Step-by-step type automatic reset mechanism

A technology of automatic reset and reset lever, which is applied in the direction of engine components, mechanical equipment, valve details, etc., can solve the problems of inability to reset, inability to effectively control multi-stage closing and opening and closing of the valve body, and affecting the next opening and closing of the valve, etc. , to achieve a precise and orderly reset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

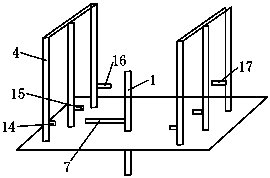

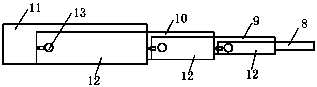

[0009] Combine below figure 1 with figure 2 Specific description embodiment:

[0010] The step-by-step automatic reset mechanism includes a bracket 4 and a graded switch bar 7. The graded switch bar includes a first-level switch bar 8, a second-level switch bar 9, a third-level switch bar 10 and a substrate 11. The first-level switch bar and the second-level switch bar The first-level switch bar is hingedly arranged, the second-level switch bar is hingedly arranged with the third-level switch bar, and the third-level switch bar is hingedly arranged with the base plate. Bar slot 12, the other side of the second-level switch bar, the third-level switch bar and the substrate are each provided with a reset hole 13, and the reset hole communicates with the bar slot; the support is provided with a reset lever corresponding to the reset hole 17. When the substrate is reset, the reset rod hits the third-level switch bar, the second-level switch bar and the first-level switch bar in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com