Self-breaking type pressing bolt assembly

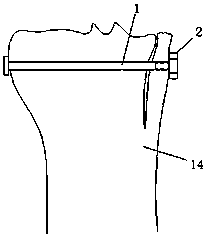

A bolt assembly, self-disconnecting technology, applied in the direction of fastening devices, internal fixators, internal bone synthesis, etc., to achieve good promotion and use, avoid complications, and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

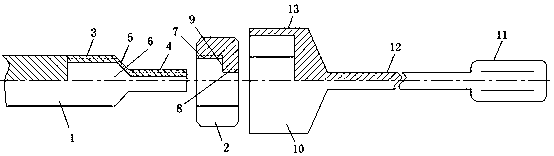

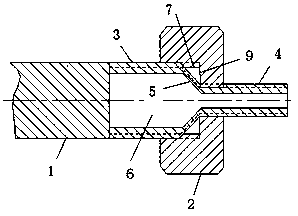

[0015] The self-breaking pressure bolt assembly of the present invention is composed of a pressure bolt 1 , a pressure nut 2 and a twist screwdriver 10 .

[0016] figure 1 , 2 It shows that the screw rod of the pressurizing bolt 1 is an unequal diameter screw rod, the diameter of the rear part of the screw rod is smaller than the diameter of the front part of the screw rod, and the junction of the large diameter section 3 and the small diameter section 4 of the screw rod is an inclined annular connecting section 5, the screw rod The small-diameter section 4, the annular connecting section 5 and the large-diameter section 3 close to the annular connecting section 5 are respectively threaded for screwing in the pressurized nut 2.

[0017] figure 1 , 2 It shows that there is an inner hole 6 in the rear part of the screw of the pressure bolt 1, and the inner hole 6 extends from the end surface of the screw to the annular connecting section 5 beyond the junction of the large-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com