Anti-glare plate with light absorbing layers

An absorbing layer and anti-glare technology, which is applied to optical elements used to change the spectral characteristics of emitted light, semiconductor devices of light-emitting elements, light sources, etc., can solve the problems of large UGR value and inability to effectively reduce the UGR value of large-angle light , to achieve the effect of reducing the UGR value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

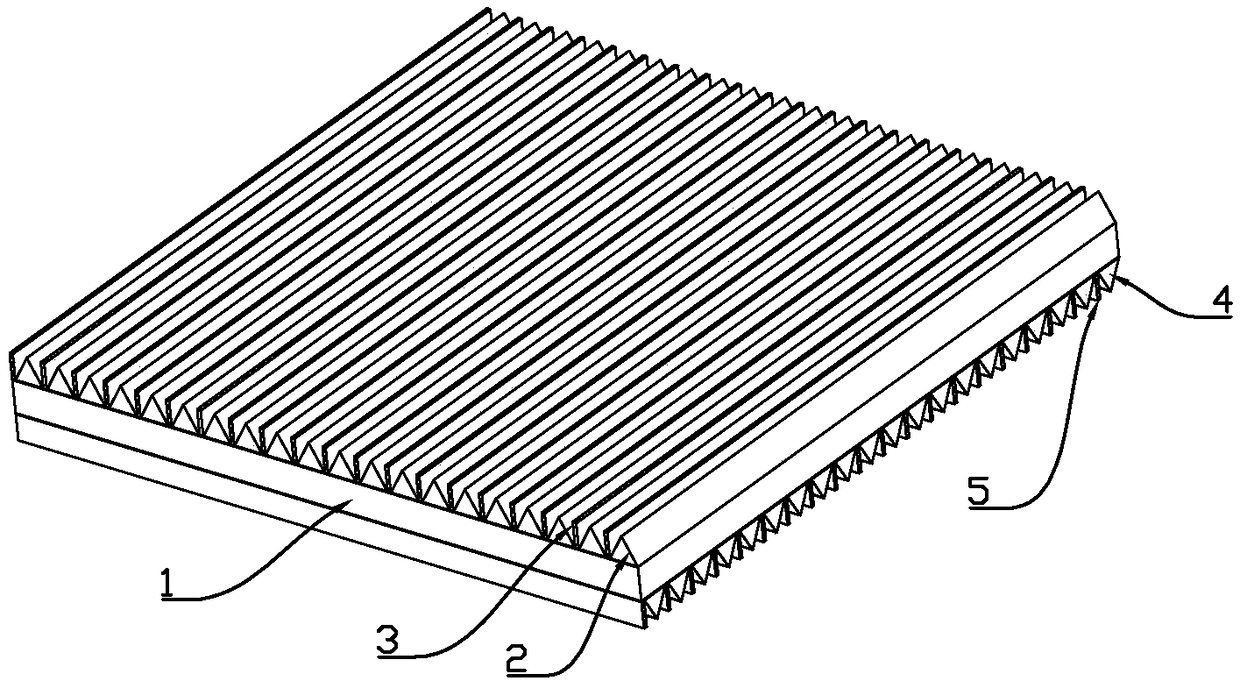

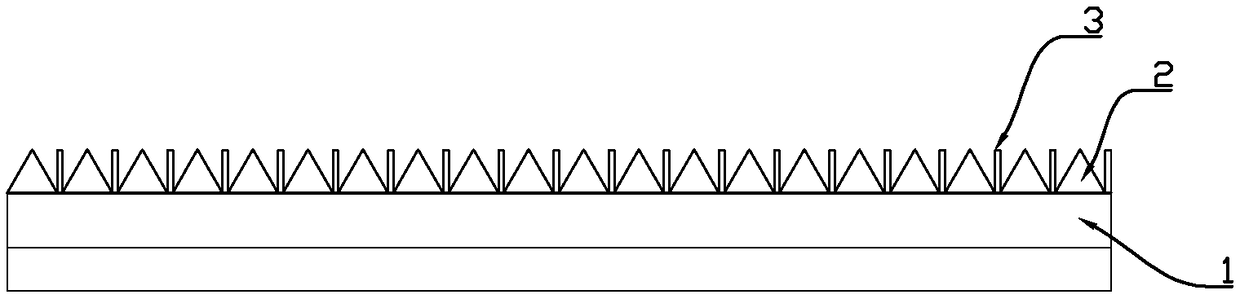

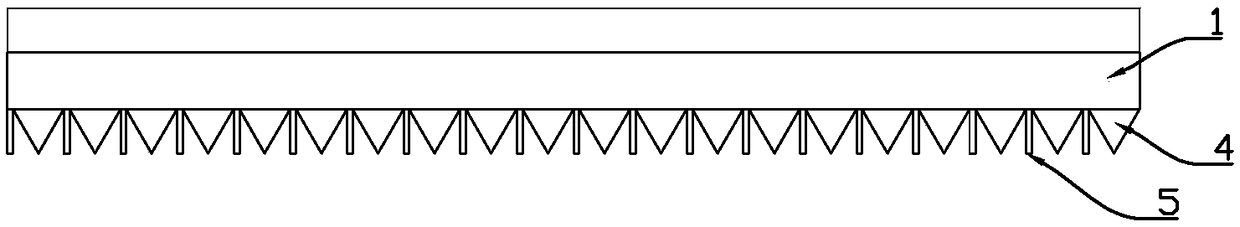

[0022] combine Figure 1 to Figure 3 , to describe this embodiment in detail. An anti-glare plate with a light-absorbing layer involved in this embodiment includes a light-transmitting layer and a first UGR reducing layer and a first absorbing layer located on one side of the light-transmitting layer; the first UGR reducing layer and the first absorbing layer Alternate settings. The first UGR lowering layer consists of triangular edges arranged in parallel. The first absorbent layer consists of partitions arranged in parallel. The triangular ribs in the first UGR reducing layer are arranged in parallel with the partitions in the first absorbing layer. The cross section of the triangular rib is triangular, and the cross section of the partition is rectangular. In this embodiment, the cross section of the triangular ridge is a regular angle. In this embodiment, the triangular edge and the partition have a common side.

[0023] Preferably, the other side of the light-transm...

Embodiment 2

[0030] combine Figure 4 to Figure 6 , to describe this embodiment in detail. The difference between the anti-glare plate with the light absorbing layer in this embodiment and the first embodiment is that the length of the triangular edge is in the range of 0.5-2 mm, which is 2 mm in this embodiment. The thickness of the light-transmitting layer can be selected in the range of 0.5-2mm, and 1mm is selected in this embodiment.

[0031] In the present invention, one A° is selected, and the half of the height of the separator and the height of the triangular edge can be calculated by substituting it, which is 1mm. The width of the separator in this embodiment is 0.4 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com