Potential Energy Luffing Energy Recovery Device for Construction Machinery Boom

An energy recovery device, boom potential energy technology, applied in fluid pressure actuation devices, mechanical equipment, earth movers/shovels, etc., can solve the problem of low energy recovery efficiency, low power generation and battery or capacitor charging efficiency, energy The problem of not being able to release and other problems can achieve the effect of realizing energy recovery and utilization, rapid energy recovery and utilization, and fewer energy conversion times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

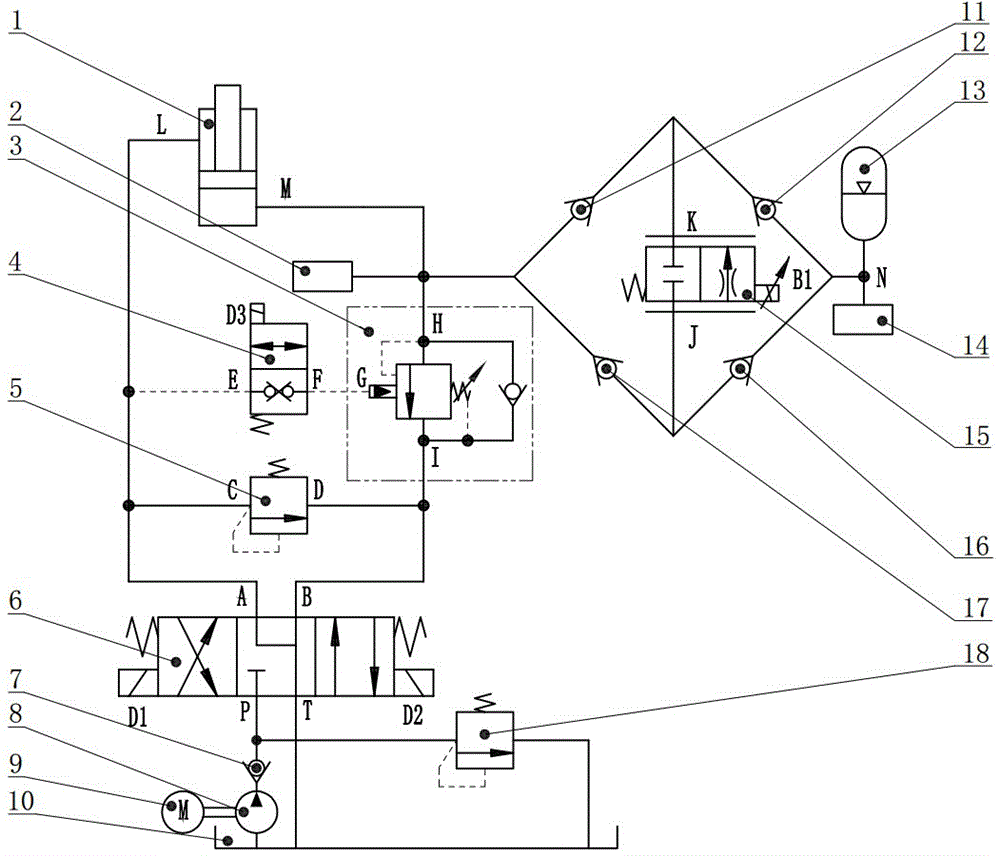

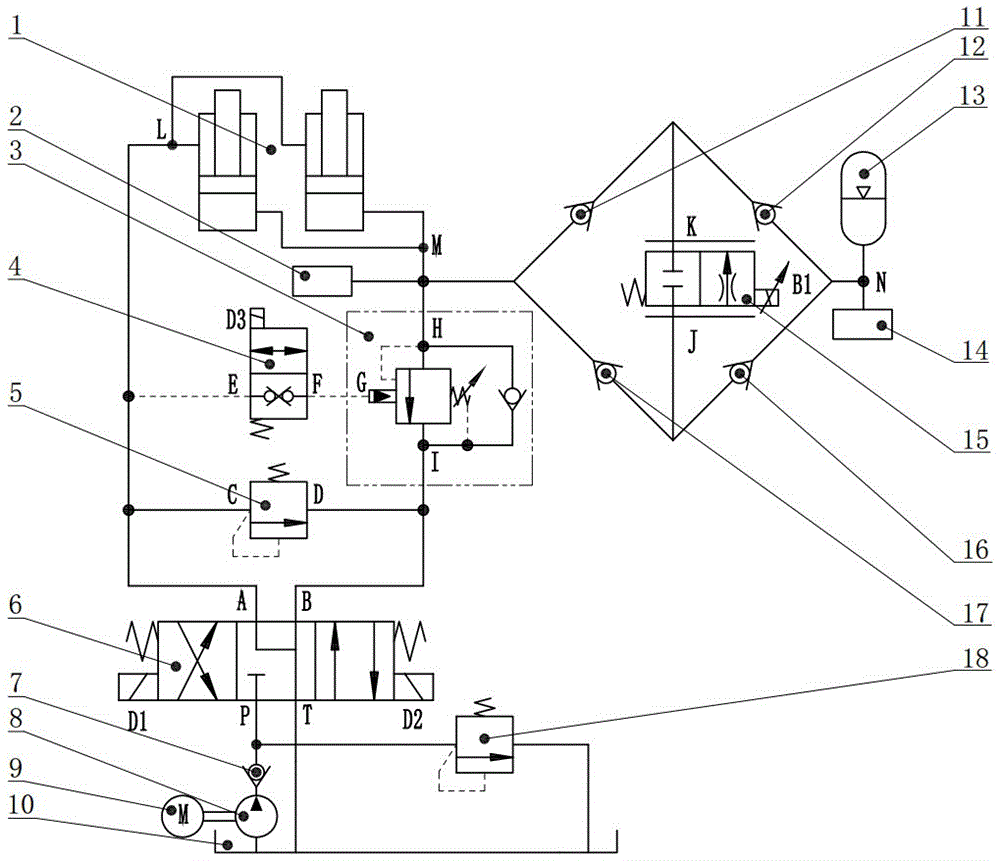

[0031] A kind of typical model of engineering machinery is excavator, and the technical scheme provided according to the present invention has designed figure 2 The shown excavator arm potential energy amplitude-changing energy recovery system is an example of the present invention, but this is not the only example implementing the technical solution of the present invention.

[0032] figure 2 The shown excavator boom potential energy luffing energy recovery system includes two boom cylinders, two pressure sensors, balance valves, two-position two-way solenoid valves, two overflow valves, three-position four-way electromagnetic reversing valves, five check valves, hydraulic pumps, electric motors, fuel tanks, accumulators, proportional flow valves and controllers.

[0033] Such as figure 2 As shown, two boom cylinders 1, first pressure sensor 2 and second pressure sensor 14, balance valve 3, two-position two-way solenoid valve 4, first relief valve 5 and second relief val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com