Improved concrete batch plant

A mixing equipment and concrete technology, which is applied in the direction of clay preparation equipment, cement mixing equipment, liquid ingredient supply equipment, etc., can solve the problems of low mixing effect, inability to add additives, poor mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

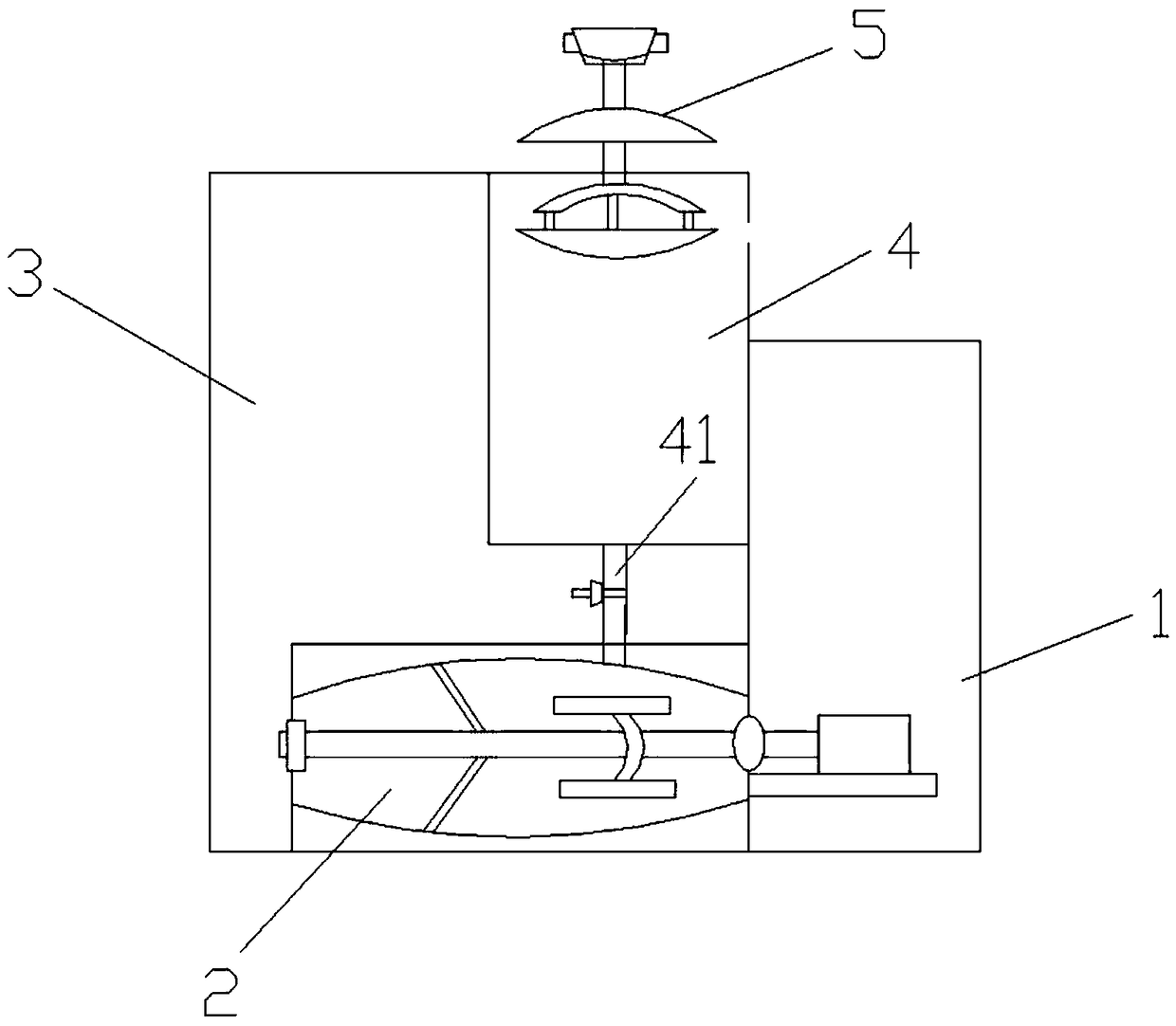

[0019] combine Figure 1 to Figure 3 The concrete mixing device of the present invention will be described in detail.

