Defoaming device and defoaming method

A defoaming device and defoaming technology, applied in the direction of chemical instruments and methods, separation methods, maintenance and safety accessories, etc., can solve the problems of cutting fluid leakage, cutting fluid reduction, and deterioration of the working environment, so as to overcome the liquid level rise Fluctuation, liquid level vibration suppression, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Specific embodiments to which the present invention is applied are described below with reference to the drawings.

[0079] (Embodiment of the present invention)

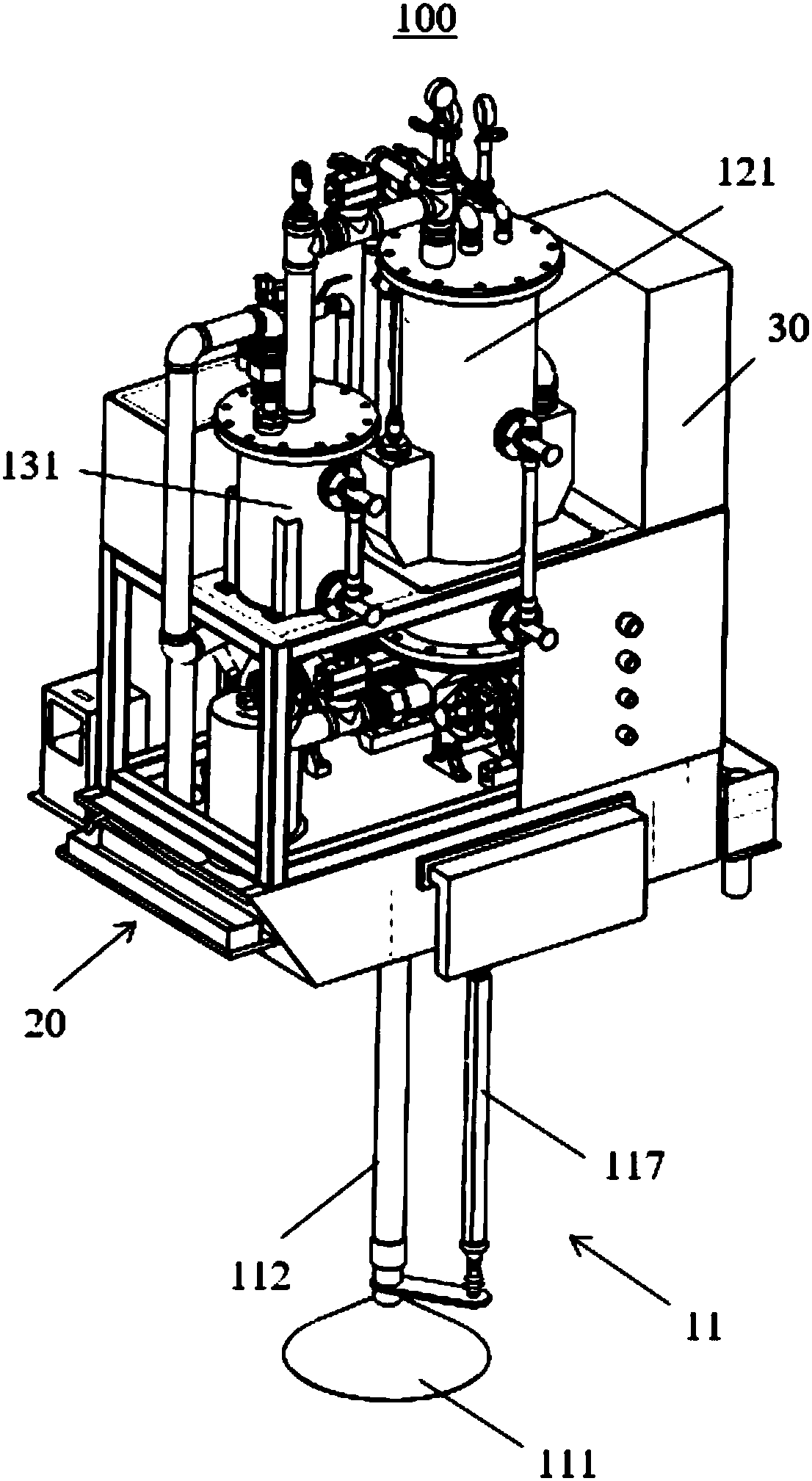

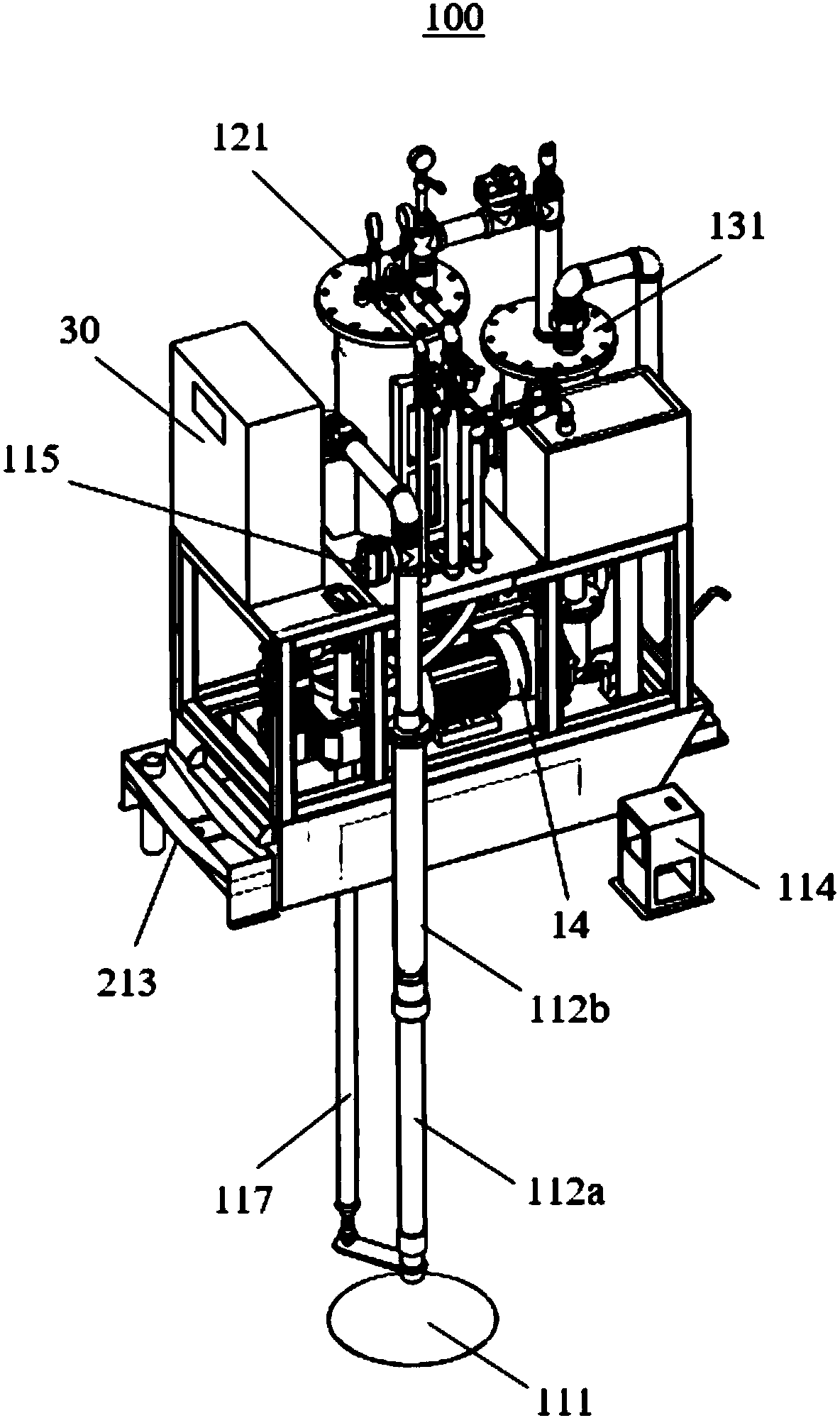

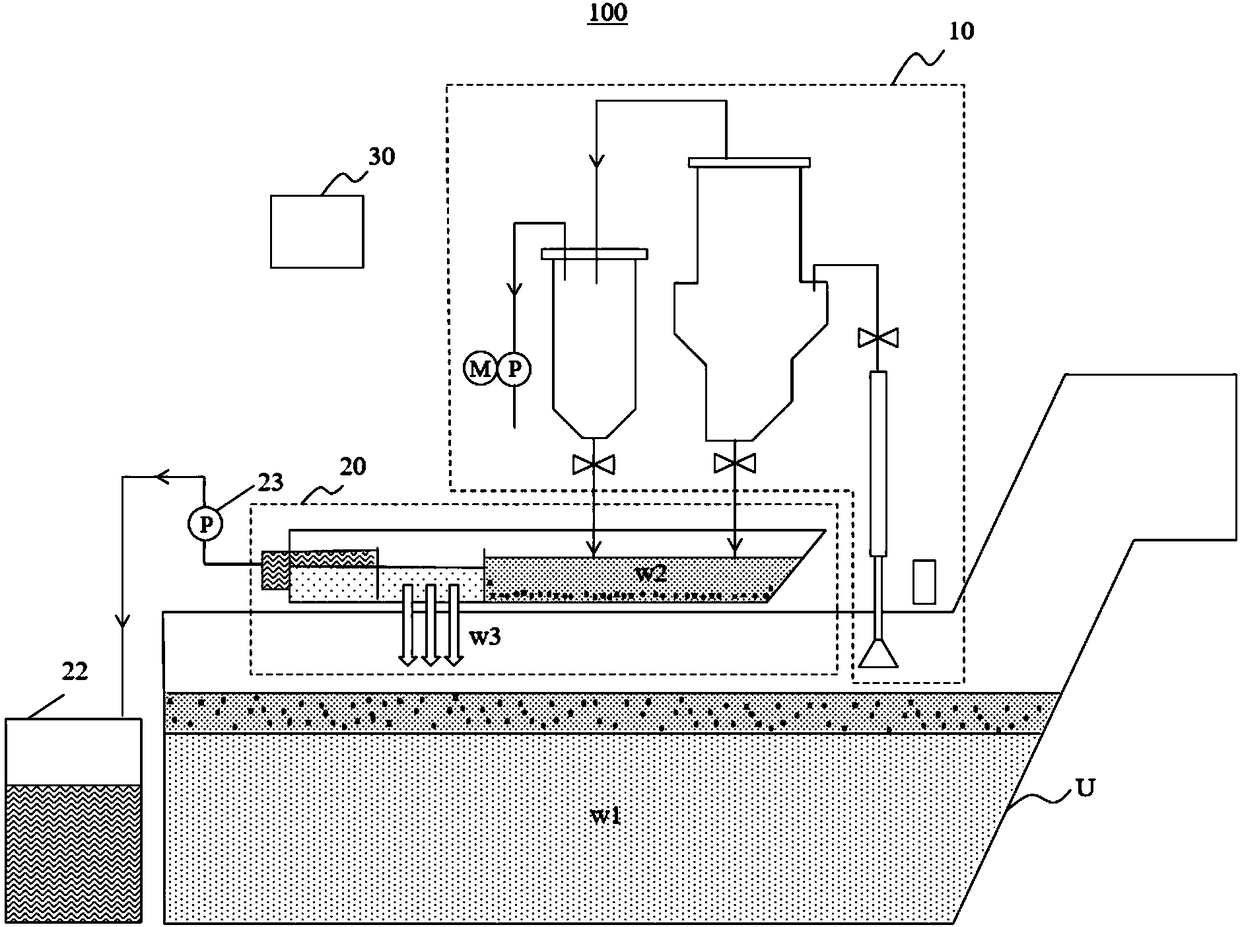

[0080] figure 1 is a three-dimensional view showing the defoaming device according to the embodiment of the present invention figure 1 , figure 2 is a three-dimensional view showing the defoaming device of the above-mentioned embodiment figure 2 , image 3 It is a configuration diagram showing the arrangement of the defoaming device of the above-mentioned embodiment.

[0081] The defoaming device 100 according to the embodiment of the present invention can be installed in a chip removal device that filters cutting fluid discharged from lathes, milling machines, etc. A large number of bubbles, oil or small chips are eliminated, and the mixed oil or small chips are separated from the cutting fluid w1, and the cutting fluid w3 from which the oil has been removed is sent back to the storage tank U of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com