Differential pressure die rapid water testing tool

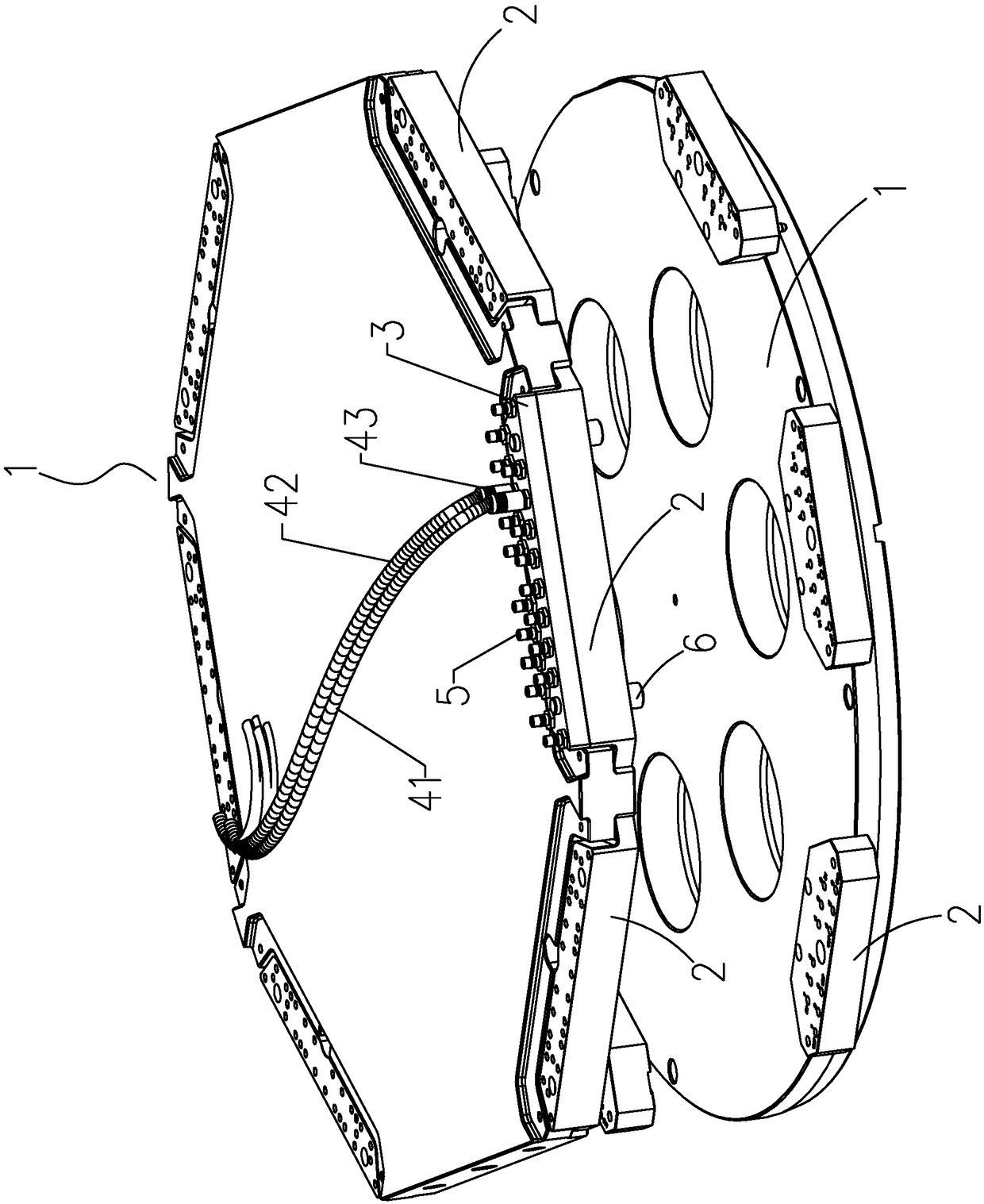

A mold and fast technology, applied in the field of rapid water testing tooling for differential pressure molds, can solve the problems of water leakage at the connection between the water testing joint and the water collecting block, deviation of the water testing results, and low water testing quality, etc., so as to improve the water testing efficiency, Guarantee connection speed and improve the effect of testing water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

