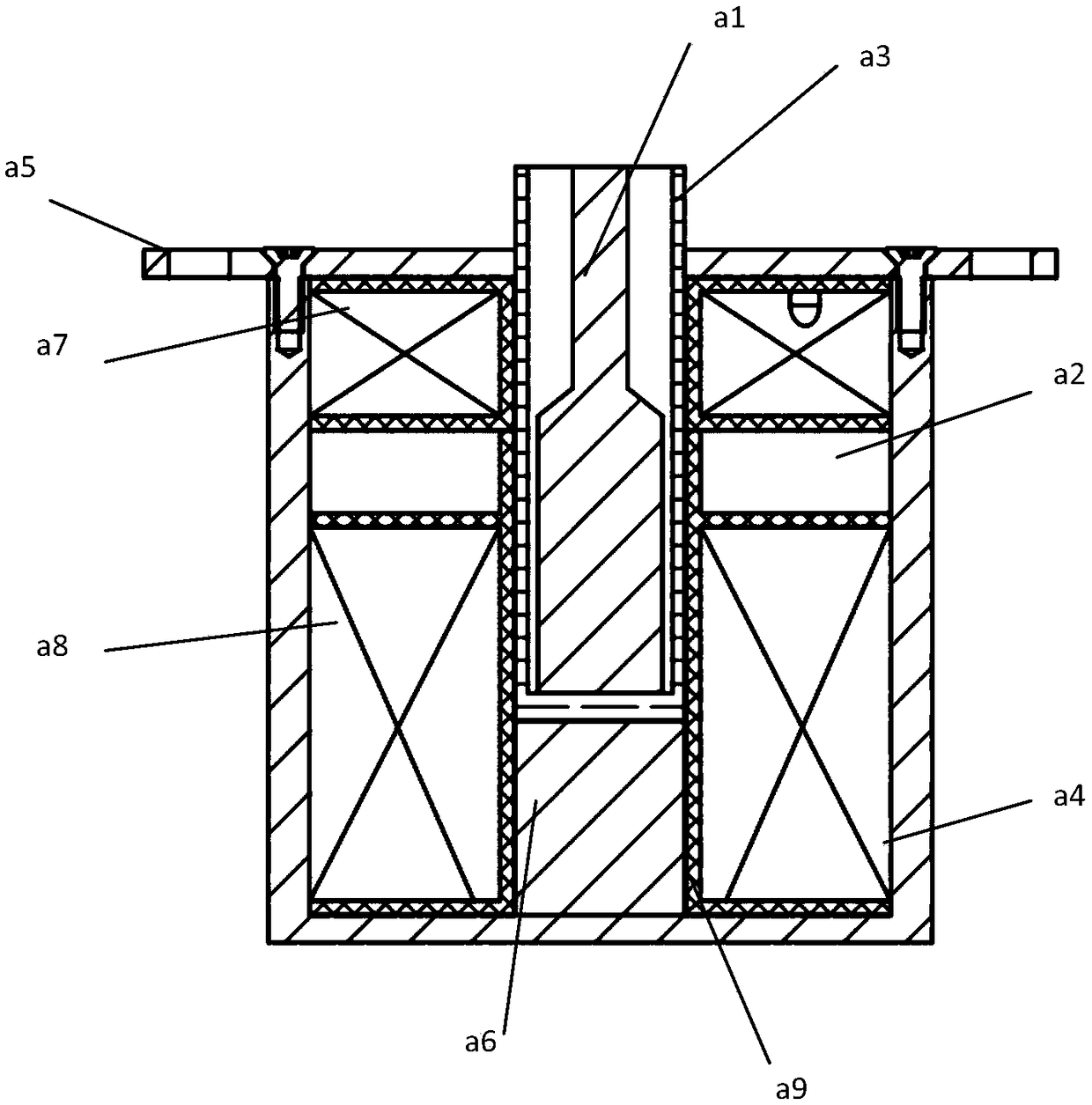

[0032] In a specific embodiment, the electromagnetic mechanism provided by the present invention can be realized in the following structural manner.

[0033] The double-coil bistable electromagnetic mechanism of the sealed conical armature provided by the invention, which can be applied to many fields such as valve control, has large stroke, high holding force, large output force and low power consumption. The design of the mechanism is suitable for application in valve control systems For example, in air conditioners, oil pipelines, heating pipelines and other equipment, it has the characteristics of large stroke, large output force, positive and negative pulse drive, bistable permanent magnet circuit maintenance, simple pipeline, low cost, and small size. After the electromagnetic system, the force change can be quickly adjusted by replacing the permanent magnet (within the magnetic saturation range), and multiple adjustments of the permanent magnet and part size can also be ...

