Novel brushless direct current motor PWM setting method

A brushed DC motor, a new type of technology, applied in the direction of torque ripple control, etc., can solve the problems that the technology has not been reported yet, and the research of off-phase PWM control technology is seldom, so as to achieve the effect of weakening the low-speed commutation torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

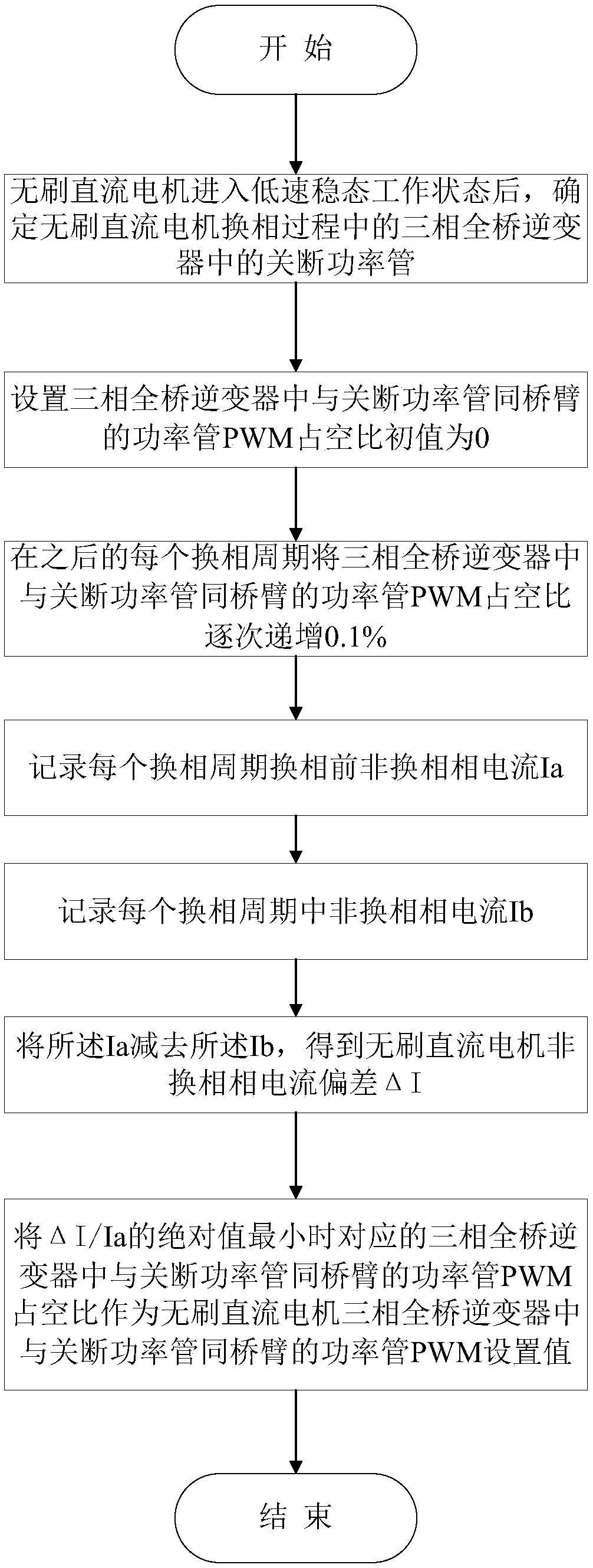

[0017] Such as figure 1 As shown, a novel brushless DC motor PWM setting method of the present invention comprises the following steps:

[0018] Step 1. Perform PWM modulation control on the brushless DC motor. After the brushless DC motor enters a low-speed steady-state working state, determine to turn off the power tube in the three-phase full-bridge inverter during the commutation process of the brushless DC motor;

[0019] Step 2, setting the PWM duty cycle initial value of the power tube of the same bridge arm as the shut-off power tube in the three-phase full-bridge inverter to 0;

[0020] Step 3. In each subsequent commutation period, the PWM duty cycle of the power tubes of the same bridge arm as the shut-off power tube in the three-phase full-bridge inverter is gradually increased by 0.1%;

[0021] Step 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com