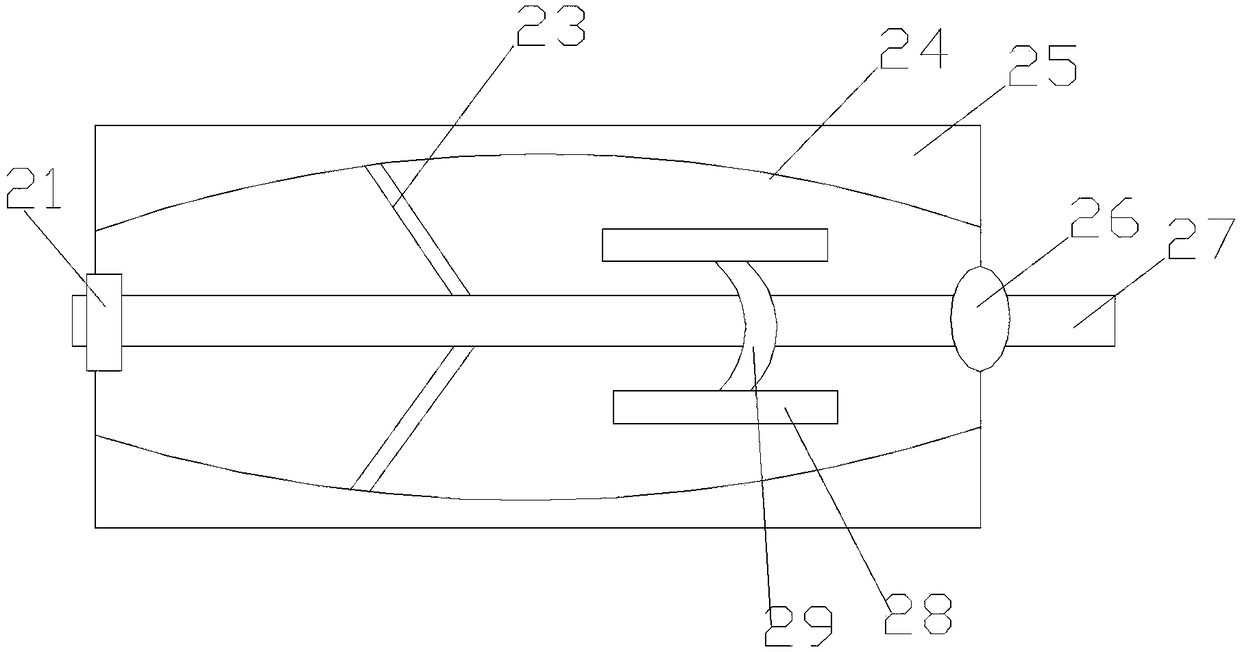

[0020] An improved concrete mixing equipment according to the present invention comprises a driving box 1, a mixing box 3 arranged on the side wall of the driving box 1, a mixing unit 2 arranged at the bottom of the mixing box 3, The additive unit 5 snapped on the upper part of the mixing box 3;

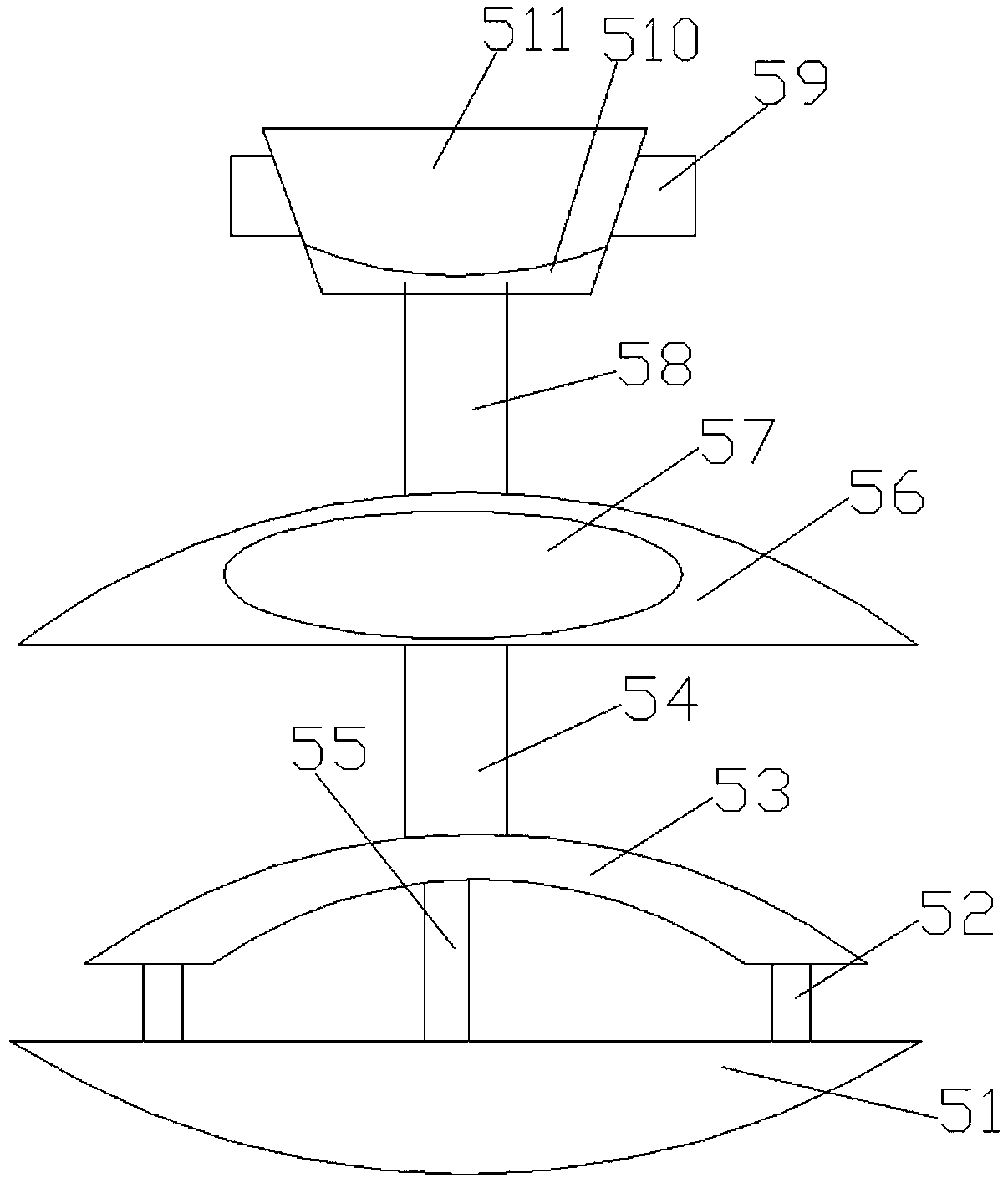

[0021] The additive unit 5 includes a spray head 51, a circular tubular first delivery pipe 52 that is screwed on the upper side of the spray head 51 and communicated with the inner cavity of the spray head 51, and is screwed on the middle of the spray head 51. The circular tube-shaped fourth conveying pipe 55, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap