A Fluid Reversing System Based on Hydraulic Pulse Control

A reversing system and hydraulic pulse technology, applied in the hydraulic field, can solve problems such as troublesome operation, mechanical failure, unsuitable electric switch, etc., and achieve the effects of convenient operation, wide application range and novel control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

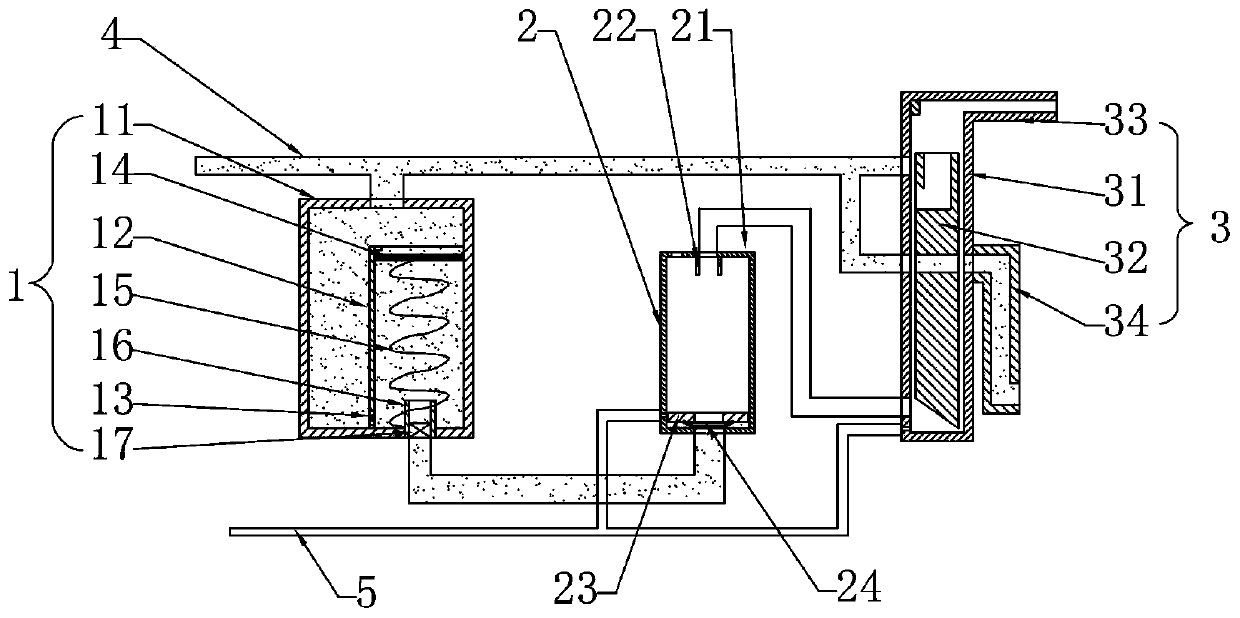

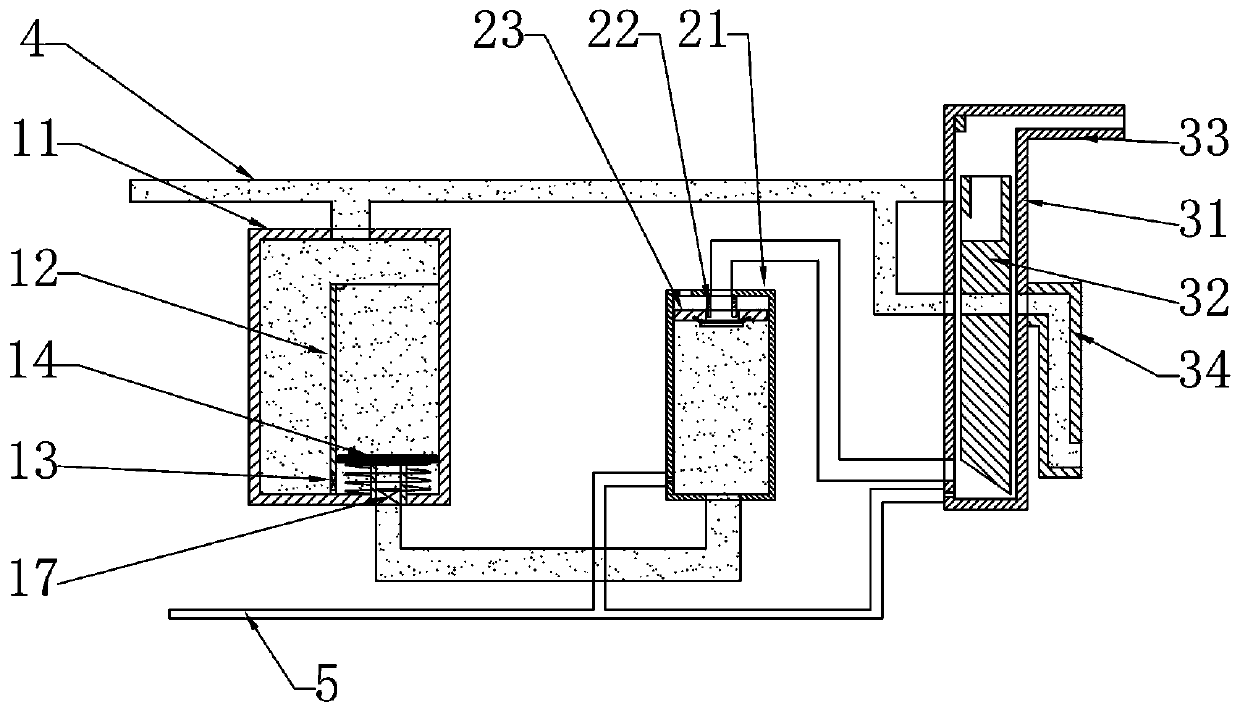

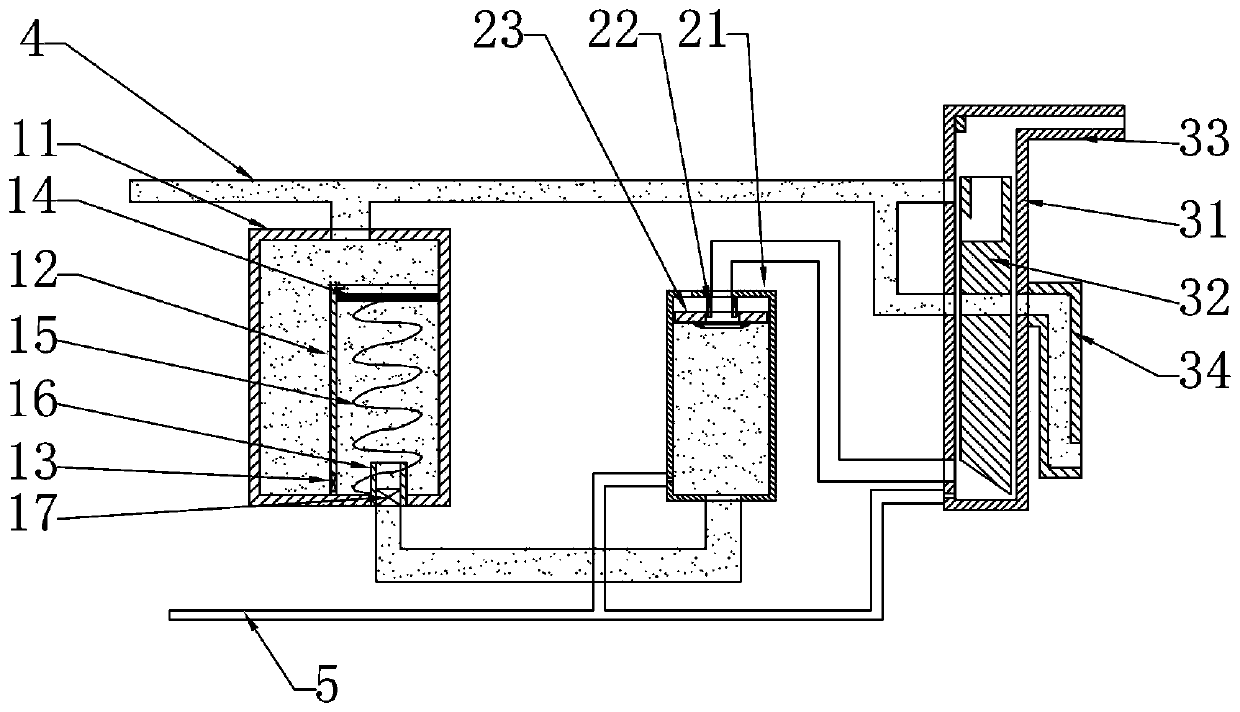

[0049] Such as figure 1 As shown, a fluid reversing system based on hydraulic pulse control in this embodiment includes a drive chamber 1 , a transfer chamber 2 , a reversing assembly 3 , an input pipe 4 and a return pipe 5 .

[0050]Such as figure 1 , Figure 5 As shown, the driving chamber 1 includes a main tank body 11 , an auxiliary tank body 12 , an inner one-way valve 13 , a push plate 14 , a return spring 15 , a receiving cylinder 16 and an outer one-way valve 17 .

[0051] The main tank body 11 is a cylindrical shell, and the top surface and the bottom surface of the main tank body 11 respectively have a through hole.

[0052] The auxiliary tank body 12 is a cylindrical thin-walled member, the auxiliary tank body 12 is located in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com