Horizontal opening and closing roof structure

A cover structure, horizontal technology, applied in the direction of roof, building components, building structure, etc., can solve the problem of the research lag of opening and closing roof, and achieve the effect of reducing driving requirements and control difficulty, small space, and high overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

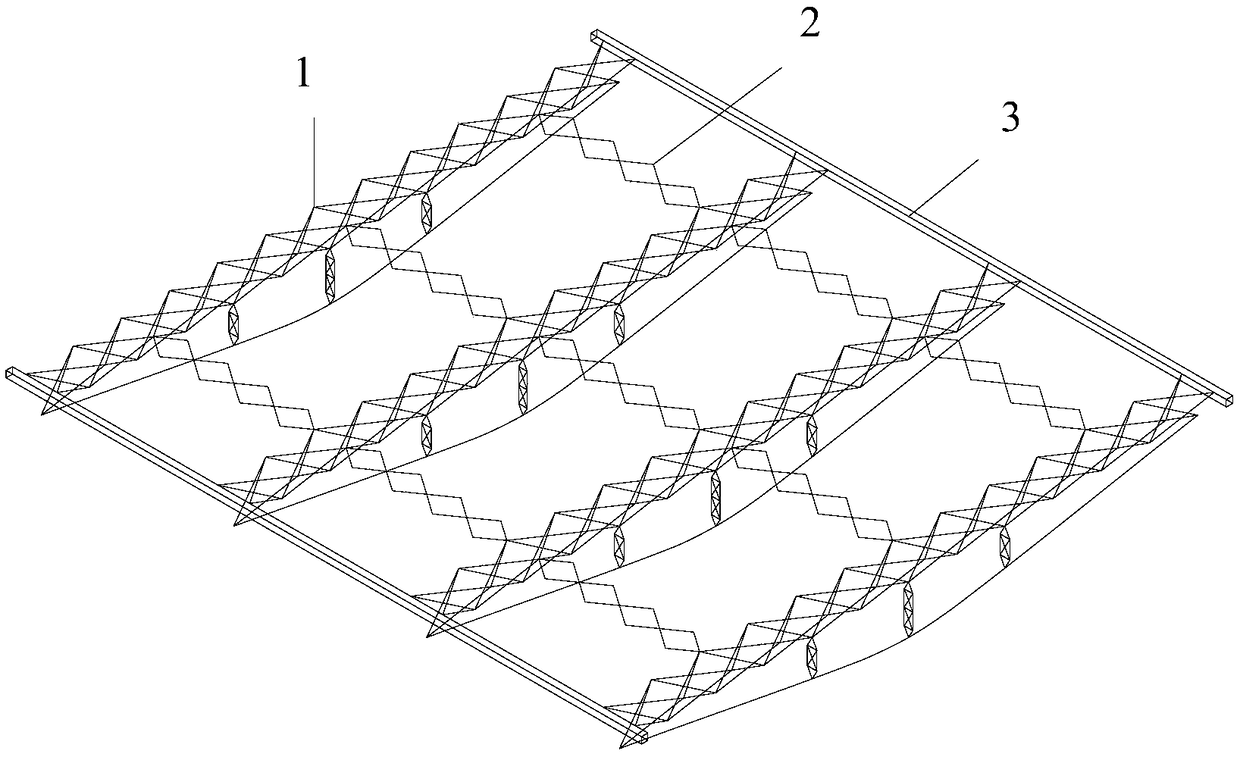

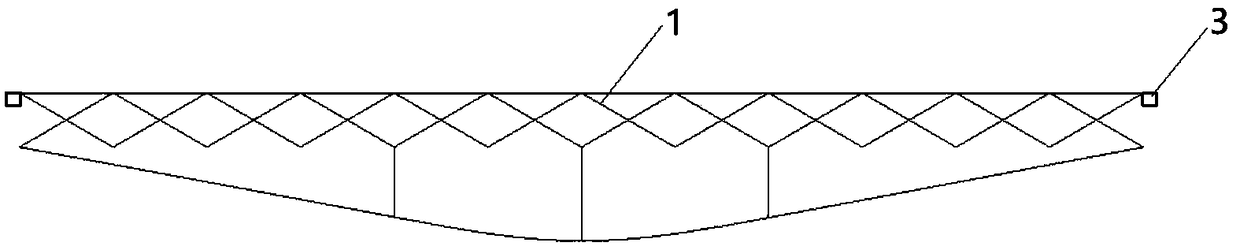

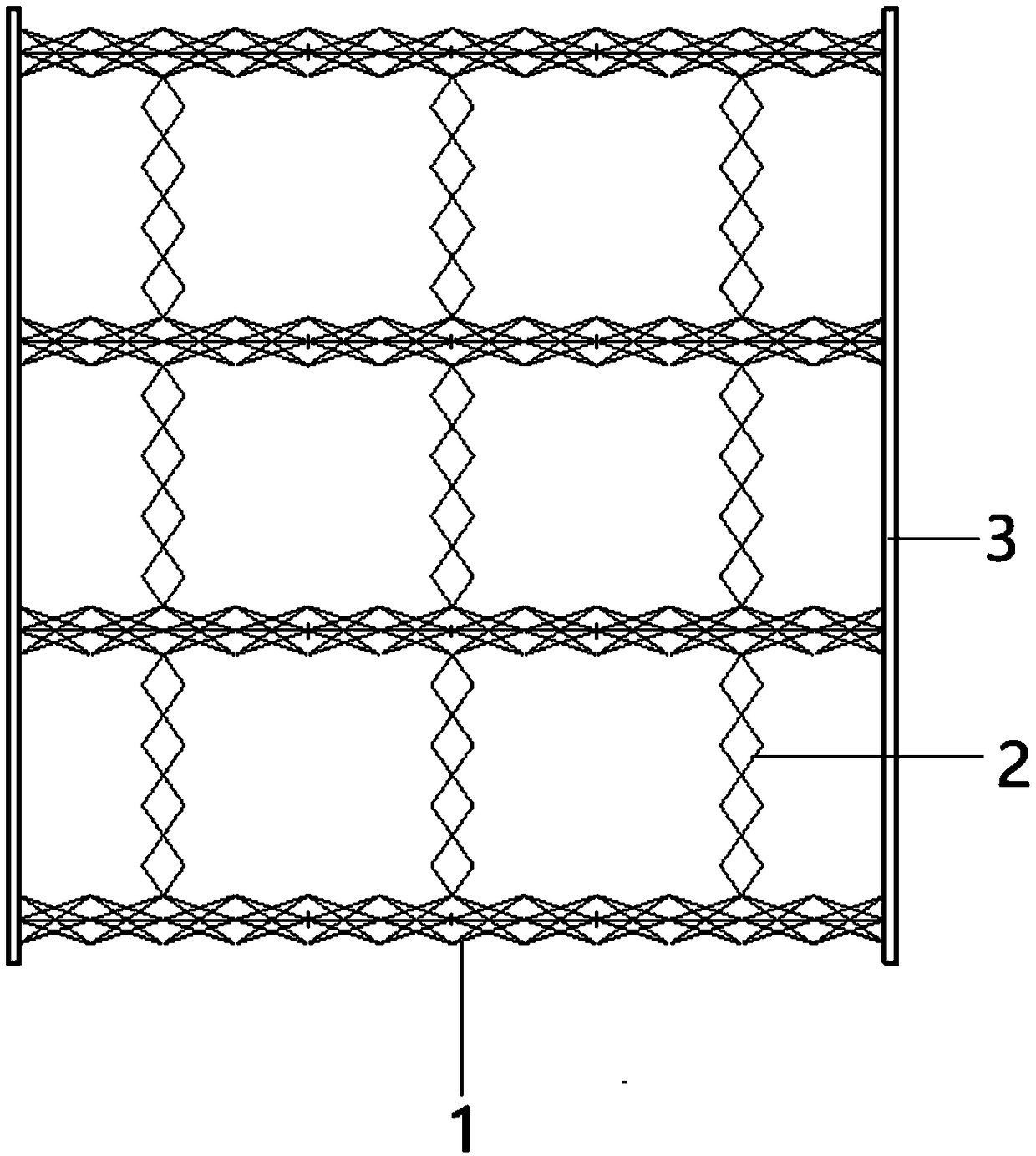

[0042] Such as figure 1 , 2As shown in and 3, a horizontal opening and closing roof structure consists of more than two horizontal space scissor mechanisms 1, more than two longitudinal chain scissor mechanisms 2, and two through-length chains that slide horizontally on the roof truss 4. Composed of rods 3, the horizontal space scissor mechanism 1 is evenly arranged in the longitudinal direction, and its two ends are respectively connected to a long connecting rod 3, and can only slide longitudinally, and cannot move in other directions. The rod 3 is used to control the synchronous deployment and retraction of all the horizontal space scissor mechanisms 1 , and the longitudinal chain scissor mechanisms 2 are evenly arranged between adjacent horizontal space scissor mechanisms 1 in the transverse direction.

[0043] Such as Figure 4 , 5 As shown, the transverse spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com