A detachable adjustable truss clamping and positioning device and positioning method

A detachable and pressing device technology, which is applied to home appliances, other home appliances, household components, etc., can solve the problems of long truss axis axis deviation, etc., to reduce the long truss axis deviation, improve assembly coordination accuracy, and optimize positioning The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

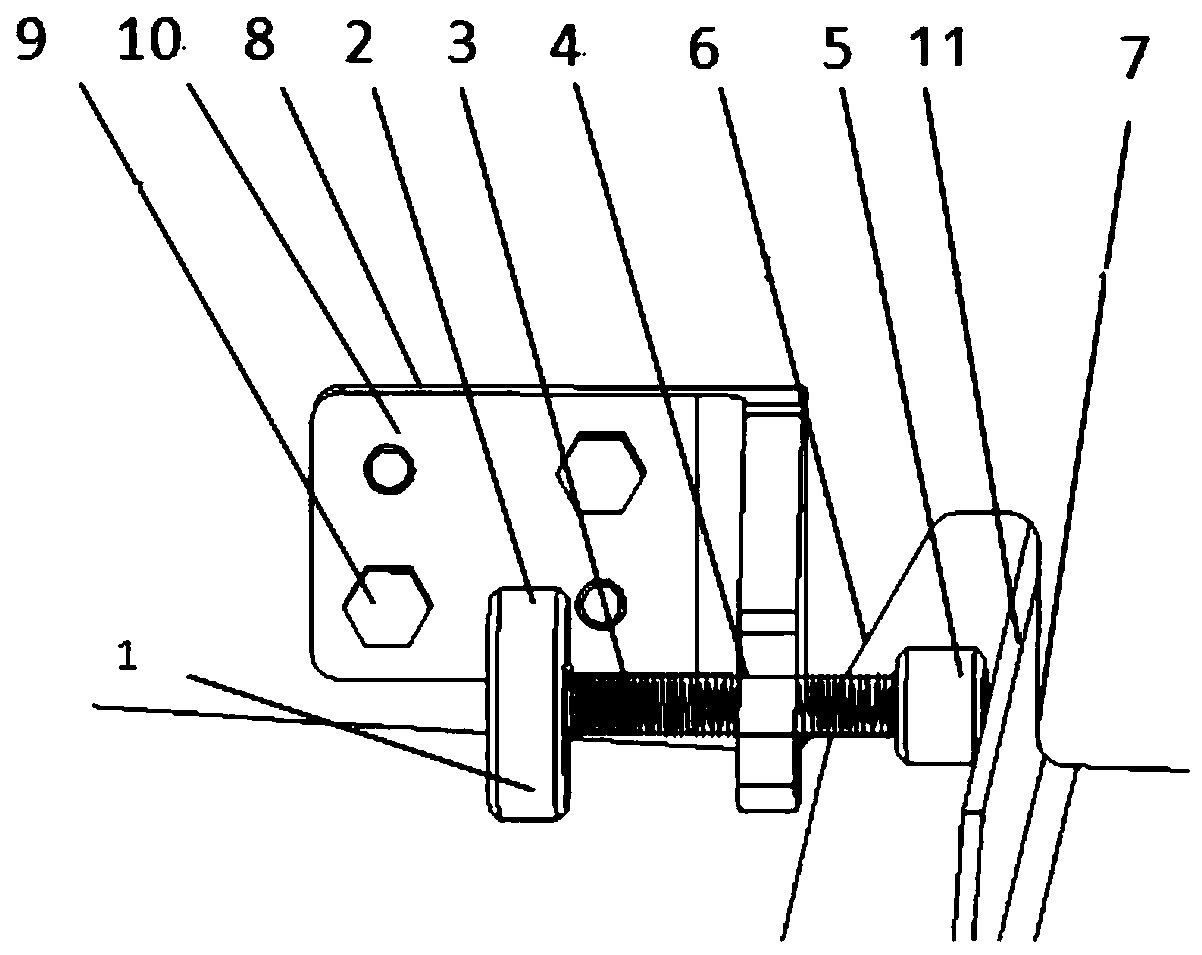

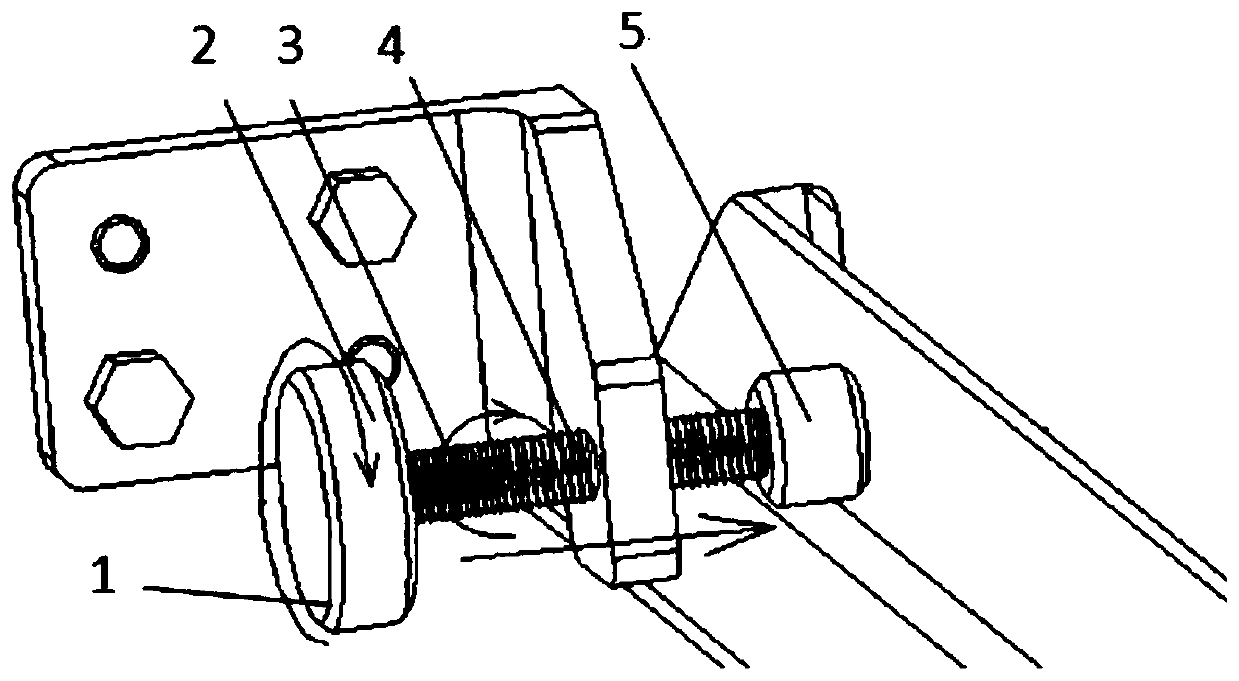

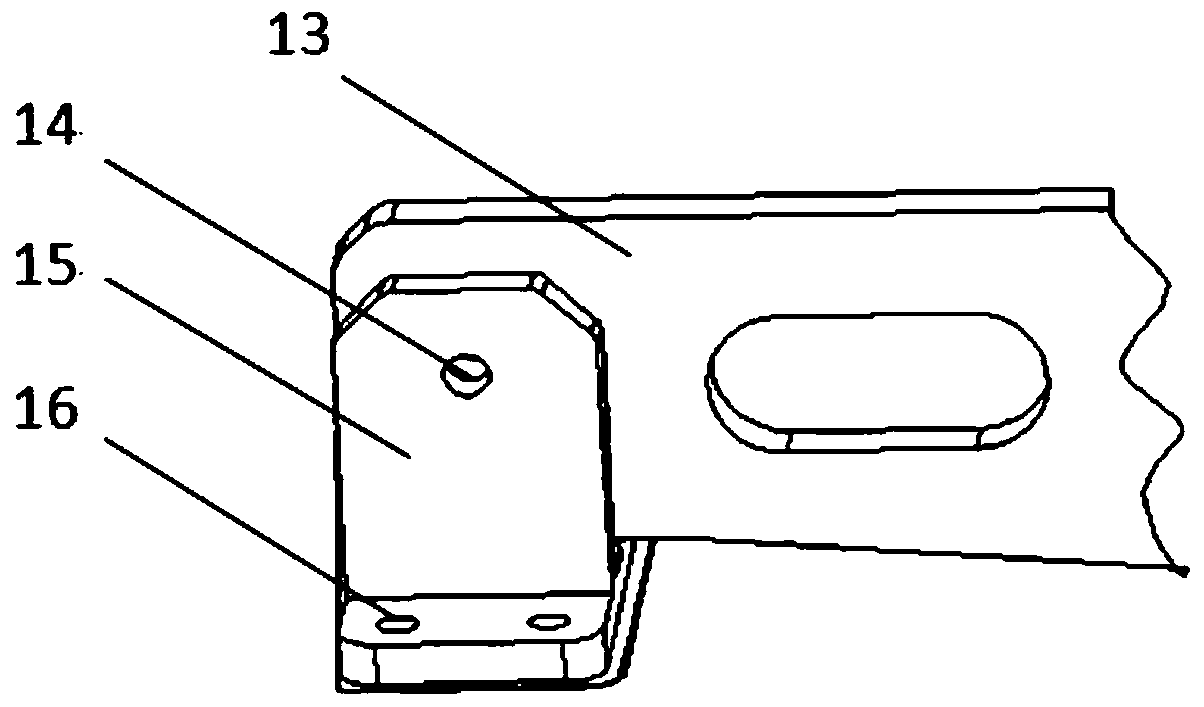

[0017] Such as figure 1 As shown in -4, a detachable adjustable long truss clamping and positioning device includes a positioning and pressing device 1, an angle seat 8, a positioning clamp 13 and a support 15, and the positioning and pressing device 1 includes a rotary wheel 2, which is connected with a rotary The lead screw 3 connected to the wheel, and the smooth pressing block 5 made of buffer material fixed on the other end of the lead screw 3, the lead screw 3 is matched with the limit hole 4 on the corner seat 8, and the positioning and pressing device 1 is connected with the The corner seat 8 is connected, and the corner seat 8 is connected with the positioning clamp plate 13. The positioning clamp plate 13 has a plurality of long stringer gaps 6, and one side of the gap is the positioning reference plane 7. The positioning clamp plate 13 is detachably connected with the support, and the support Seat is fixed on the profile plate 17 of stringer.

[0018] When performi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com