Use method of truss type sprinkler wagon

A sprinkler truck, truss-type technology, applied in the fields of botanical equipment and methods, application, gardening, etc., can solve the problems of large traction, power consumption, crop rolling, and increased weight of the sprinkler truck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

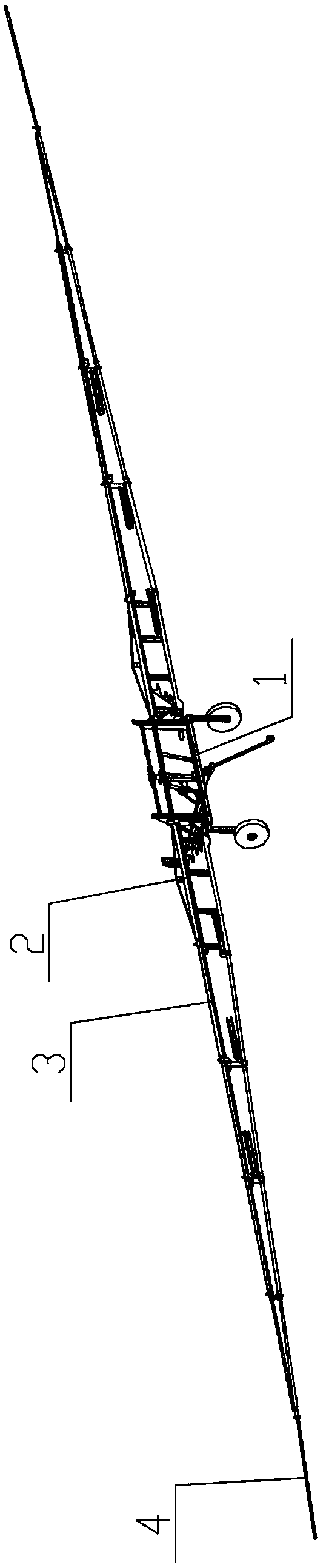

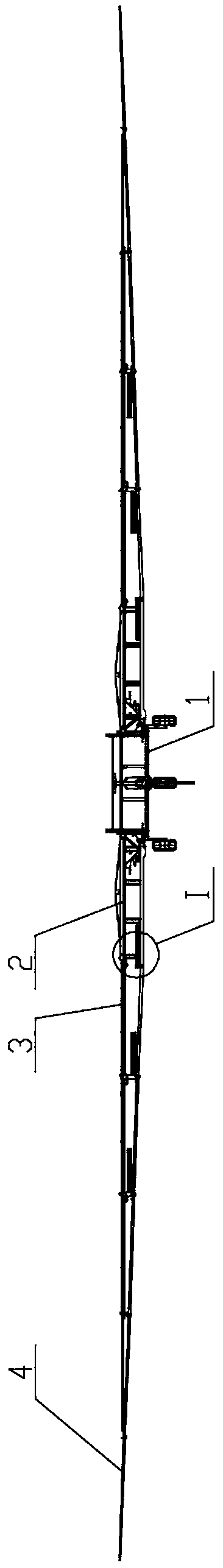

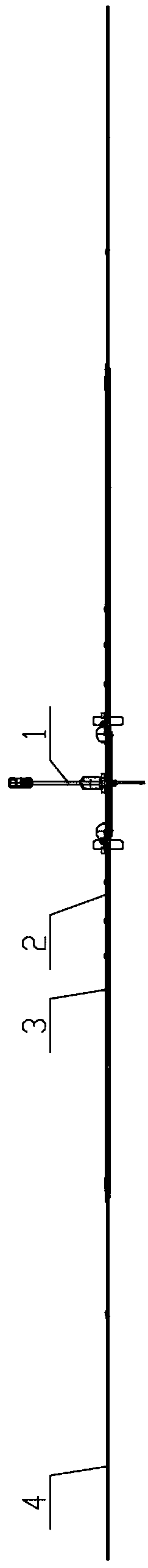

[0040] The present invention will be further described below in conjunction with the accompanying drawings (the truss-type sprinkler vehicle is described below with the pulling-out direction of the truss-type sprinkler car as the front, the direction in which the telescopic truss section 3 extends is the outer direction, and the direction in which the telescopic truss section 3 is retracted is The inside direction is described).

[0041] Such as Figure 1 to Figure 8 As shown, the truss-type sprinkler vehicle includes a main supporting underframe 1 and a swing truss.

[0042] The bottom of the main supporting base frame 1 is provided with supporting wheels 11 including supporting wheel frames.

[0043] The swing truss includes a left truss, a middle truss, and a right truss. The middle truss is fixedly installed on the main supporting frame 1, the middle truss is provided with sprinkler irrigation water input main pipeline, and the left and right truss are symmetrically arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com