Temperature-variable isothermal shift reactor

An isothermal transformation and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as strict equipment requirements, reduced heat transfer coefficient of heat exchange tubes, increased pressure of steam drums and heat exchange tubes, etc. , to avoid difficult control, reduce equipment investment, and achieve the effect of constant yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

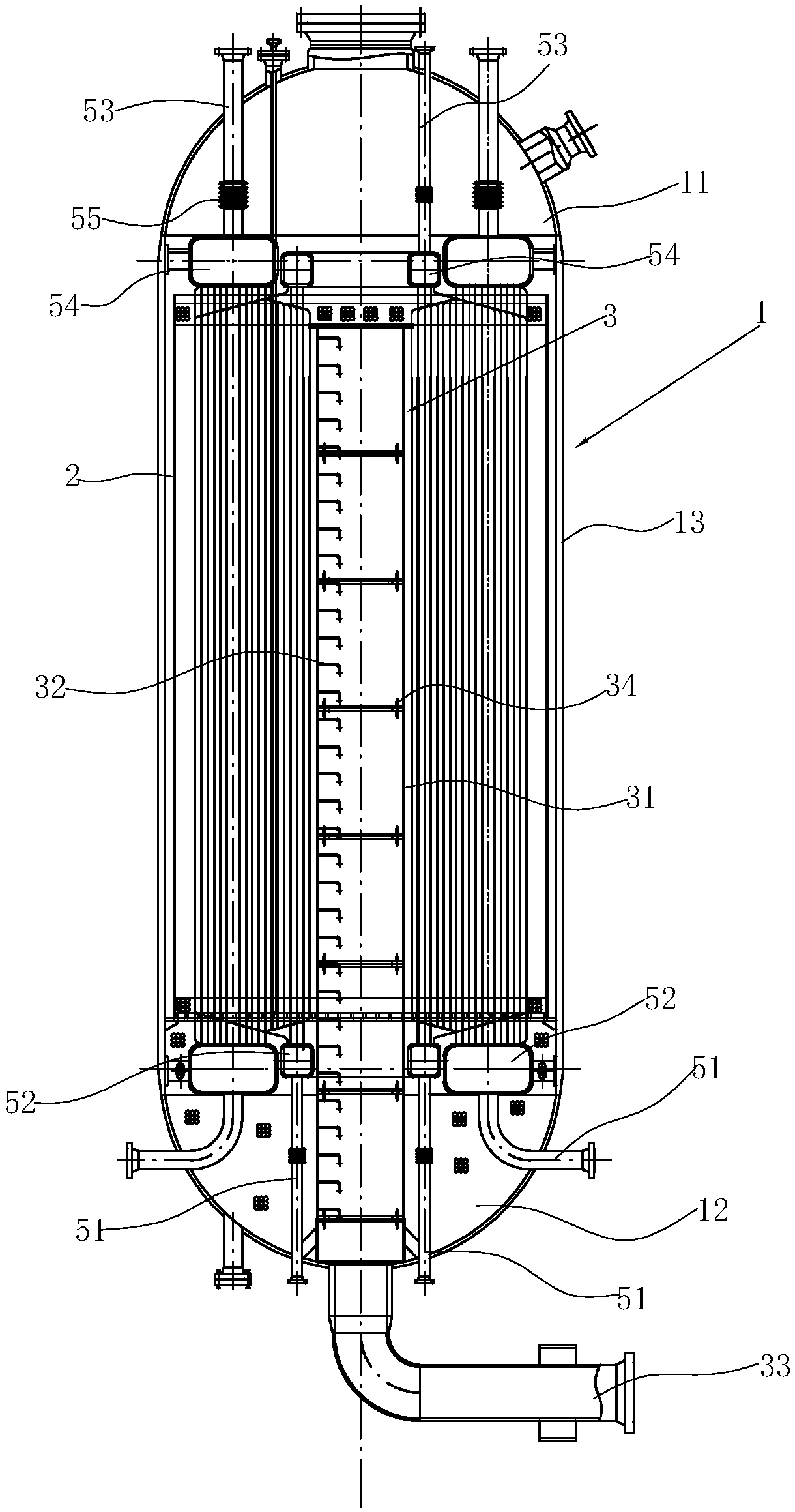

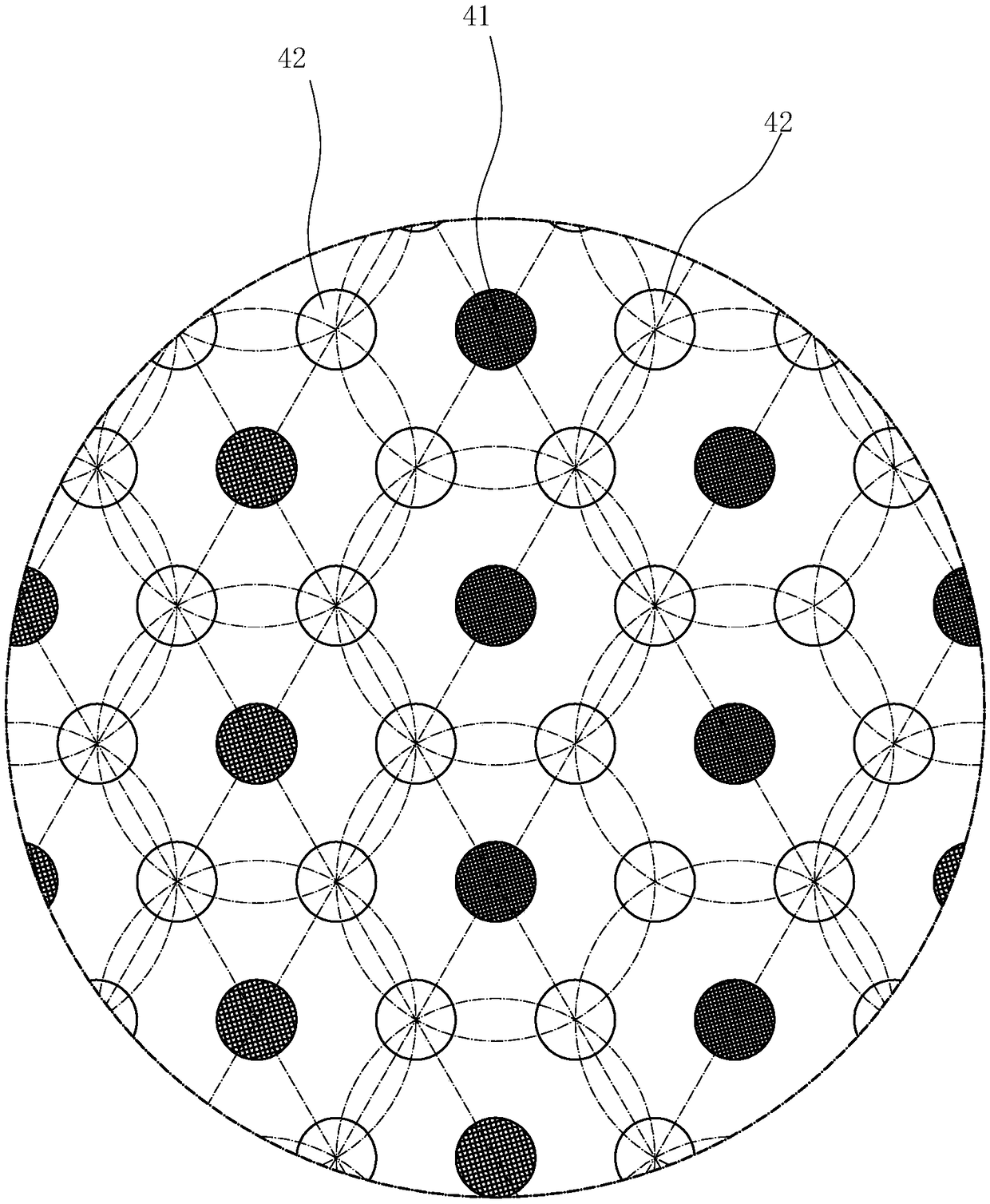

[0027] Such as Figure 1 to Figure 3 Shown, this variable temperature isothermal shift reactor comprises:

[0028] The furnace body 1 is a conventional structure, including an upper head 11 , a lower head 12 and a cylinder 13 connected between the upper head 11 and the lower head 12 .

