High antibacterial ferritic stainless steel and preparation method thereof

A ferrite and stainless steel technology, applied in the field of new antibacterial ferritic stainless steel and its preparation, can solve the problem that the sterilization rate cannot reach 90%, and achieve the effect of reducing the killing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

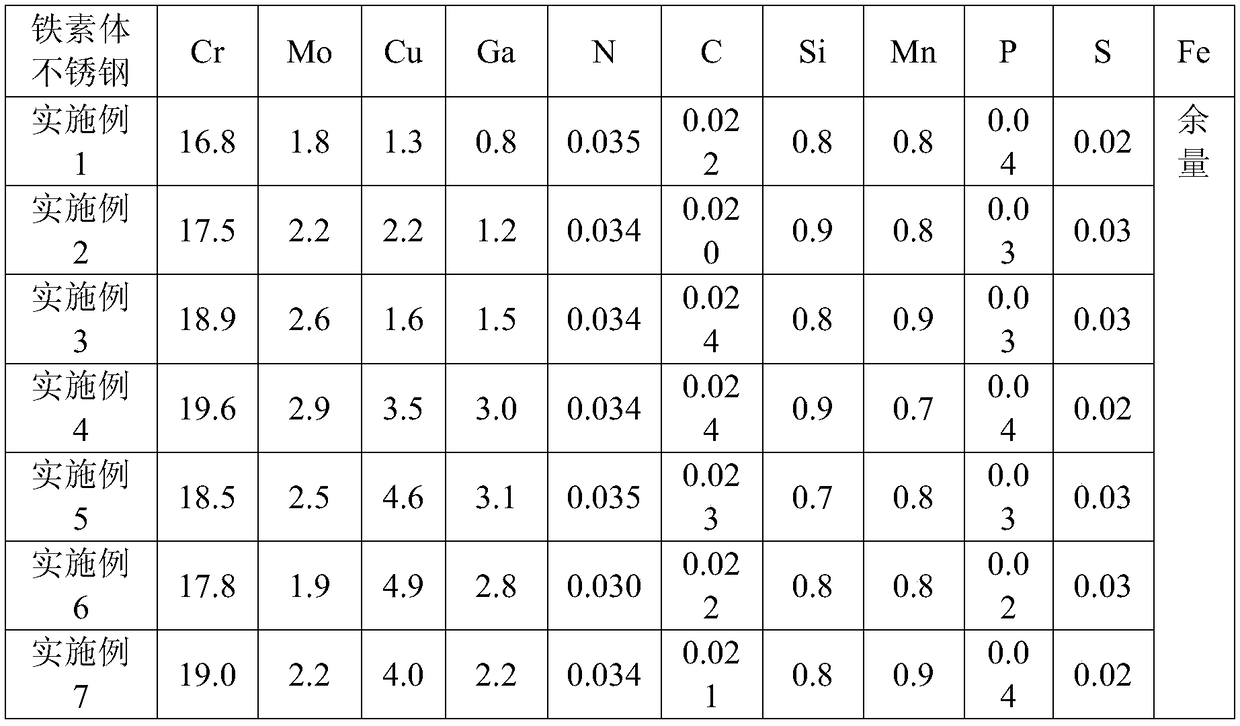

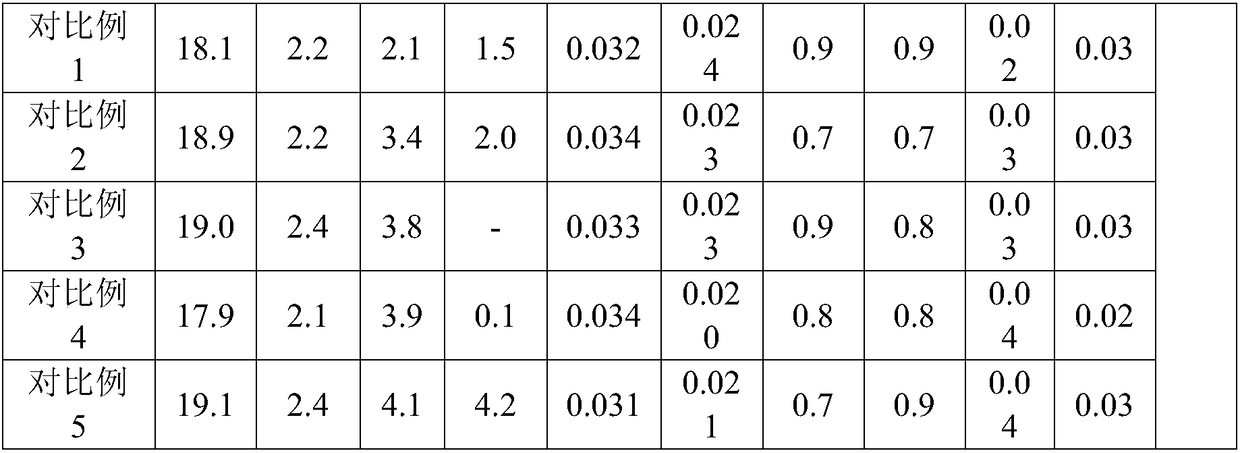

[0024] According to the chemical composition range set by the novel antibacterial ferritic stainless steel material, the present invention adopts 15 kilograms of vacuum induction furnaces to smelt 10 kilograms each of the novel antibacterial ferritic stainless steel forging the embodiment and the comparative example, and its chemical composition is shown in Table 1.

