Closestool water testing machine

A technology for testing water machines and toilets, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., which can solve problems such as low efficiency and high strength, and achieve the effect of reducing labor intensity and improving water testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] There are problems such as high strength and low efficiency in the existing artificial toilet water testing method. Therefore, the present invention proposes a new solution. For a clearer representation, the present invention will be described in detail below in conjunction with the accompanying drawings.

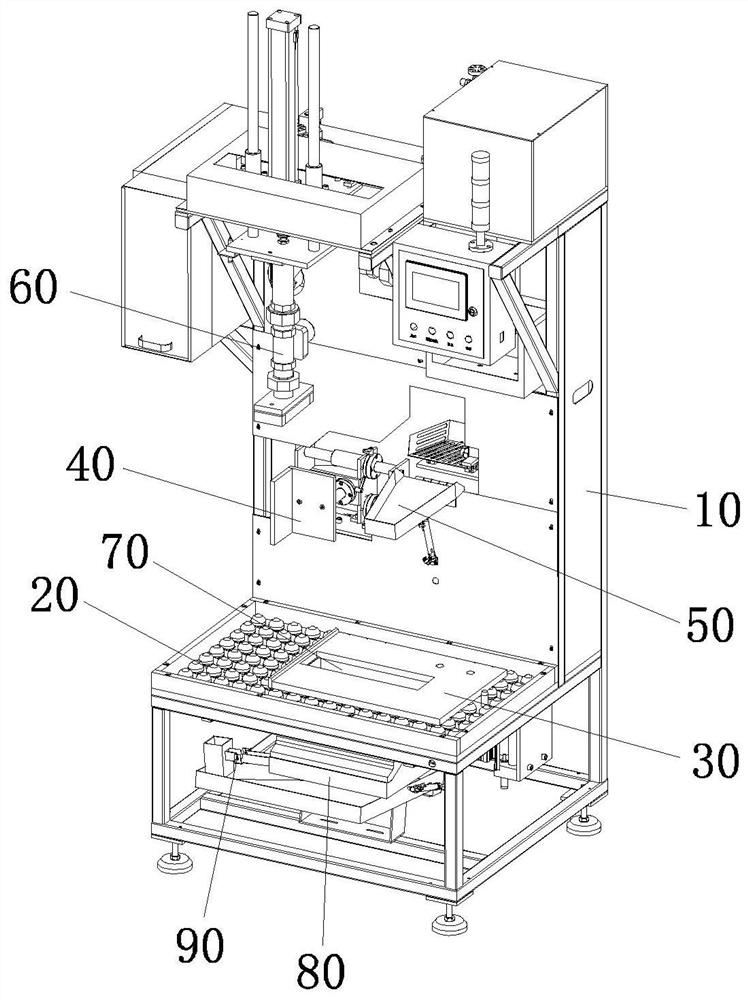

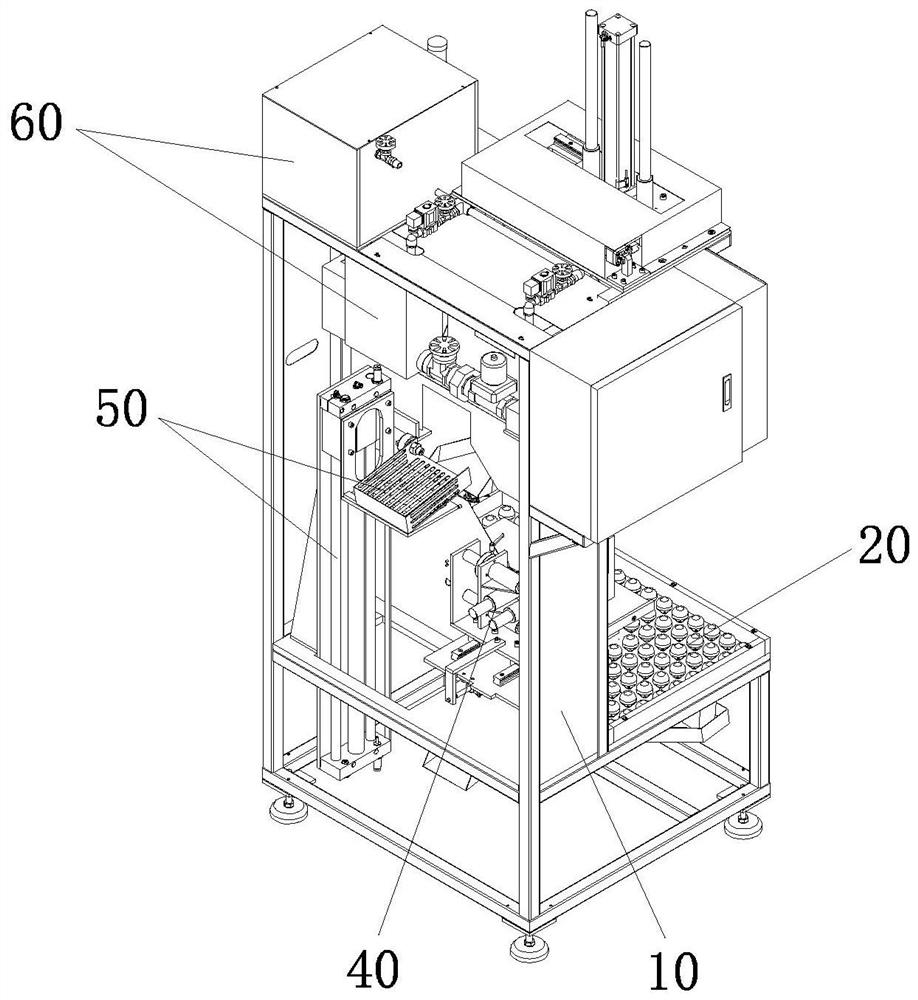

