Slab-beam column seismic-isolation connection device

A connecting device, beam-column technology, applied in the direction of anti-seismic, floor, building components, etc., can solve the problems of poor anti-seismic performance of fully prefabricated floors, achieve the effect of anti-seismic performance, reduce earthquake force, and save social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

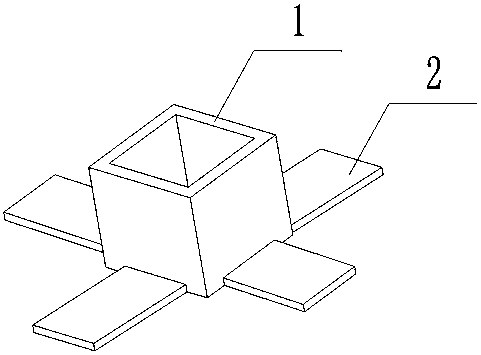

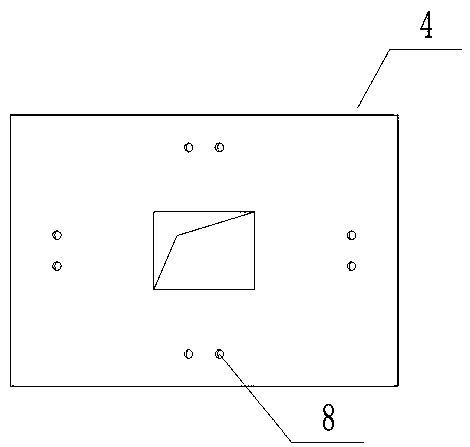

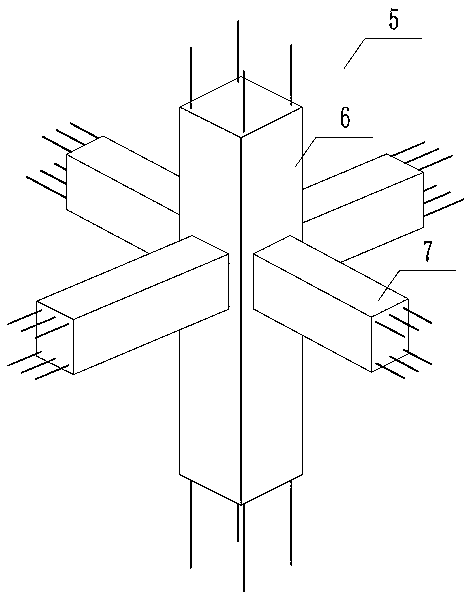

[0020] 1. A plate-beam-column vibration isolation (vibration) connection device, comprising a plate-column isolation member 1 and a plate-beam cushion layer 2. The inner and outer sides of the plate-column isolation member 1 are square in cross section and are arranged in different directions Four slab-beam cushions 2, in which the inner side of the slab-column isolation member 1 is consistent with the cross-section of the column unit 6, and the outside is consistent with the holes of the prefabricated floor unit 4, and the slab-beam cushion 2 is in the slab-column isolation member 1 in the column unit 6. After being installed in place, it just touches the top surface of the corresponding beam unit 7. The width of the plate-beam cushion 2 is greater than the width of the top surface of the beam unit 7 (such as figure 1 , figure 2 , image 3 ). The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com