A kind of molybdenum oxide nanopowder and its preparation method and application

A technology of nano-powder and molybdenum oxide, which is applied in the field of inorganic nano-materials, can solve the problems of low light adjustment efficiency and inability to freely control the light adjustment range of molybdenum oxide, so as to increase electron concentration, improve light adjustment efficiency, and improve light adjustment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Figure 4 A schematic flow chart showing a method for preparing molybdenum oxide nanopowder according to an embodiment of the present invention. see Figure 4 , the method may include the following steps:

[0051] Step S510: adding a molybdenum-containing solution to the acid solution to adjust the pH value to the pH threshold value to obtain a precursor solution;

[0052] Step S520: Transfer the precursor solution to a hydrothermal reaction device, and keep it warm at the target temperature for a preset time to obtain a molybdenum oxide dispersion;

[0053] Step S530: post-processing the molybdenum oxide dispersion to obtain molybdenum oxide nanopowder.

[0054] In a specific embodiment, in step S510, the acid solution may include at least one of hydrochloric acid, sulfuric acid, nitric acid, oxalic acid, citric acid, acetic acid and the like. The concentration of the acid solution is not particularly limited, and a concentration commonly used in the art can be use...

Embodiment 1

[0064] Step A) Weigh 7.8g of sodium molybdate, dissolve it in 50ml of water, and stir until completely dissolved. Add 10ml of saturated oxalic acid solution, then slowly add saturated oxalic acid dropwise while stirring until the pH value is 1, and stir for half an hour until the hexavalent molybdenum precursor solution is obtained;

[0065] Step B) Take 50ml of the precursor solution and add it to the reaction kettle, transfer it to a hydrothermal furnace, set the temperature at 120°C, and keep it warm for 30h;

[0066] Step C) After the hydrothermal reaction is over, let it cool naturally, turn on the hydrothermal furnace, and carry out the reaction mother liquor containing the nano-powder of anoxic molybdenum oxide (hereinafter also referred to as "anoxic molybdenum oxide nano-powder") for several times. Wash and filter until the acid substances on the surface of the powder are washed clean, transfer to a drying oven, and dry at 80°C for 8 hours.

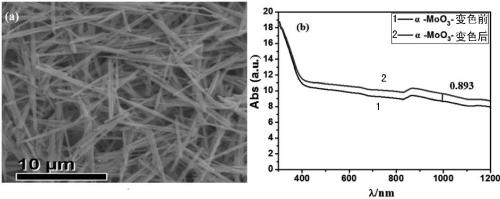

[0067] The properties of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com