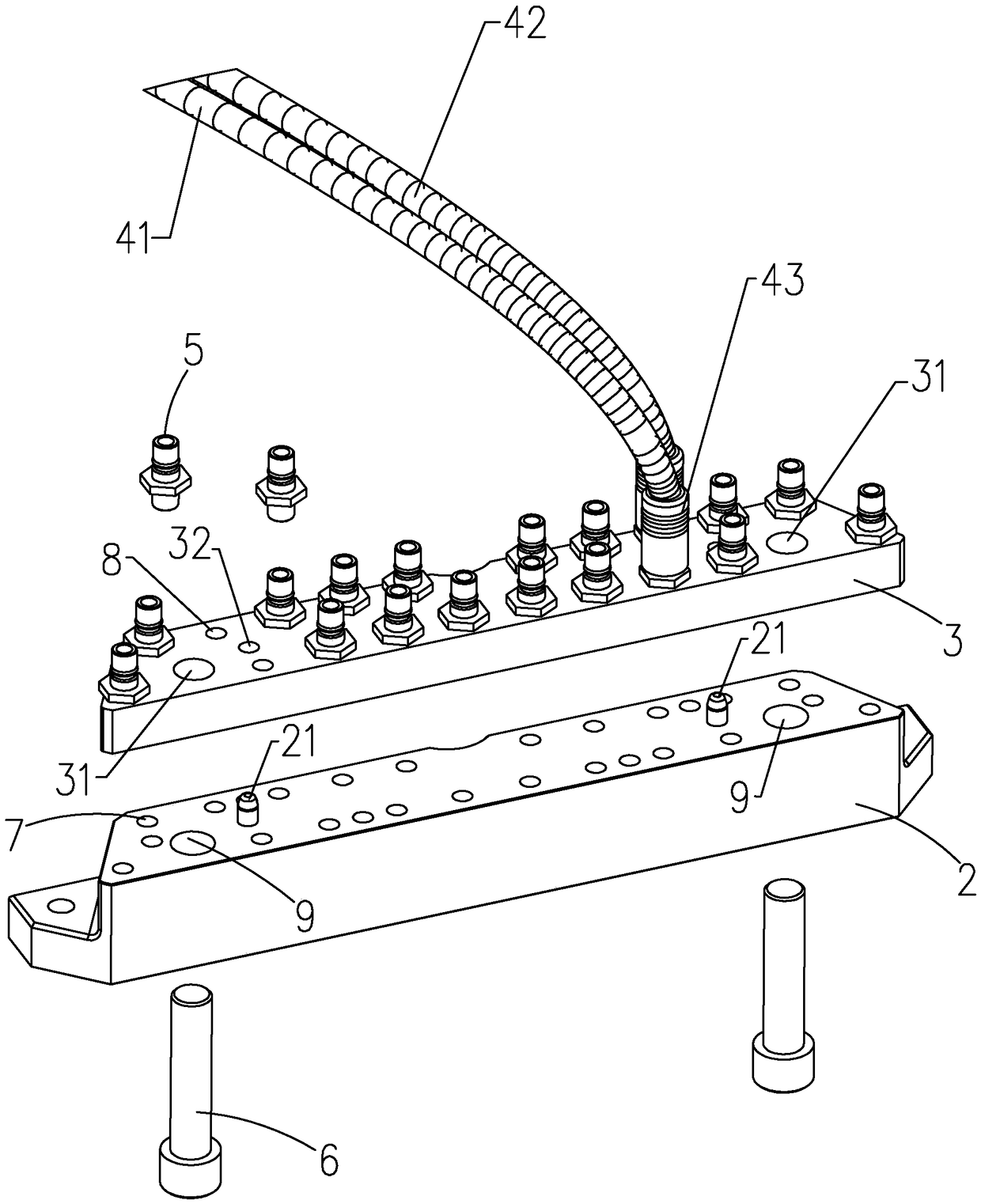

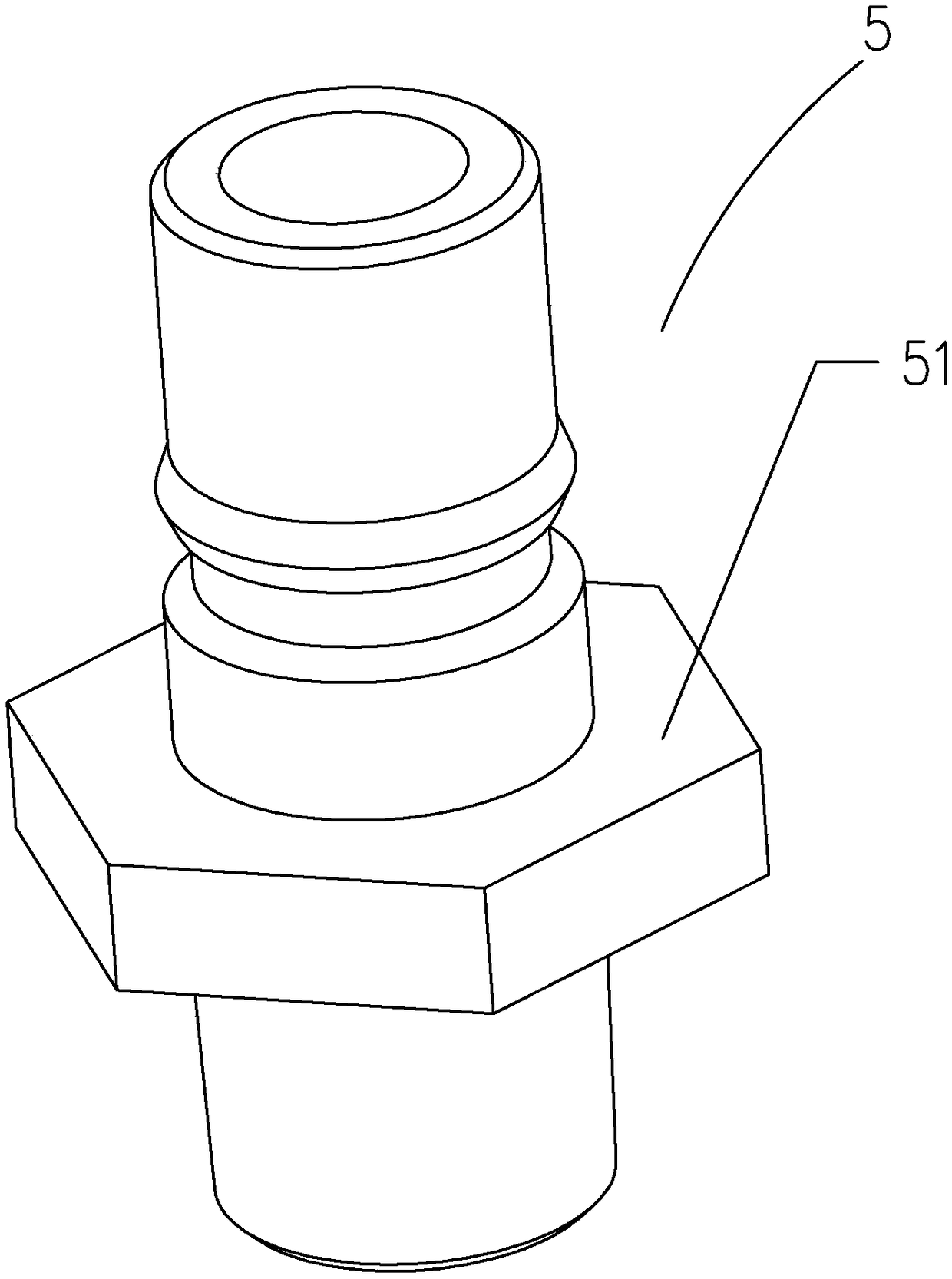

[0021] Embodiment 2, an annular groove (not shown in the figure) is arranged on the outer periphery of the water-through hole 7 on the water collecting block 2, and a matching annular groove is arranged on the corresponding annular groove position on the side where the connecting plate 3 and the water collecting block 2 are connected. The boss (not shown in the figure), the matching between the annular boss and the annular groove realizes the leak-proof tight connection between the water hole 7 and the water guide hole 8 .

[0022] Both of the above two embodiments can realize the quick connection between the water passage hole 7 and the water guide hole 8, and at the same time ensure the performance of preventing water leakage.

[0023] Preferably, the water inlet pipe 41 and the water outlet pipe 42 of the mold water testing machine are made of stainless steel corrugated hose or rubber water pipe. Since the mold water testing machine needs to connect and test the molds in di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com