Transmission mechanism and washing machine

A technology of a transmission mechanism and a washing machine, which is applied in the field of washing machines, can solve the problems of poor stability of the delivery box and large occupied space and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

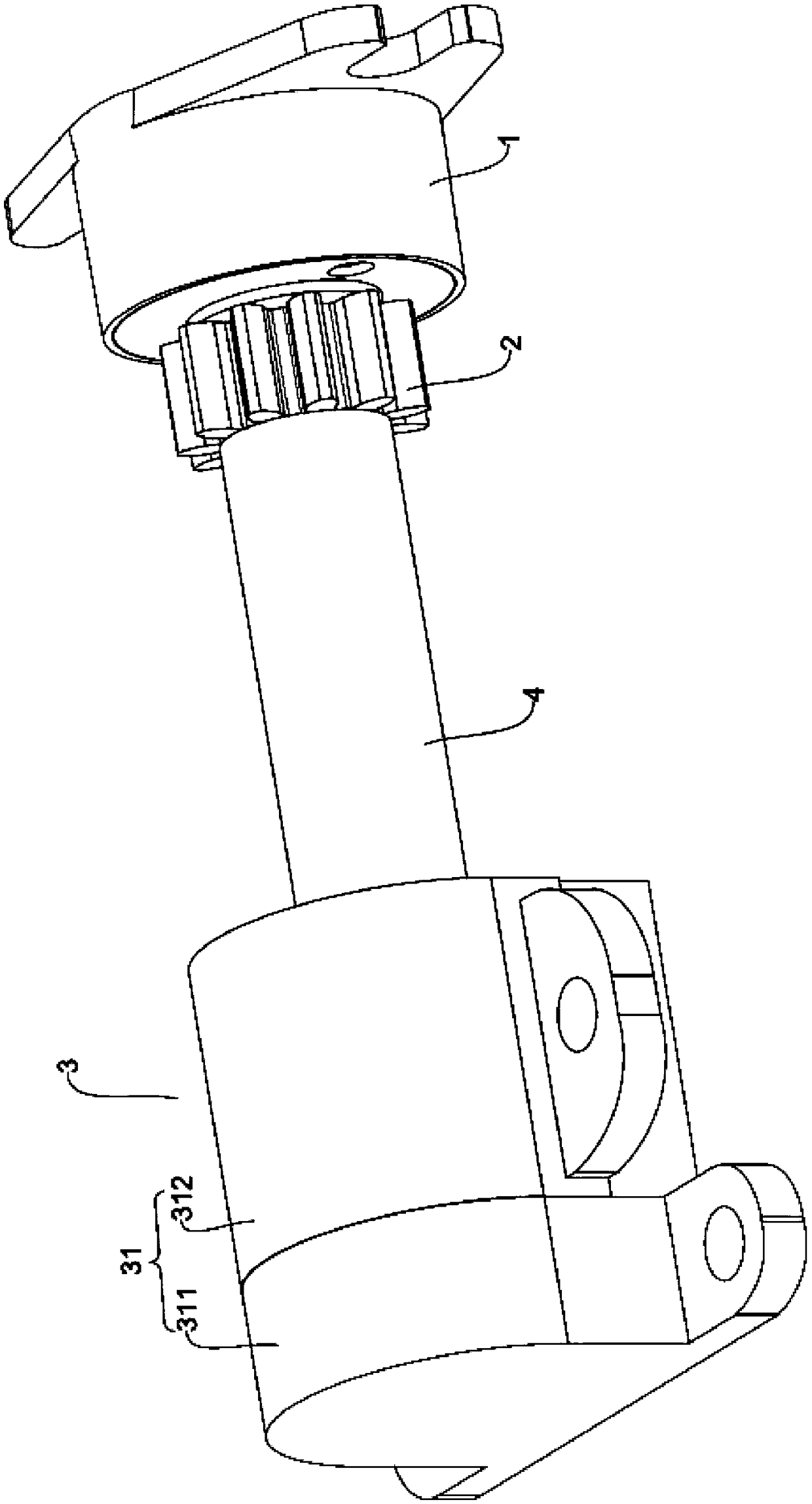

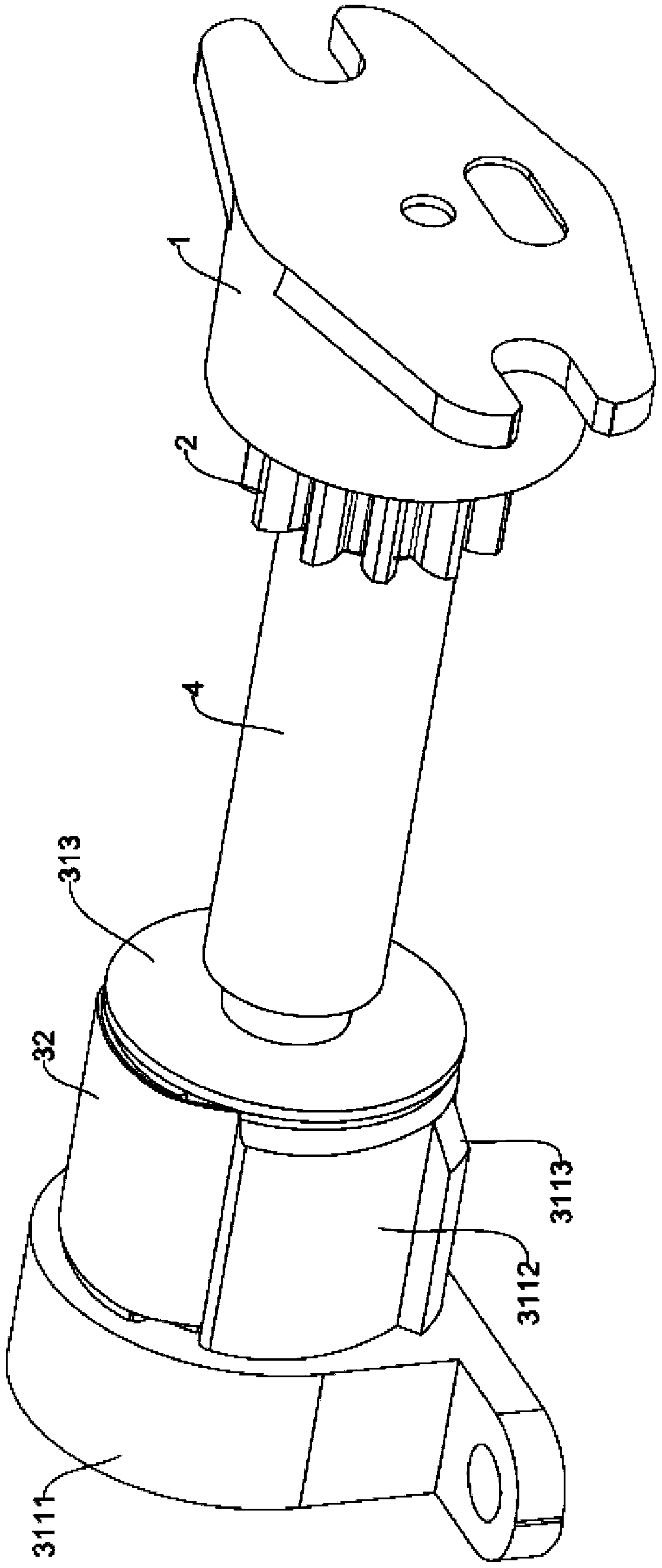

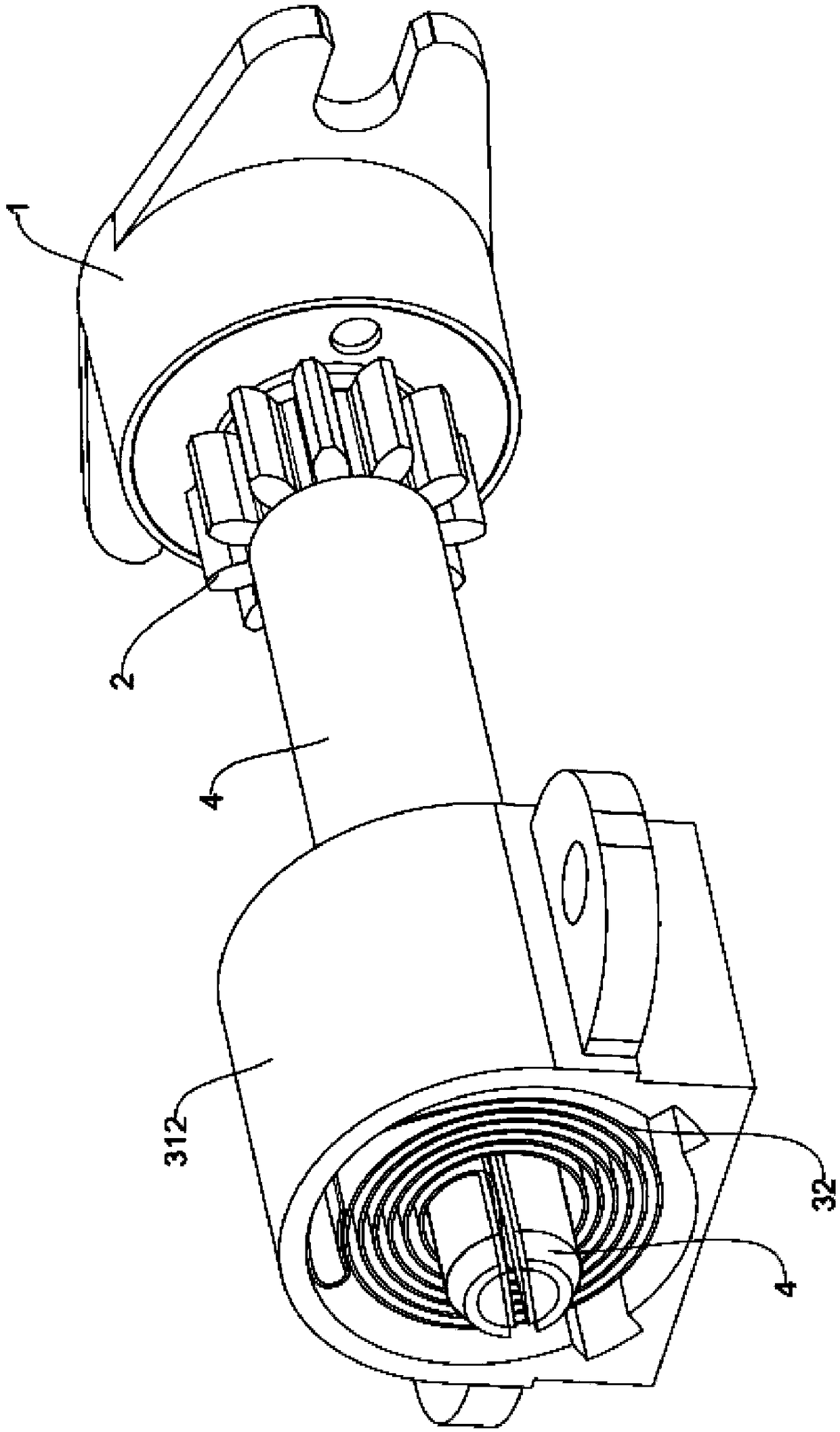

[0044] like Figure 1-4 As shown, a transmission mechanism is provided in this embodiment, including a rotary damper 1, a rotating wheel 2, a transmission rod 4 and a spring assembly 3, wherein the transmission rod 4 is a cylindrical stepped shaft, and the transmission rod in this embodiment 4 is integrally formed with the output shaft of the rotary damper 1, and an integrally formed rotating shaft (the following rotating shaft is the same as the rotating shaft here) is used to replace the output shaft and transmission rod 4 in the existing rotary damper 1 . In addition, the transmission rod 4 and the output shaft of the rotary damper 1 can be arranged separately, and the transmission rod 4 and the output shaft are installed coaxially during assembly.

[0045] The rotary damper 1 is fixed on the washing machine, and the rotating wheel 2 is arranged on the rotating shaft, and its specific position is adjusted according to the position of the transmission structure engaged with ...

Embodiment 2

[0055] This embodiment also provides a transmission mechanism, the elastic component is arranged on the outer periphery of the damper, and the spring component 3 can make the drop box pop out.

[0056] The spring assembly 3 includes a second clockwork spring (not shown in the figure) and a second spring holder (not shown in the figure), wherein the second spring holder is fixed on the washing machine, and the second clockwork spring is arranged on the second clockwork spring. In the second spring fixing seat, two ends of the second clockwork spring are respectively connected to the shell of the rotary damper 1 and the washing machine, and the rotary damper 1 is located inside the second clockwork spring. At this time, it is no longer necessary to set the transmission rod, the rotating wheel 2 is fixedly installed on the shell of the rotary damper 1, the output shaft of the rotary damper 1 is fixed and does not rotate, and the rotating wheel 2 and the shell of the rotary damper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com