Embodiment 2

[0040] In a specific embodiment, the specific working process of the electromagnetic mechanism provided by the present invention can be carried out in the following manner:

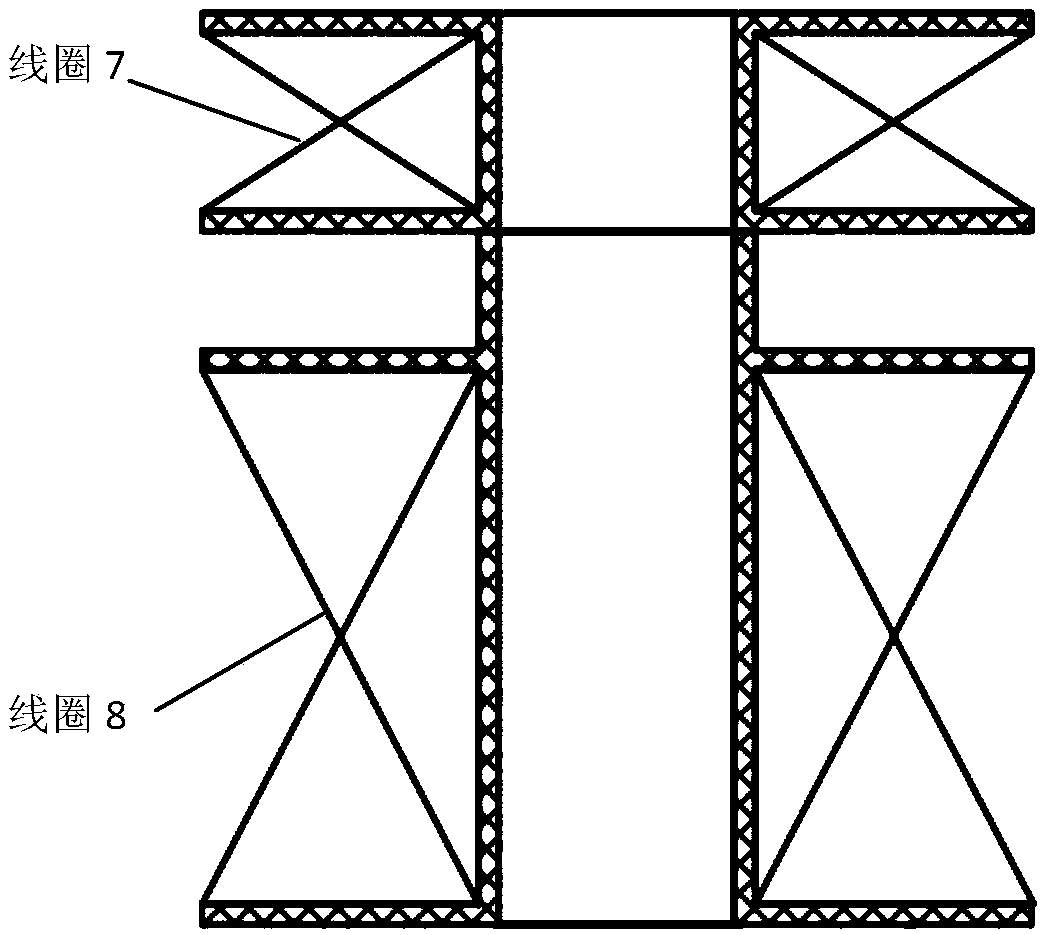

[0041] like Figure 4 , the lower end of the armature a1 is closed and is in the release position. The lower end surface of the armature a1 and the static iron core a6 form a working air gap 1; the coil one a7 and the coil two a8 are wound on the bobbin a9, the tapered surface of the armature a1 and the upper yoke a5 A working air gap 2 is formed on the upper pole surface. The inner surface of the permanent magnet a2 and the outer surface of the armature a1 form a non-working air gap 3. At this time, the magnetic flux of the permanent magnet magnetic circuit without current applied to the coil 1 a7 and coil 2 a8 has two closed magnetic circuits, and the magnetic circuit 1: the permanent magnet N pole - non-working air gap 3 - lower half of armature a1 - working air gap 1 - static iron core a6 - bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com