Bucket rod rocker arm mechanism of excavator

A rocker arm mechanism and excavator technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., and can solve the problem of long strokes of stick cylinders, affecting excavation speed, and stick running time Long and other problems, to achieve the effect of reducing hydraulic oil pressure and speeding up excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

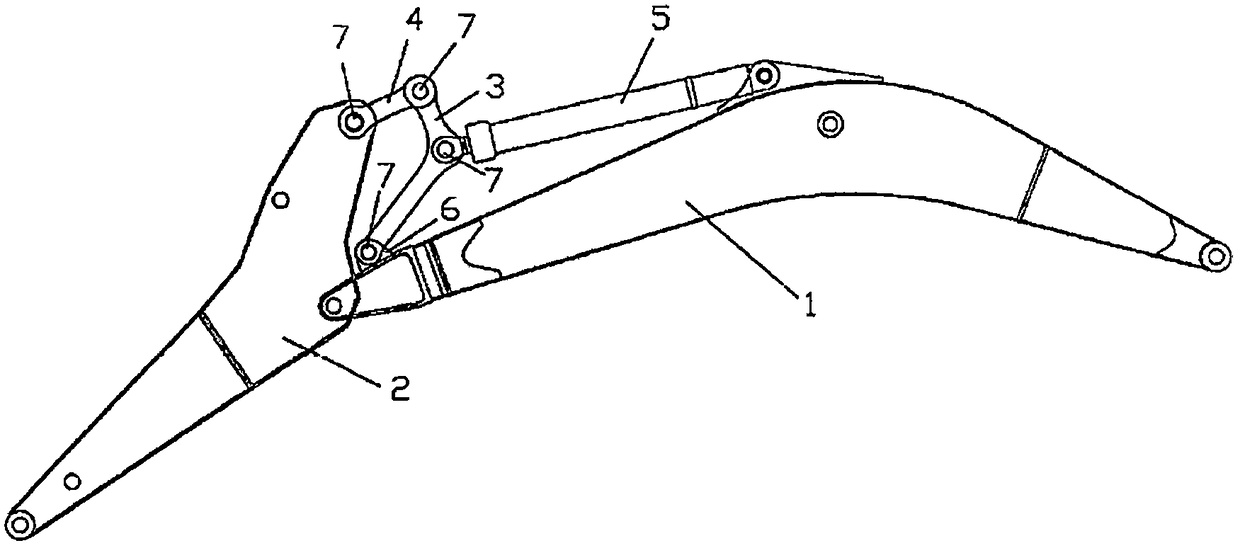

[0014] Such as figure 1 As shown, the second shaft hole on the top of the bucket 2 is hinged to the front shaft hole of the excavator arm 1, and the power arm of the bucket is between the upper end of the bucket 2 and the hinge point. A stick oil cylinder 5 is provided for driving the stick 2 to rotate relative to the excavator arm 1, which is the prior art. There are rocker swing rod 3 and stick push rod 4. There are three working shaft holes on the rocker swing rod respectively. The three working shaft holes are arranged in a triangle shape. The first working shaft hole of rocker swing rod 3 passes through the The rocker bearing seat 6 at the front end of the swing arm 1 is hinged with the excavator power arm front, and the rocker bearing seat is located on the top surface, side or bottom surface of the excavator arm front end. In this embodiment, the hinge point is located on the top surface of the front part of the power arm of the excavator. The third working shaft hole...

Embodiment 2

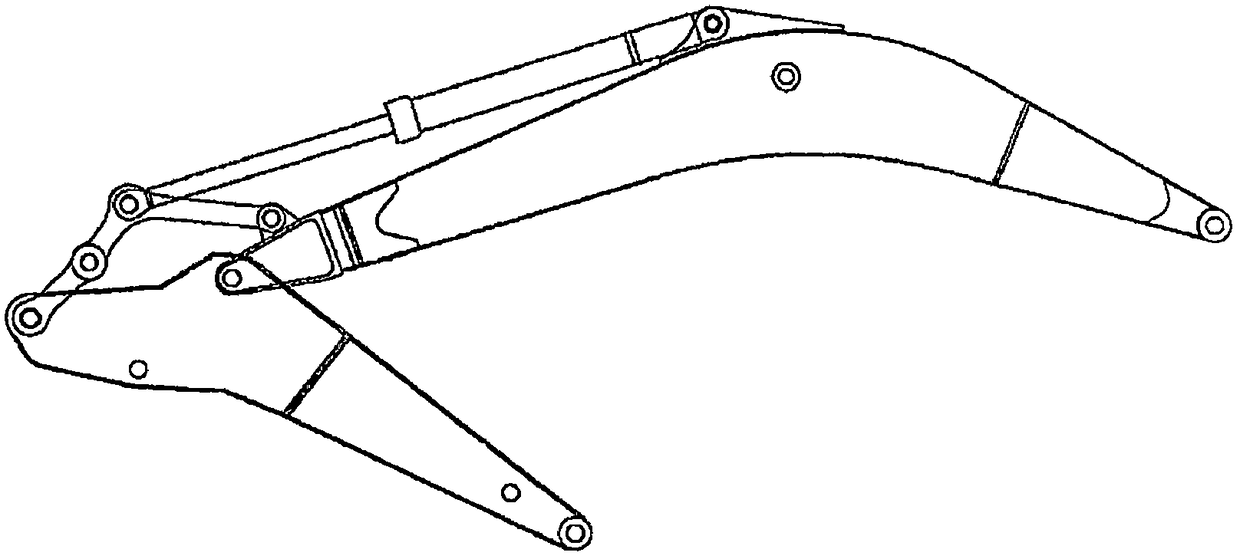

[0017] The difference between the second embodiment and the first embodiment is that the swing arm of the rocker is arc-shaped, and the rest of the structure and working principle are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com