Unmanned aerial vehicle with four-shaft cone power structural layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

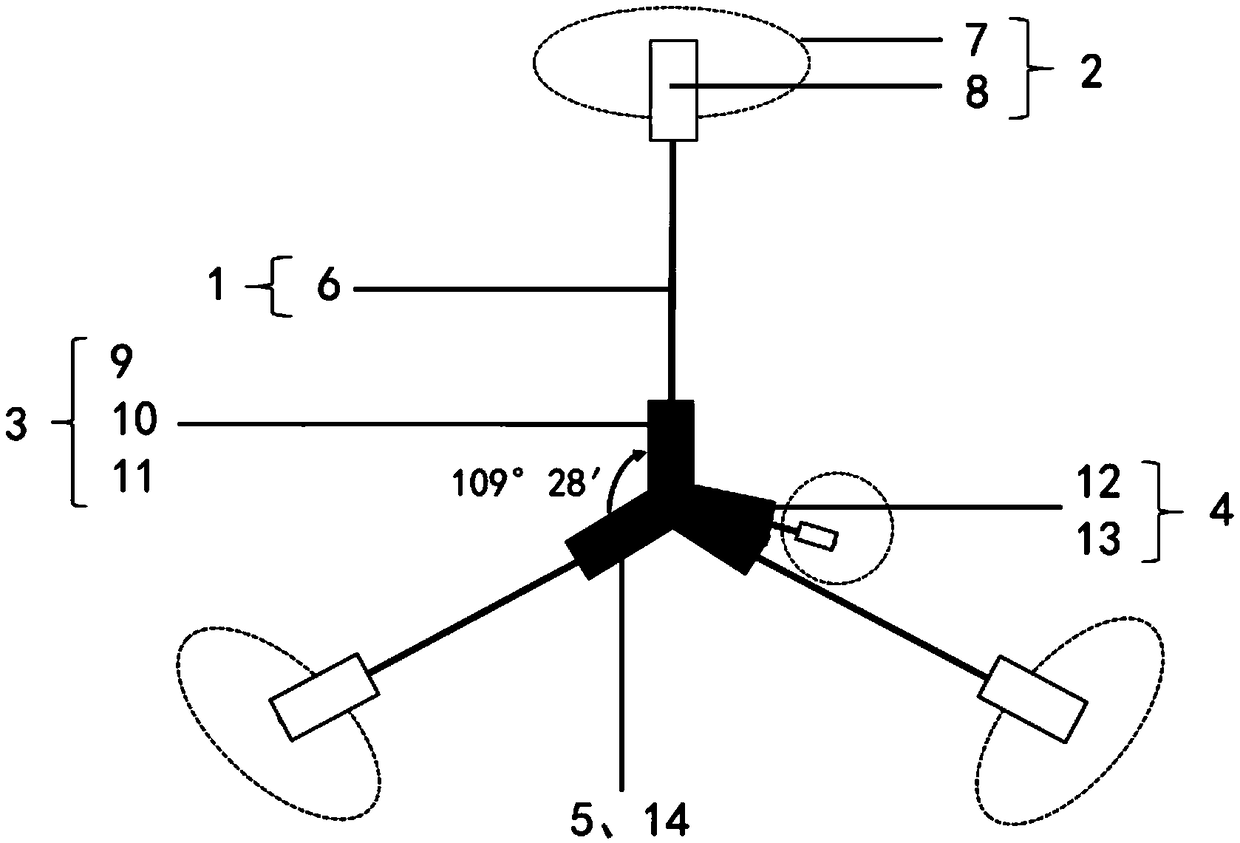

[0025] An unmanned aerial vehicle with a four-axis cone dynamic structure layout, such as figure 1 As shown, it includes a fuselage 1 , a power system 2 , a flight attitude sensing system 3 , a control system 4 and a power supply 5 .

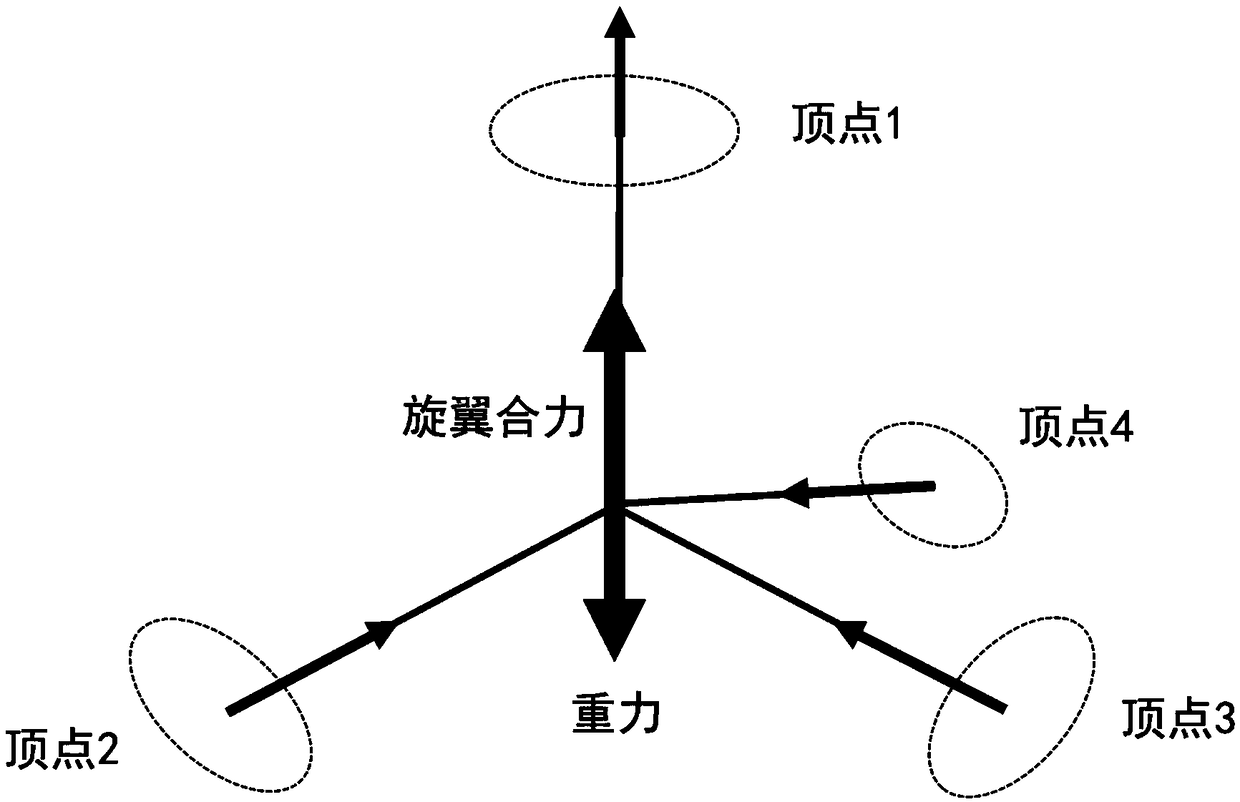

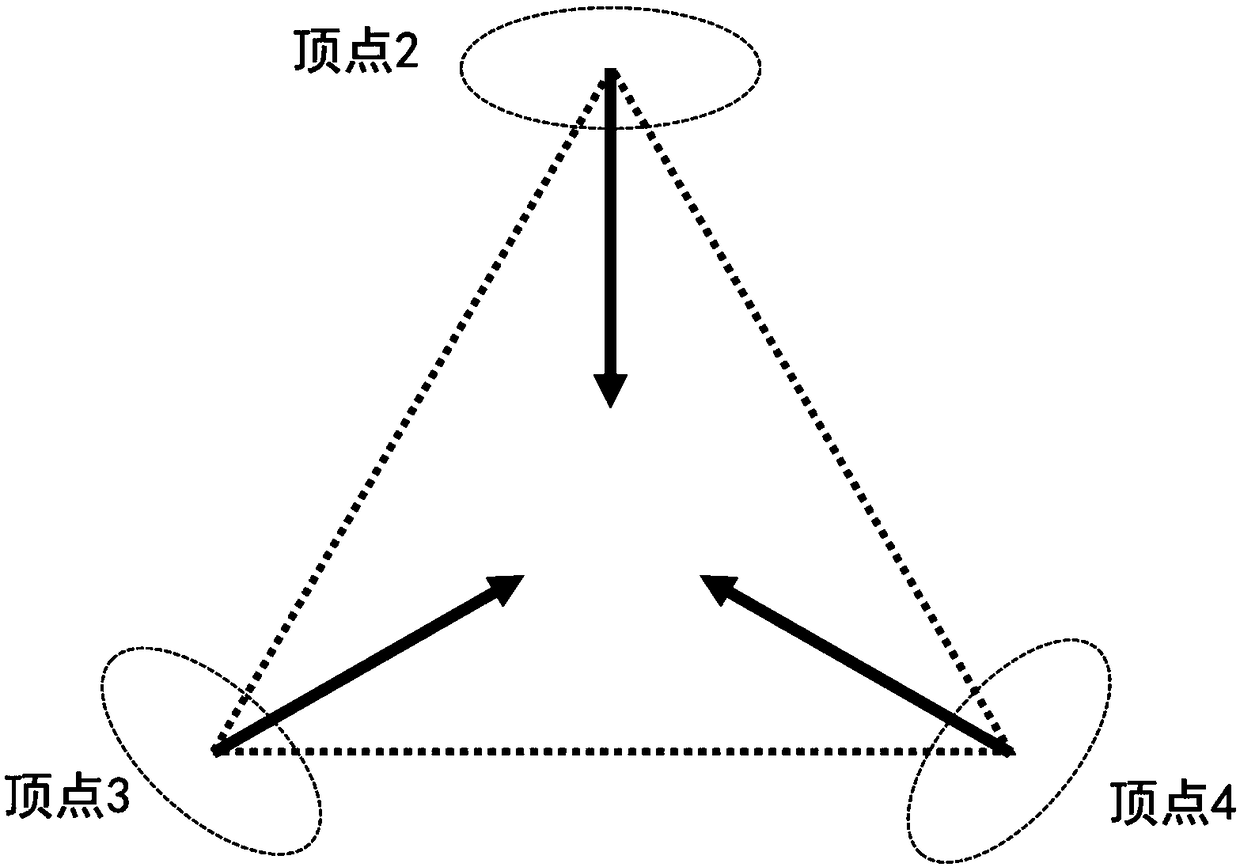

[0026] Described fuselage 1 adopts and comprises four frames 6 that are equal in length, and the four frames are connected at the same point and are radially distributed, and the angles between the four frames are 109 ° 28 '; the four frames The four vertices of the frame, the connecting line between the vertex 1, the vertex 2, the vertex 3 and the vertex 4 constitute a pyramid-shaped regular tetrahedron, and the connecting lines of any three vertices form a regular triangle;

[0027] Preferably, the frame 6 is made of aluminum and fiberglass, which can ensure strength and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com