Heteromorphic copper bar

A special-shaped and current technology, applied in the direction of conductors, contact parts, fixed/insulated contact components, etc., can solve the problem of large installation space and achieve the effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

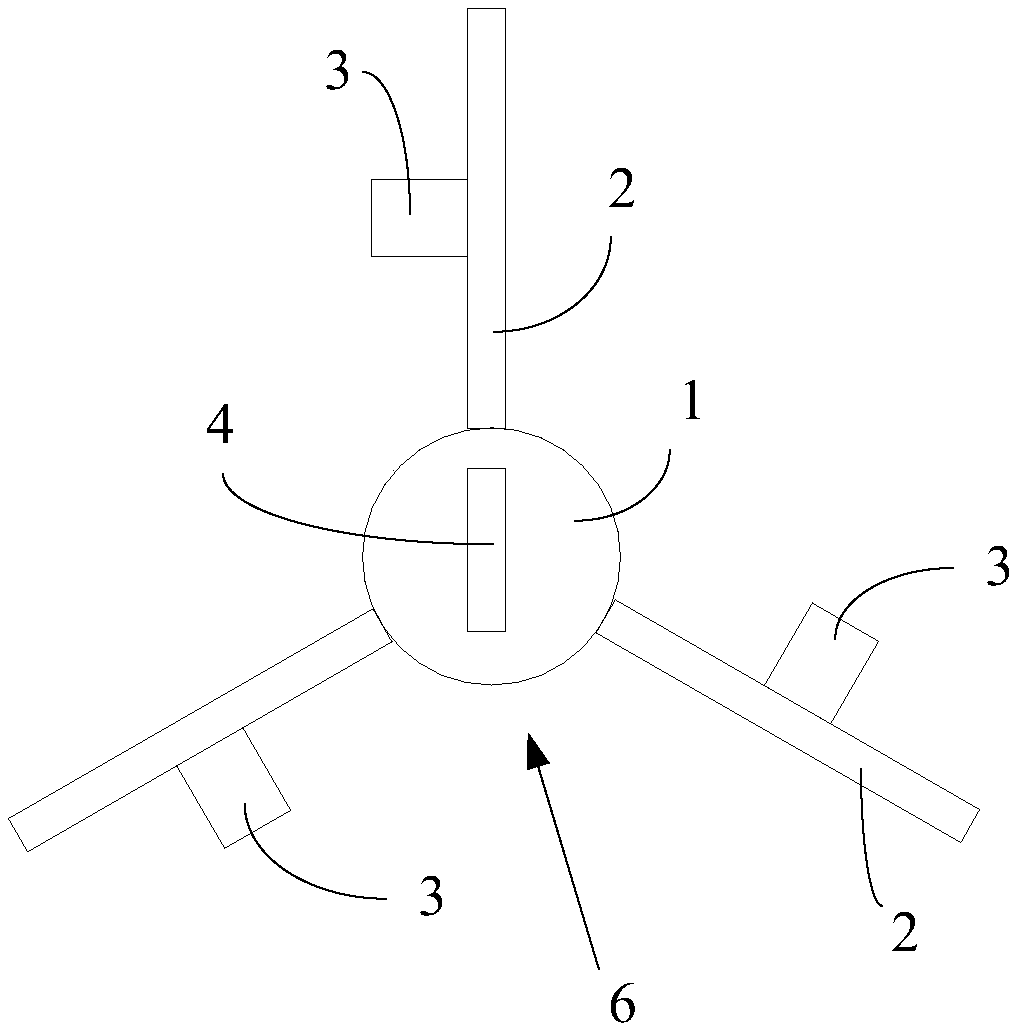

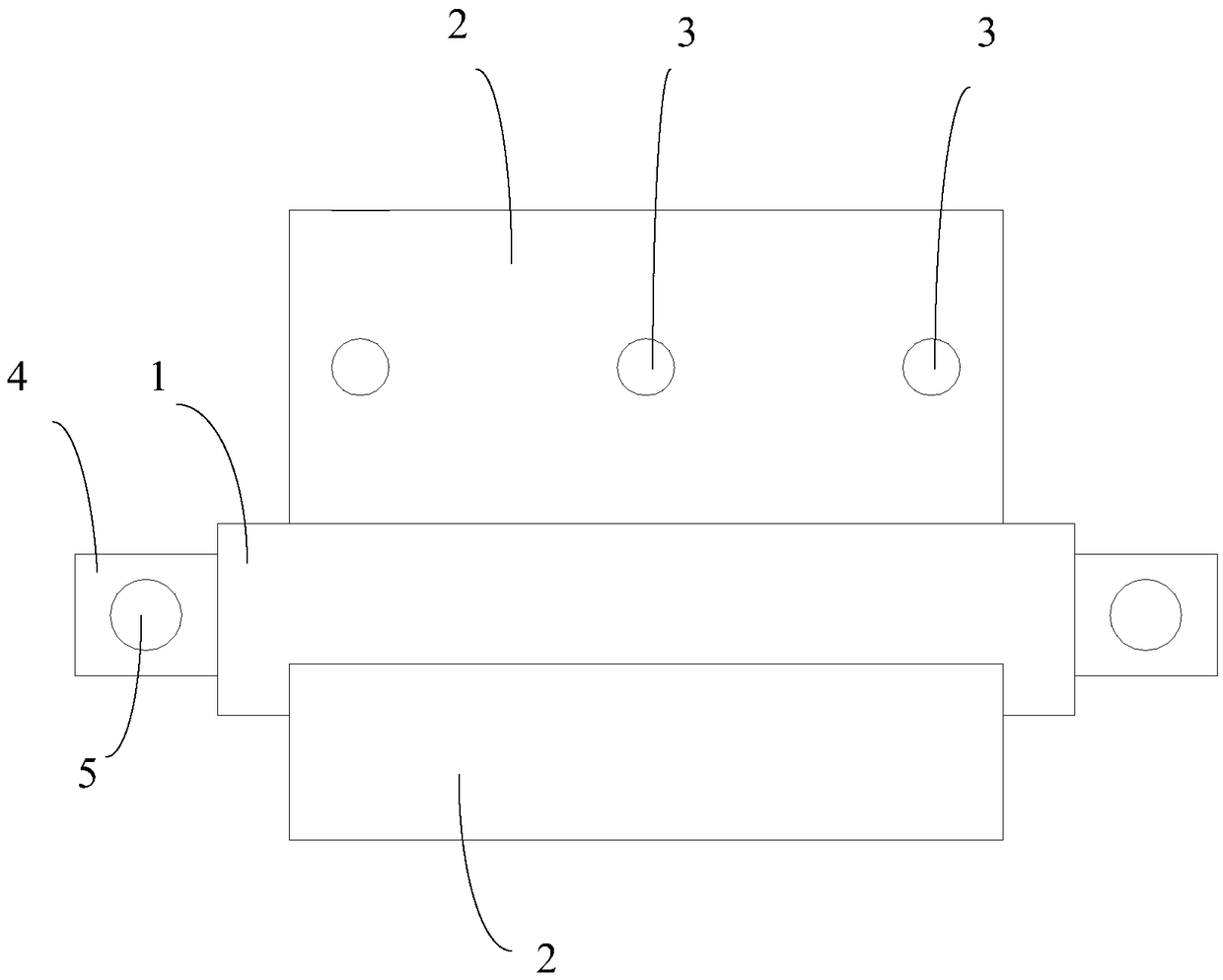

[0023] The embodiment of the present invention provides a special-shaped copper bar, such as figure 1 As shown, the special-shaped copper bar is suitable for the conduction of three-phase alternating current. The special-shaped copper bar includes a fixed shaft 1 and three current carrying plates 2. The fixed shaft 1 is made of insulating material, and each current carrying plate 2 uses the central axis of the fixed shaft 1 The shaft is circumferentially fixed on the outer peripheral wall of the fixed shaft 1 , and the angles between every two adjacent current carrying plates 2 are equal, and each current carrying plate 2 is provided with a plurality of terminal posts 3 .

[0024] In the special-shaped copper bar provided by the embodi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap