Buckle structure and automobile lamp

A technology of a buckle structure and a car lamp, which is applied in the directions of motor vehicles, road vehicles, lighting devices, etc., can solve the problems of low installation efficiency and cannot guarantee effective fixing, and achieve the effect of high installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

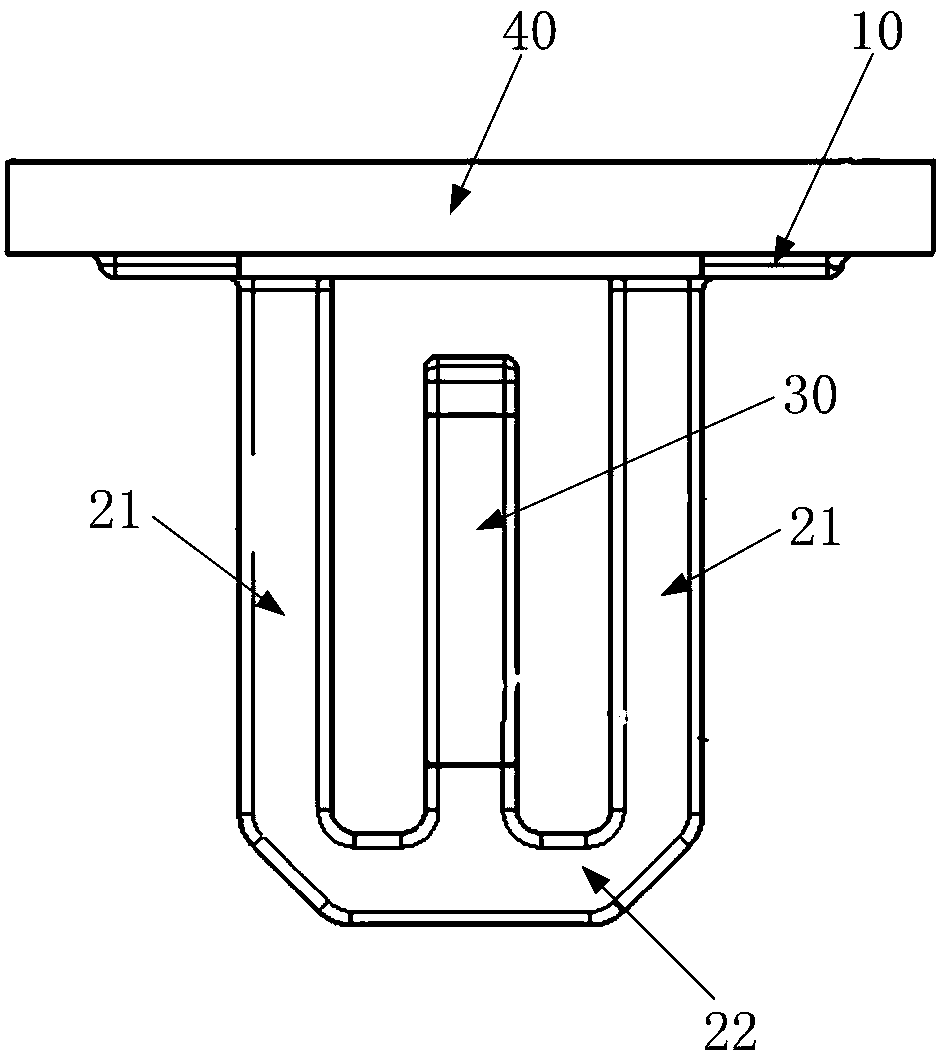

[0037] like Figure 1-Figure 6 As shown, the buckle structure provided by the embodiment of the present invention includes:

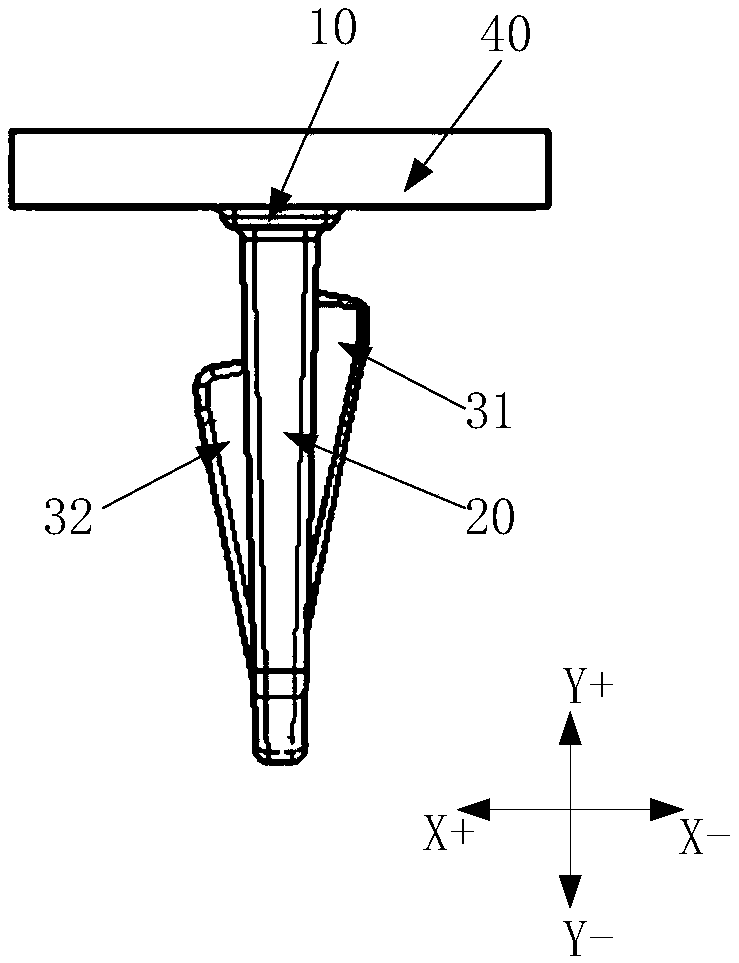

[0038] The buckle structure provided by the embodiment of the present invention includes: a fixed arm 20 and an elastic cantilever 30 , the fixed arm 20 is used for connecting with the first component 40 , the elastic cantilever 30 is connected with the fixed arm 20 , the opposite side edges of the elastic cantilever 30 are A first pressure tongue 31 and a second pressure tongue 32 are respectively provided in the vertical direction, and the distance between the first pressure tongue 31 and the fixed end of the fixed arm 20 is smaller than the distance between the second pressure tongue 32 and the fixed end of the fixed arm 20 . distance.

[0039] In a specific implementation of this embodiment, the fixed end of the fixed arm 20 may be directly connected to the first component 40, or, in another specific implementation of this embodiment, the fixed end...

Embodiment 2

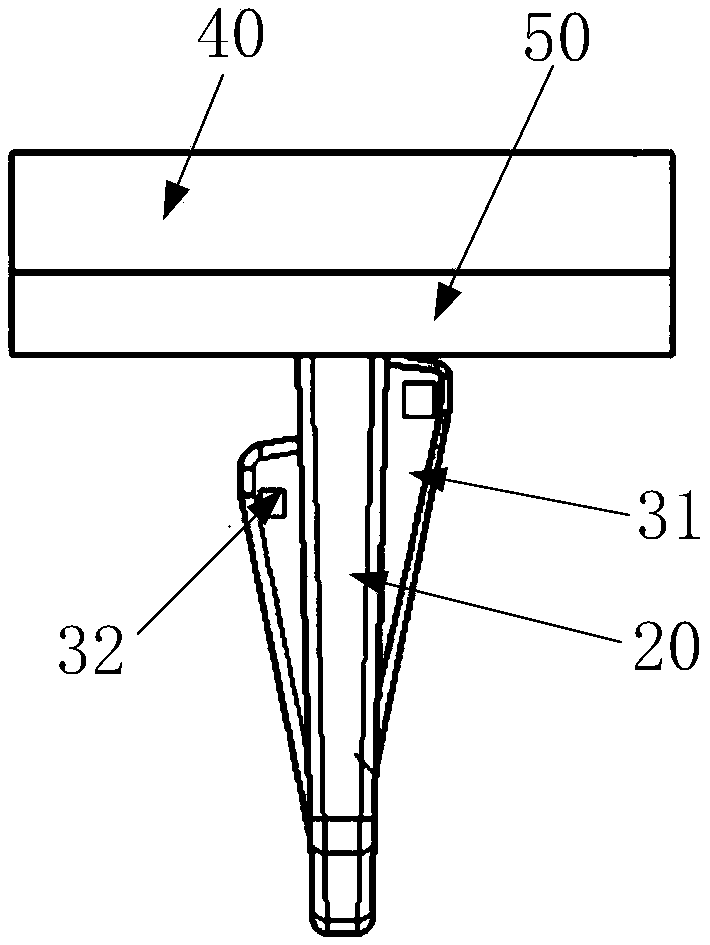

[0063] The second embodiment provides a vehicle lamp, including: a first part 40 , a second part 50 and the buckle structure provided in the first embodiment above. The mounting plate 10 of the buckle structure is connected to the first part 40 , and the second part 50 The second component 50 is located between the first pressing tongue 31 of the buckle structure and the first component 40 by connecting with the first component 40 through the buckle structure.

[0064] Further, the vehicle lamp further includes a third part 60 , and the third part 60 is located between the second part 50 and the second pressing tongue 32 of the buckle structure.

[0065] The first part 40 , the second part 50 and the third part 60 are all parts in the lamp, and the first part 40 , the second part 50 and the third part 60 are connected by a snap structure.

[0066] In specific implementation, in figure 2 In the direction of the coordinate system shown, the thickness of the second part 50 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com