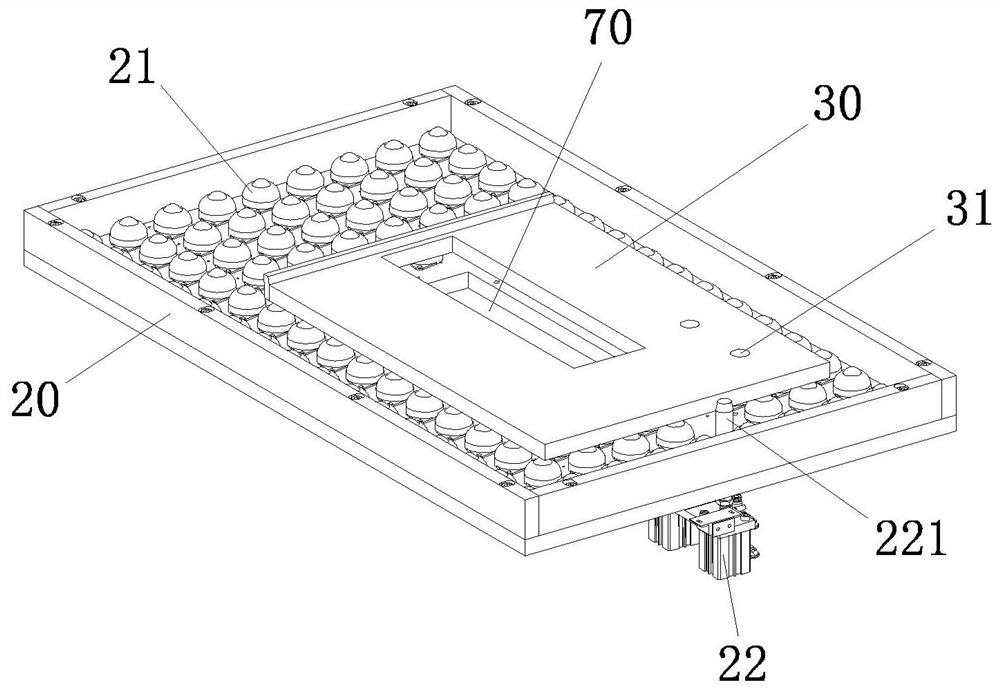

[0030] see Figure 1-2 , a toilet water testing machine, comprising a frame 10 and a test table 20, the test table 20 is provided with a tooling plate 30 for placing the toilet 120 to be tested, and the frame 10 is provided with a frame for adjusting the position of the toilet 120 to be tested The positioning assembly 40, the test ball insertion assembly 50 for adding a test ball into the toilet 120 to be tested and the simulated water injection assembly 60 for releasing water into the toilet 120 to be tested, the tooling board 30 and the test table top 20 Each is provided with a drainage tank 70 for the toilet 120 to be tested to discharge water, and the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com