Equipment for pvc film processing

A film treatment and frame technology, applied in applications, household appliances, other household appliances, etc., can solve the problem of being unable to be ironed by corona, improve the product qualification rate and service life, good ironing effect, and improve flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

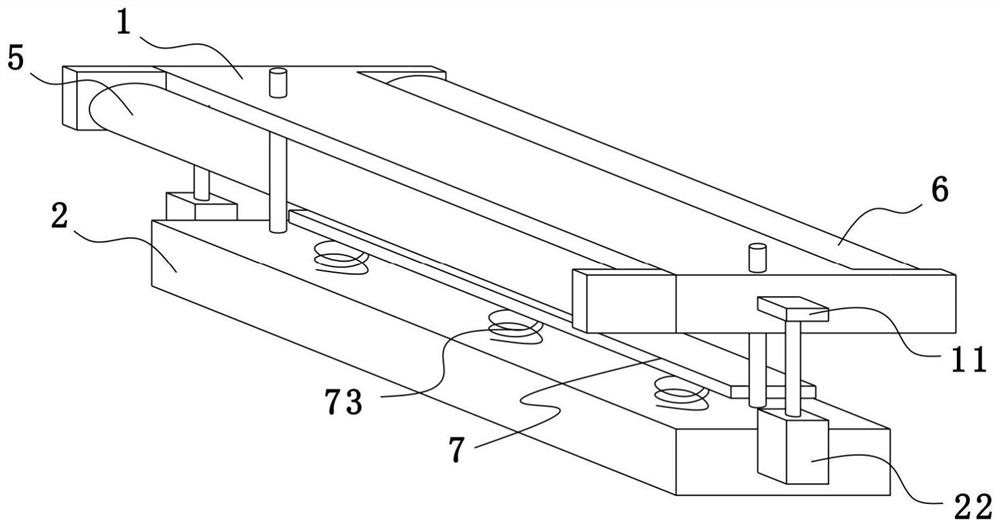

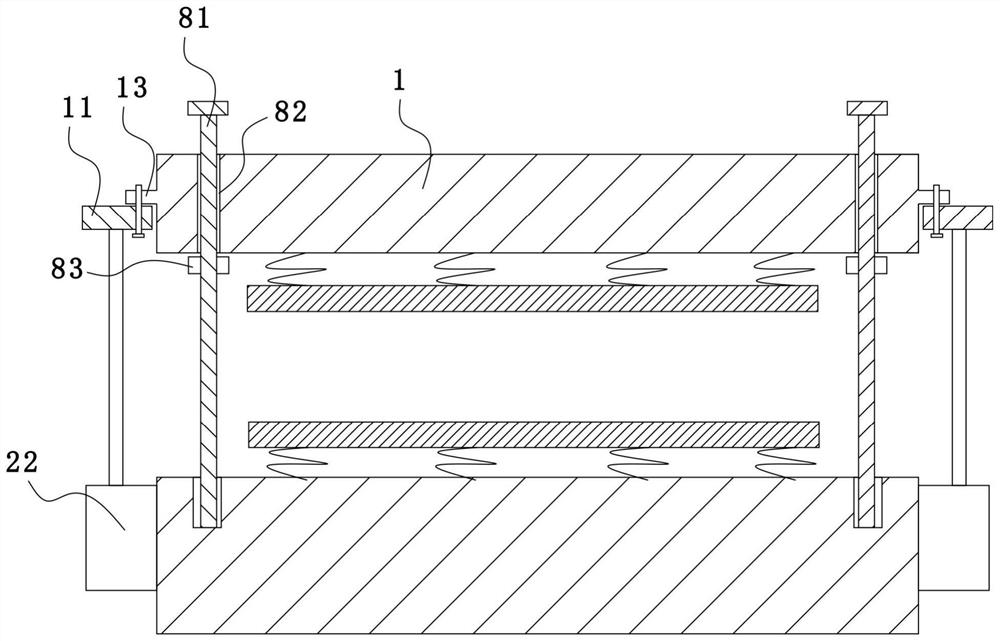

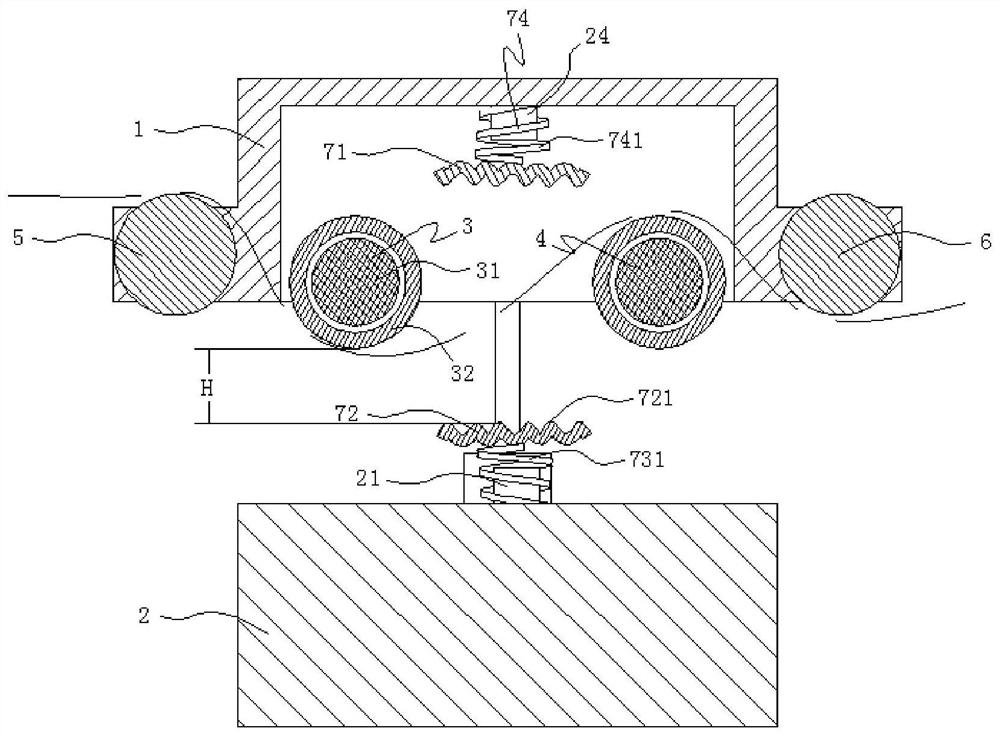

[0019] like Figure 1-4 As shown, a device for PVC film processing includes an upper frame 1, a lower frame 2, a first display member 3 and a second display member rotatably arranged between the upper and lower frames 4. The upper frame is provided with a first feeding member 5 that cooperates with the first display member 3 and a second feeding member 6 that cooperates with the second display member 4. The upper, There is a corona device 7 used to generate corona to level the material between the lower frames; the corona device can emit corona or arc when energized to iron the PVC film, thus ensuring good flatness of the PVC film , not only effectively solve the problem of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap