A kind of bentonite waterproof system and construction method

A technology of bentonite waterproof blanket and construction method, which is applied in infrastructure engineering, protective devices, buildings, etc., and can solve problems such as insufficient net content of bentonite, large thickness, and impractical fixation of waterproof blanket, so as to achieve reliable waterproof system and prevent water leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

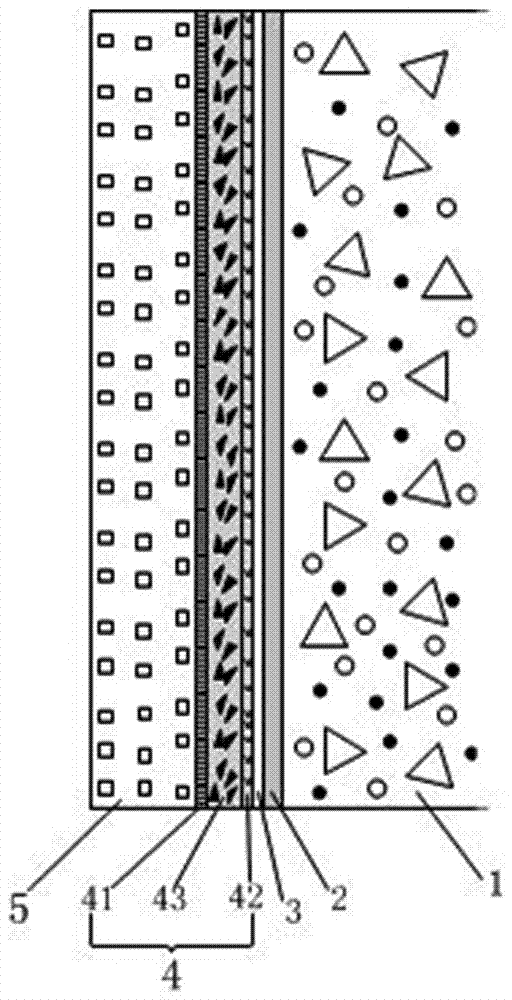

[0079] A waterproofing system such as figure 1 As shown, the waterproof system is composed of concrete structure base 1, bentonite clay layer 2, PE film 3 and bentonite waterproof blanket 4 from the concrete structure base to the outside, wherein the bentonite waterproof blanket 4 constitutes the first waterproofing; bentonite clay layer 2 It is composed of continuous and uniform bentonite clay, which constitutes the second waterproofing of the present invention. At the same time, under the pressure of the backfill soil layer 5 and the protective layer, the bentonite clay has been squeezed and combined with the concrete, and some will penetrate into the void of concrete to form a third waterproofing. It should be noted that the double-layer waterproofing of such a structure is by no means a simple superposition of double-layer waterproofing. It is essentially different from the waterproof system constructed with double-layer waterproof blankets. Taking the waterproof project ...

Embodiment 11

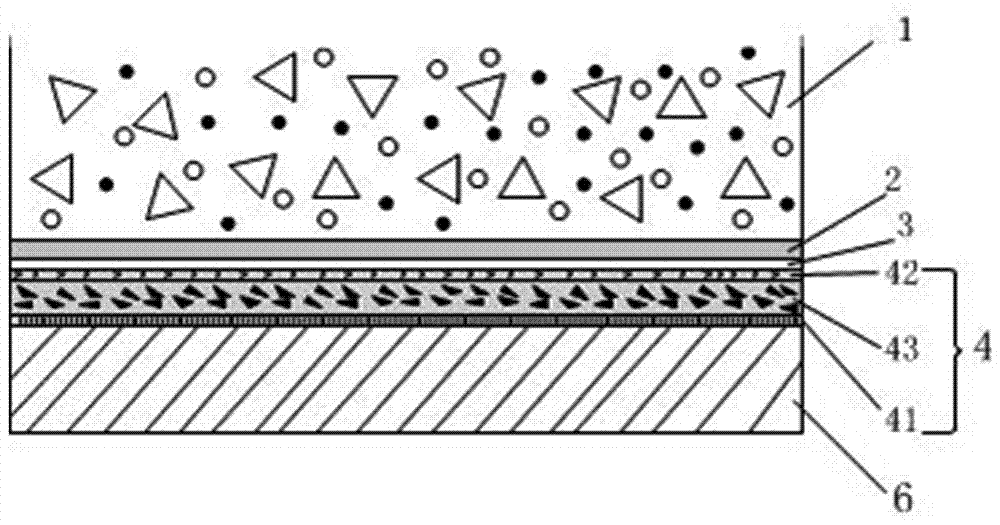

[0087] A bentonite waterproofing system such as figure 2 As shown, it is composed of concrete cushion 6, non-woven fabric layer 41, bentonite layer 43, woven fabric layer 42, PE film 3, bentonite clay layer 2 and concrete structure base 1 from bottom to top. Bentonite clay can be directly covered on the PE film.

[0088] The bentonite waterproofing system of this embodiment is suitable for base plate construction, that is, before the concrete construction of the building, some special parts need to be waterproofed first, and then the base plate is used. During the construction of the bottom slab, due to the concrete structure layer, it does not exist (no construction). At this time, the bentonite cement can be replaced by bentonite particles. During the waterproof construction of the bottom slab, after the steel bars are bound, spread the bentonite particles evenly under the steel bar layer. .

Embodiment 12

[0090] A bentonite waterproofing system is different from the above-mentioned embodiments in that bentonite powder is attached to the surface of the bentonite clay layer 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com