[0025] Antibacterial ferritic stainless steel main chemical composition (wt.%) of table 1 embodiment and comparative example

[0026]

[0027]

[0028] According to the parameter range of the heat treatment method set by the novel antibacterial ferritic stainless steel of the present invention, the detailed parameters of solid solution and aging heat treatment formulated are shown in Table 2.

[0029] The heat treatment process parameter of table 2 embodiment and comparative example

[0030]

[0031]

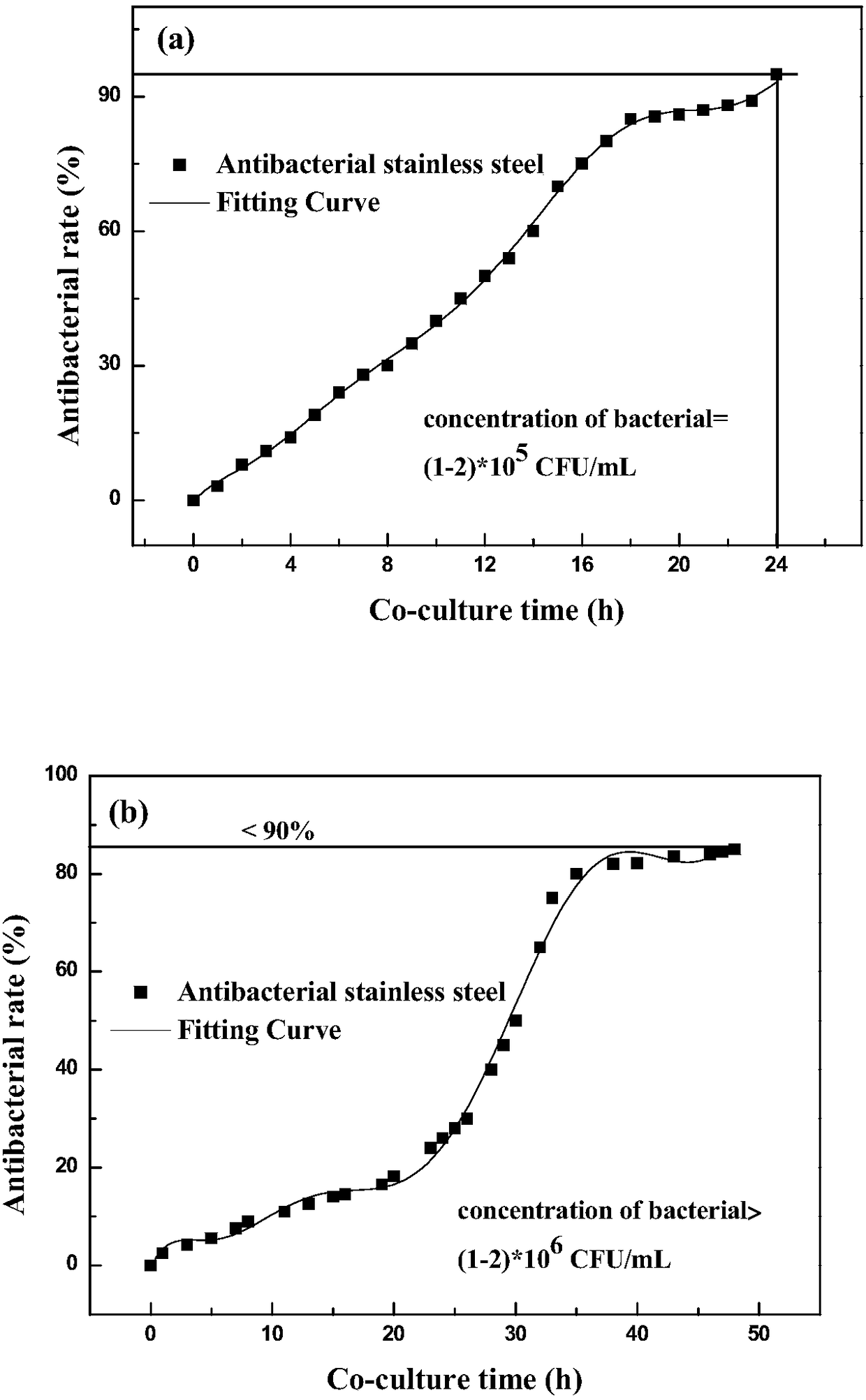

[0032] 1. In vitro antibacterial performance test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com