A method for preparing a chain-type wet-process black silicon cell with high conversion efficiency

A high-conversion, solar cell technology, applied in the field of solar cells, to achieve the effect of improving conversion efficiency, low recombination rate, and reducing recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A method for preparing a high-conversion-efficiency chain-type wet-process black silicon solar cell, comprising the following steps:

[0061] 1) Select P-type polycrystalline diamond wire silicon wafers, sequentially wash with organic alkali solution and water, and dry;

[0062] 2) Coating SiON:H film on the back and around the silicon wafer;

[0063] 3) Make a black silicon suede surface on the front side of the silicon wafer;

[0064] 4) Diffusion is performed on the front side of the silicon wafer to form a PN junction on the front side;

[0065] 5) Pickling with an acid solution to remove the phosphosilicate glass on the front of the silicon wafer and corroding the SiON:H film on the back and around the silicon wafer, then washing with water and drying;

[0066] 6) Anti-reflection film is coated on the black silicon suede surface, and no anti-reflection film is coated on the back of the silicon wafer;

[0067] 7) Print the positive electrode on the front side of ...

Embodiment 1

[0086] 1) Diamond wire polysilicon wafers use chain-type organic alkali cleaning equipment. The volume ratio of tetramethylammonium hydroxide to pure water is 1:15, and the cleaning time is 200s. cleaning process.

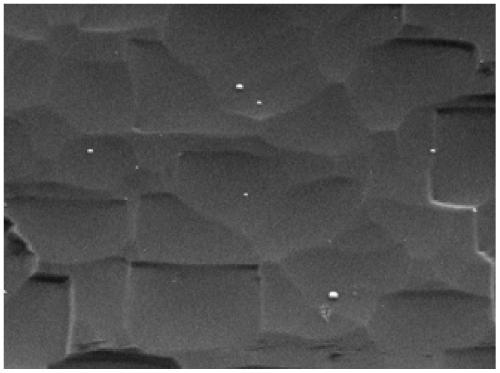

[0087] 2) The silicon wafer is inserted into the graphite boat carrier using tubular coating equipment. The back of the silicon wafer is coated with SiON:H film with a film thickness of 100nm and a refractive index of 1.85. Using silane flow rate of 500 sccm, ammonia gas flow rate of 5000 sccm, nitrous oxide gas flow rate of 7000 sccm and deposition pressure of 1500 mTorr, the total time for depositing SiON:H film on the back of the silicon wafer is 45 min.

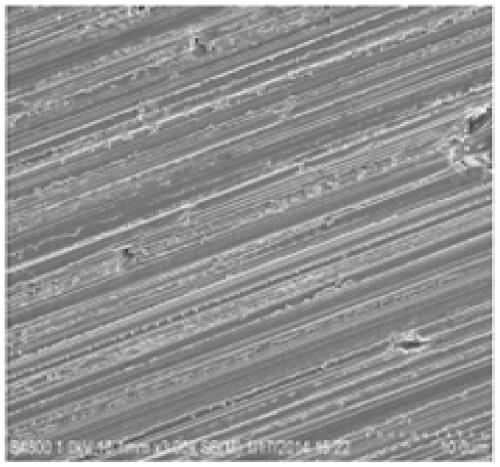

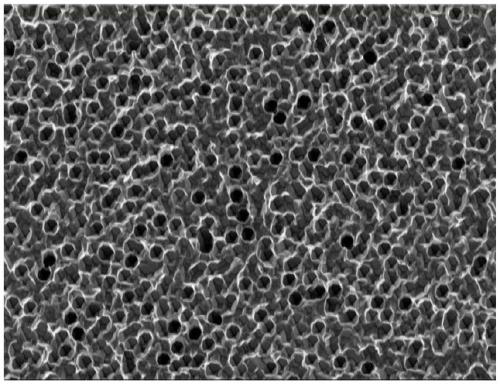

[0088] 3) Silicon wafer coated with SiON:H film enters chain-type wet black silicon equipment. The front side of the silicon wafer is made of black silicon suede. Suede surface, but the SiON:H film on the back of the silicon wafer reacts with the hydrofluoric acid solution in the wet black silicon equipment, ...

Embodiment 2

[0098] 1) Diamond wire polysilicon wafers use chain-type organic alkali cleaning equipment. The volume ratio of tetramethylammonium hydroxide to pure water is 1:5. The cleaning time is 200s. cleaning process.

[0099] 2) The silicon wafer is inserted into the graphite boat carrier using tubular coating equipment, and the back of the silicon wafer is coated with SiON:H film with a film thickness of 150nm and a refractive index of 2.0. Using silane flow rate of 700 sccm, ammonia gas flow rate of 3000 sccm, nitrous oxide gas flow rate of 4000 sccm and deposition pressure of 1500 mTorr, the total time for depositing SiON:H film on the back of the silicon wafer is 50 min.

[0100] 3) Silicon wafers coated with SiON:H film enter chain-type wet black silicon equipment. The front side of the silicon wafer is made of black silicon suede. The size of the suede is 800nm, and the reflectivity is 19%. Suede surface, but the SiON:H film on the back of the silicon wafer reacts with the hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com