Joint strip tool for costume designing

A clothing design and stripping technology, which is applied in the field of clothing design, can solve problems such as uneven width, uneven sewing of strips, and high requirements for sewing skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

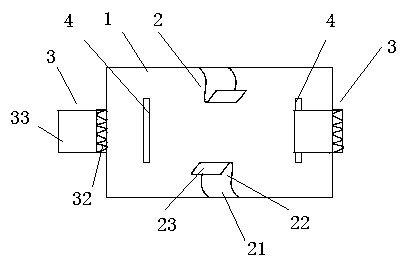

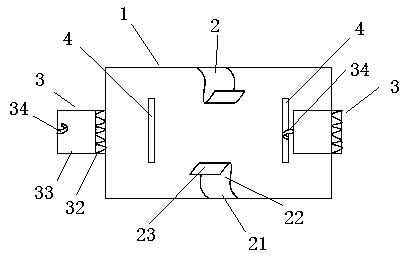

[0022] The mounting plate (not shown in the figure) of the folding pressing plate 3 is connected to the folding plate 33 with a common rotation shaft, and the elastic member 32 such as a spring is sheathed on the rotation shaft. The elastic member does not need to be arranged on the rotating shaft too tightly, as long as it can provide enough force to press the sticker. If the pressing force is insufficient, magnetic adsorption particles can also be set on the area of the base plate 1 covered by the folded plate 33. The folded plate is made of metal. When the folded pressing plate is closed, the folded plate 33 can be adsorbed on the base plate 1. In another embodiment, felt is provided on the peripheral side of the suture groove 4, and an adhesive component is provided on the side of the folded plate 33 folded on the bottom plate 1. The adhesive component can be Velcro. When the folded plate is covered on the base plate, Sticky parts are bonded to the felt. When it's time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com