Bottle cleaning and filling machine

The technology of filling machine and transmission mechanism is applied in the field of cleaning mechanism, which can solve the problems of reducing the concentration or purity of cleaning liquid, reducing the cleaning effect of the cleaning machine, reducing the service life of the equipment, etc., so as to improve the effect, improve the reliability and use of the equipment. Longevity, avoid the effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

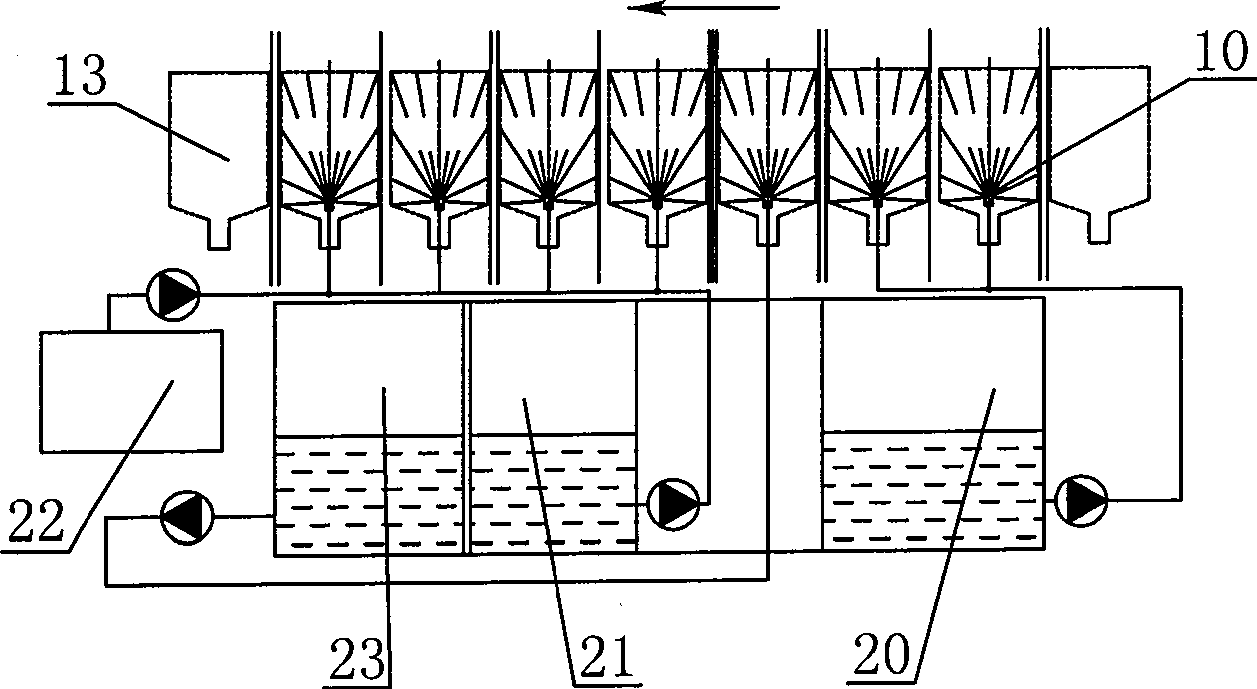

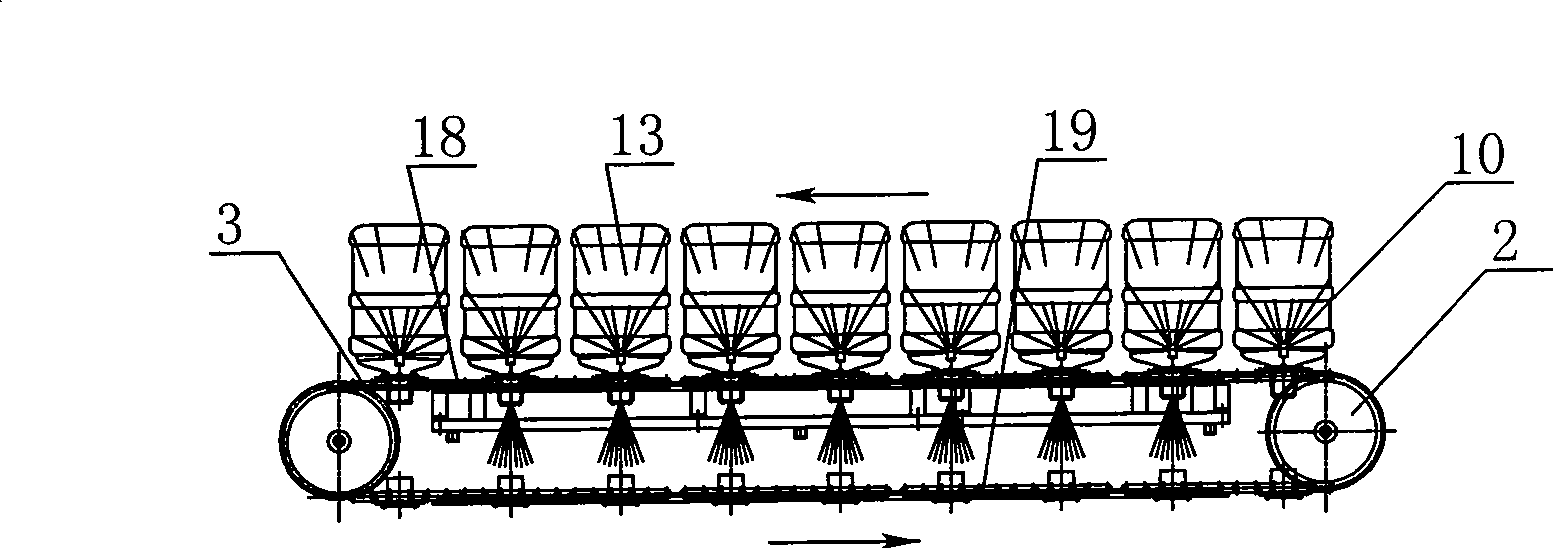

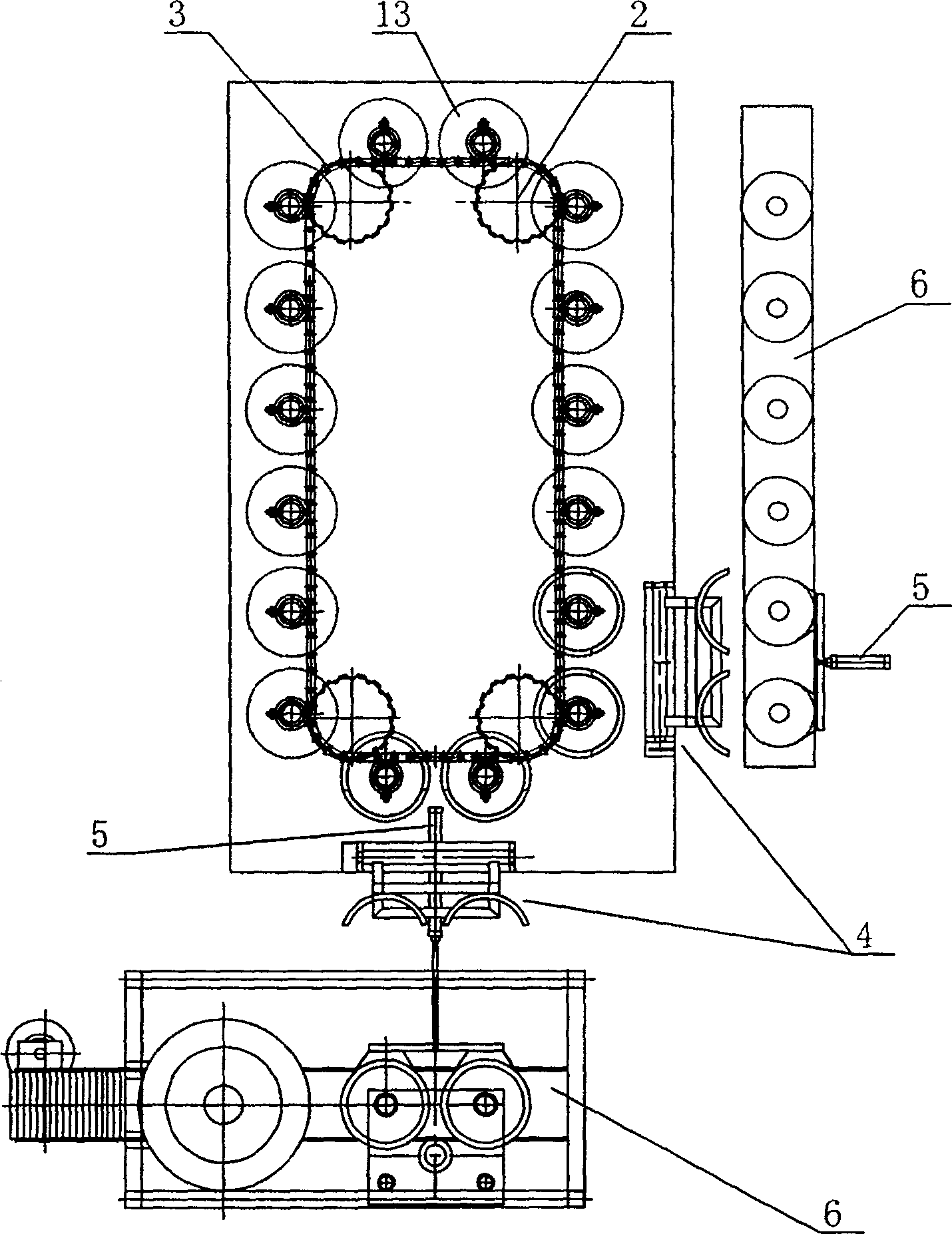

[0034] See Figure 3 to Figure 7 , a cleaning and filling machine (the cleaning and filling machine is used to clean and fill five-gallon buckets 13), comprising a circulation transmission mechanism, on which a plurality of bucket fixing parts 1 are arranged, and on the circulation transmission mechanism Cleaning water tanks such as alkaline water tank, liquid medicine tank and finished product water tank are arranged below, and the circulation transmission mechanism is driven by a rotating body, and the axis of the rotation body is perpendicular to the ground so that the circulation transmission mechanism forms a horizontal circulation transmission.

[0035]The rotating body is a sprocket 2, and there are four sprockets 2, and the axis line of the four sprockets 2 is a rectangle; the circulating transmission mechanism is a transmission chain 3, and the four sprockets 2 and the transmission chain 3 Engage to drive the transmission chain 3 horizontal circulation transmission. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com