Intelligent logistics sorting device

A sorting device and intelligent logistics technology, applied in sorting and other directions, can solve the problems of occupying a lot of space, increasing sorting errors, and high error rates, improving efficiency, reducing space requirements, and achieving good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

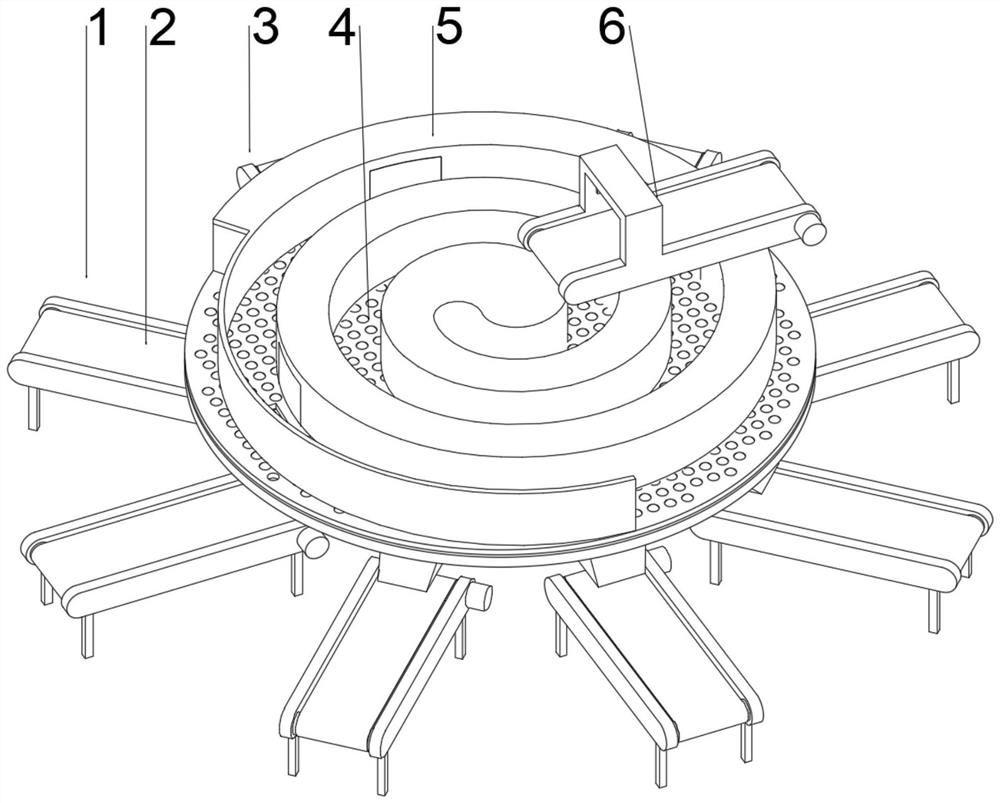

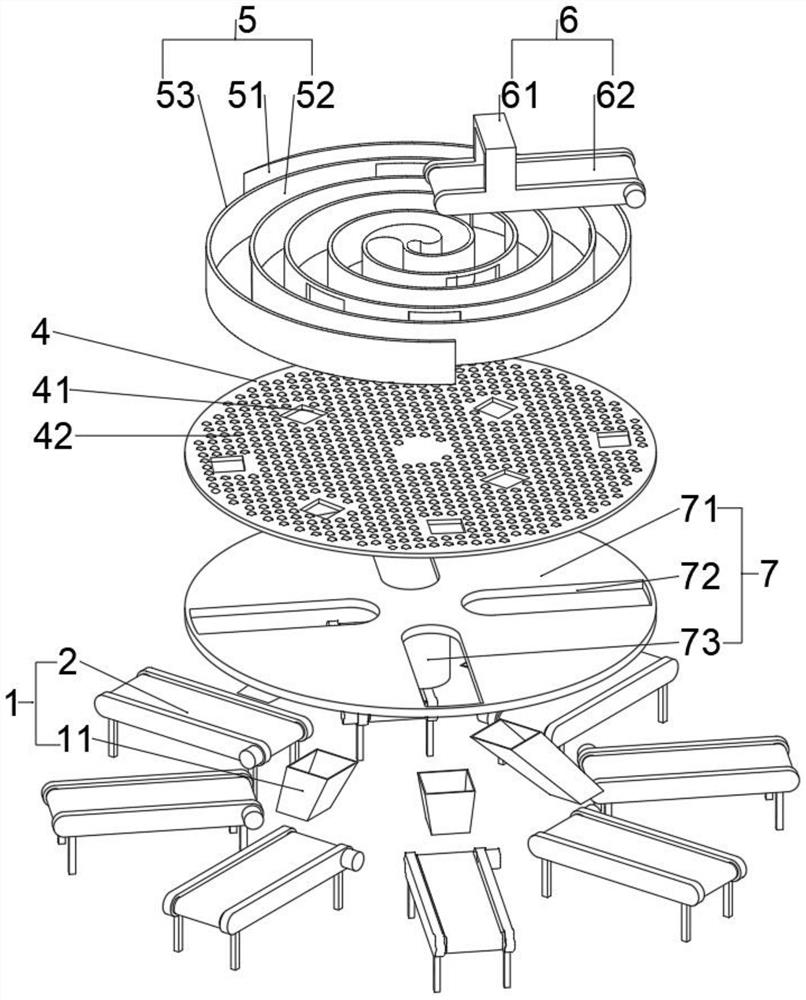

[0028] see figure 1 and 2 , in Embodiment 1 of the present invention, an intelligent logistics sorting device includes a feeding mechanism 6, a diversion mechanism 3 and an output mechanism 1; a corresponding feeding mechanism 6 is installed above the diversion mechanism 3, and the diversion mechanism 3 It includes a diverter plate 4, a diverter assembly 5 and a drive assembly 7. The diverter plate 4 is rotatably mounted with multiple groups of balls 42 protruding from the surface of the diverter plate 4 on both sides. The drive assembly 7; the splitter assembly 5 includes a track box 53 installed on the surface of the splitter disc 4, and the track box 53 divides the splitter disc 4 surface into a double-helix parallel flow track 52 and a discharge track 51; the splitter A plurality of discharge openings 41 are provided on the disk 4 in the area corresponding to the discharge track 51, and a through groove 55 corresponding to the discharge opening 41 is provided on the side ...

