Multi-nozzle solid attitude control engine blocking cover structure

An engine and multi-nozzle technology, applied in the direction of machine/engine, rocket engine device, mechanical equipment, etc., can solve the problems of increased design cost, small geometric size of nozzle, excessive ignition pressure peak, etc., to save cost and reduce test. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

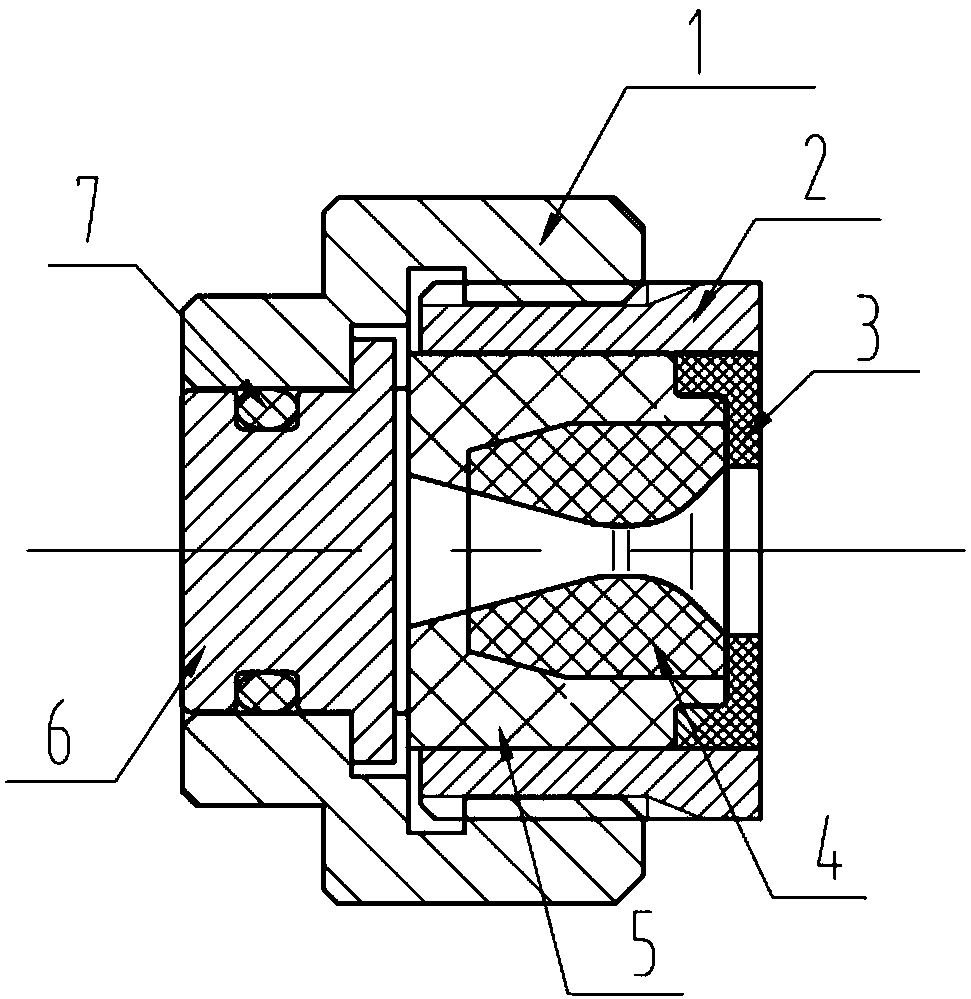

[0023] Such as figure 1 As shown, the present invention provides a multi-nozzle solid attitude control engine plugging structure, including nozzle snap ring 1, piston 6 and sealing ring 7, wherein,

[0024] The piston 6 is fixed on the outlet section of the diffuser section of the nozzle housing 2 in the nozzle assembly through the nozzle snap ring 1 , and the nozzle snap ring 2 and the piston 6 are sealed by a sealing ring 7 .

[0025] Here, after the engine is ignited, the piston and the combustion chamber form a closed cavity, the pressure in the combustion chamber rises, the charge is ignited, the pressure in the combustion chamber exceeds the allowable pressure of the piston, the piston is blown out, and the nozzle cap is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com