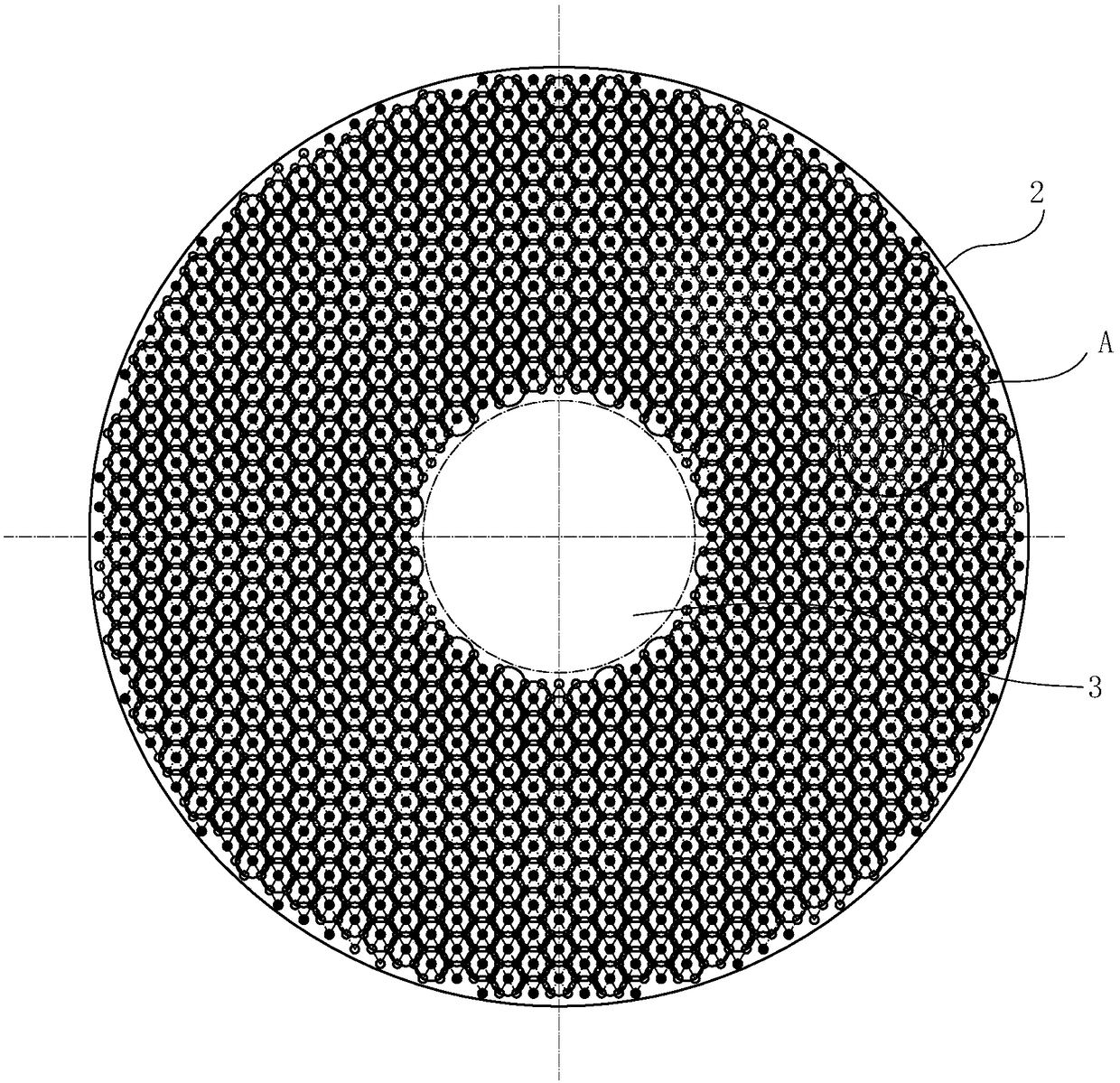

[0029] The catalyst frame 2 is used for loading catalyst and is arranged in the cylinder body 13 . The catalyst frame 2 can be any one of the prior art according to the needs, for example, it can be an axial reactor, it can also be a radial reactor, or it can also be an axial radial reactor, which can be set according to the needs. This embodiment is a radial reactor, and the feed gas enters the catalyst frame from the side wall of the catalyst frame 2 .

[0030] The synthesis gas collection pipe 3 is used to collect the synthesis gas and send the synthesis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com