Optical element and lighting device

An optical element and lighting device technology, applied in the field of optical elements, can solve the problems of difficulty in controlling the light distribution shape and glare index of large-angle panel lamps, and it is difficult to realize the lighting effect of the batwing light distribution curve, etc. The effect of uniform surface illumination and low UGR value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the figures.

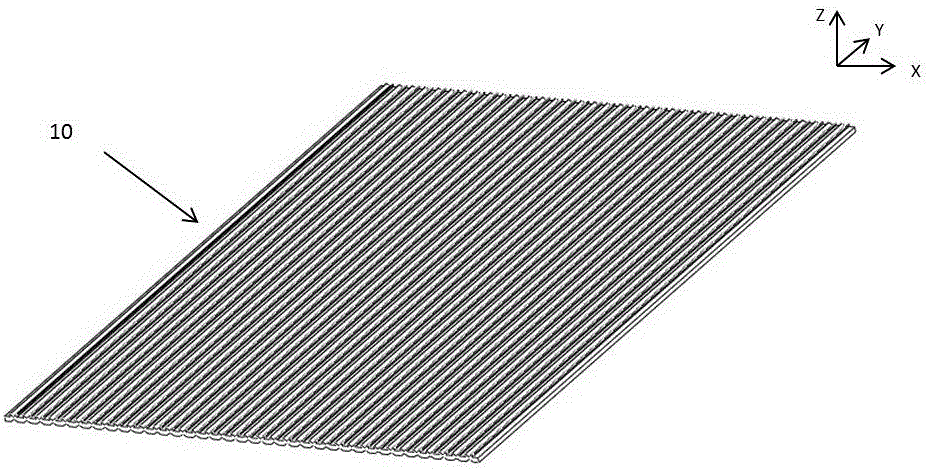

[0032] Combine below Figure 3 to Figure 7 , to describe the optical element of the present invention.

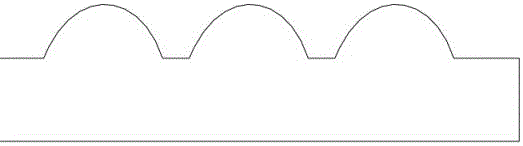

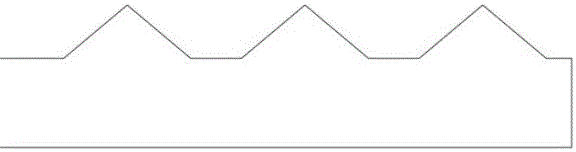

[0033] An optical element 10 includes a substrate 16 having opposite upper and lower surfaces 14 , 15 and a pair of sidewalls 17 , 18 . The upper surface 14 of the substrate is the light-emitting surface of the optical element, and a plurality of first microstructure units 12 are arranged at intervals on the upper surface. The first microstructure units 12 protrude from the upper surface 14, and the bottom 122 of the first microstructure unit is arranged on On the upper surface, the top end 121 of the protrusion of the first microstructure unit opposite to the bottom end has a groove structure. A plurality of second microstructure units 13 are arranged at in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com