Embodiment 2

[0033] see Figure 1~6, the main difference between this embodiment 2 and embodiment 1 is:

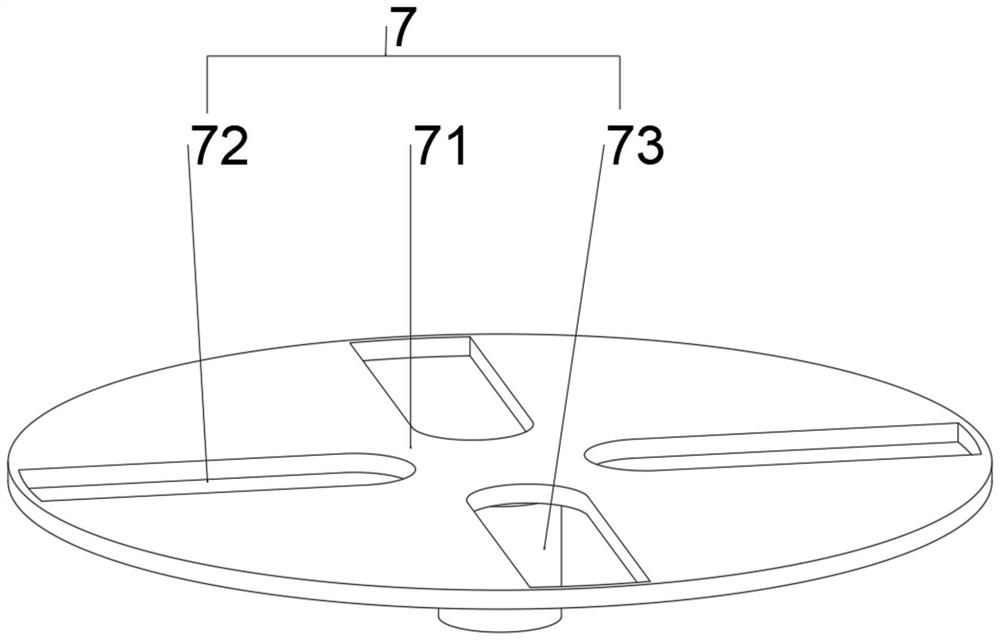

[0034] see figure 1 , figure 2 and image 3 , in Embodiment 2 of the present invention, the drive assembly 7 includes a drive plate 71 and a primary motor 73, the drive plate 71 is connected to the primary motor 73, and the drive plate 71 is coaxially connected with the diverter plate 4; The surface of the driving disk 71 is in pressure contact with the ball 42, and the driving disk 71 is provided with a plurality of through grooves 72 along its diameter. The driving assembly 7 is used to drive the balls 42 to rotate. The driving disc 71 can rotate under the drive of the primary motor 73. Since the driving disc 71 is in pressure contact with all the balls 42, and the balls 42 cannot leave their positions, the balls 42 will Autorotation occurs under the action of the driving disc 71 to form a drive. Because the driving disc 71 is located below the diverter disc 4, it prevents the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com