Cross girder structure integrated loading system

A technology of structural synthesis and loading system, which is applied in measurement devices, instruments, scientific instruments, etc., and can solve the problem of inability to simulate the working conditions of multiple loads at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

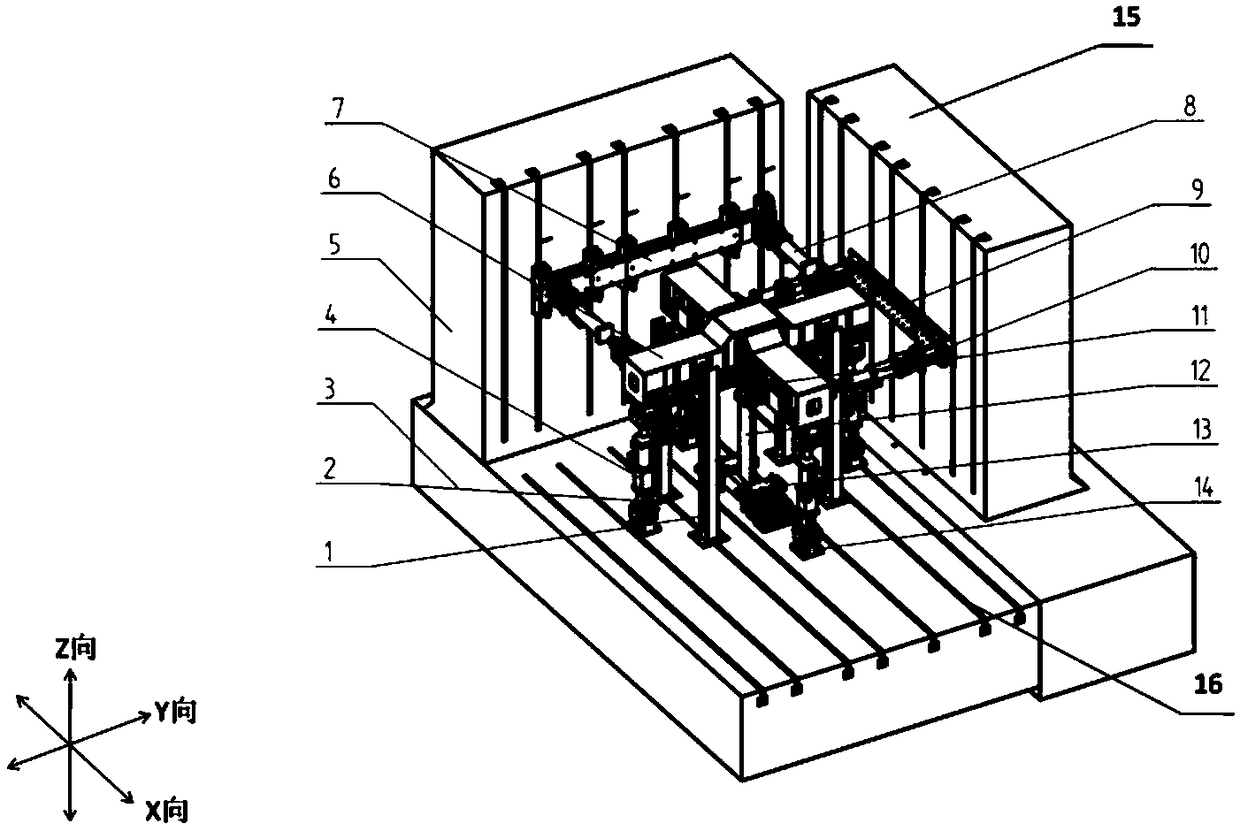

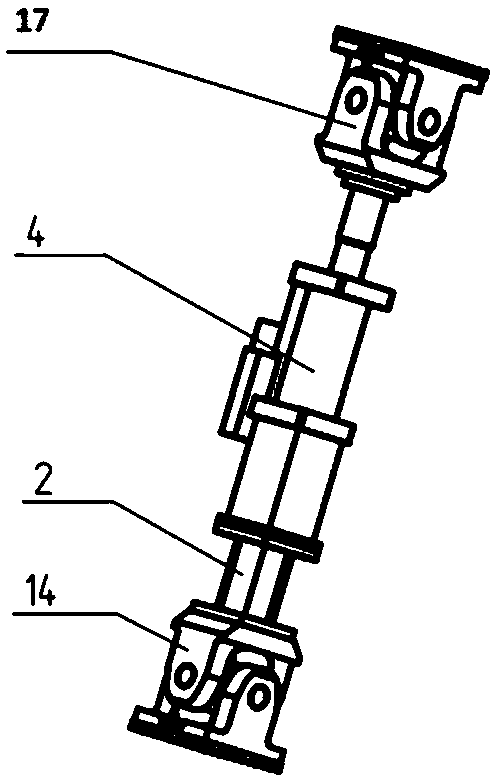

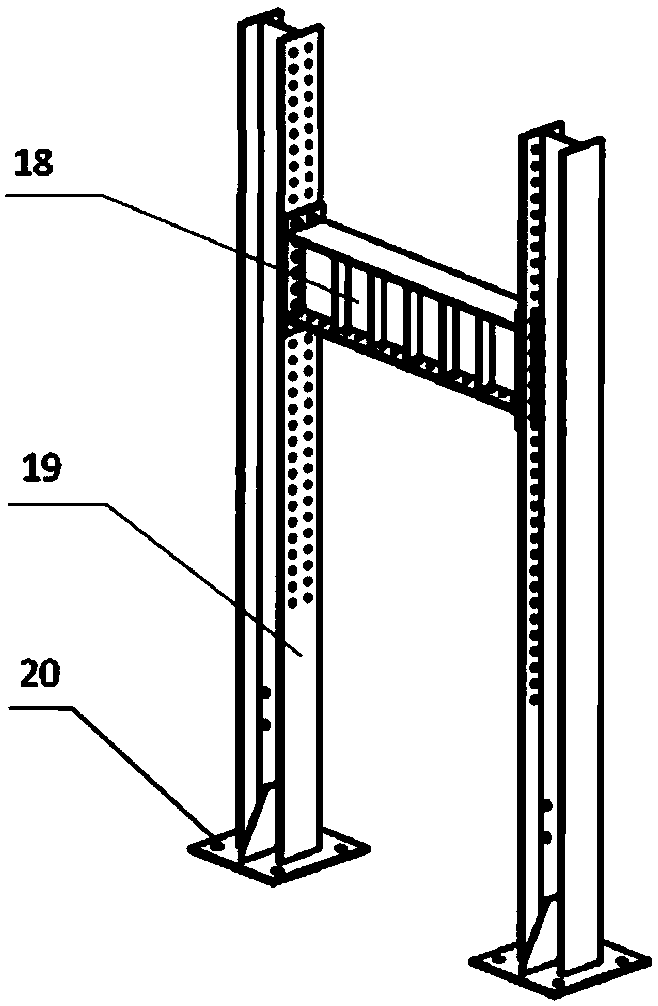

[0040] Such as figure 1 As shown, the comprehensive loading system of the cross main beam structure of the present embodiment includes: reaction force platform 3, X direction reaction force wall 15, Y direction reaction force wall 5, cross main beam 6, tooling accessories, four Z direction Actuator 4, two X-direction actuators 8, two Y-direction actuators 10, X-direction actuator mount 7, Y-direction actuator mount 9, support structure 1, etc.

[0041] Wherein, the reaction force platform 3 is placed on a horizontal plane. The reaction platform 3 , the X-direction reaction wall 15 and the Y-direction reaction wall 5 are arranged perpendicular to each other. In this embodiment, there is no special limitation on the structures of the reaction wall and the reaction platform. For example, the two kinds of reaction walls 5 and 15 can be either civil structures or steel frame structures. The reaction force platform 3 can be either a civil structure or a steel frame structure.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap