Clamp for tool holder

一种夹具、刀架的技术,应用在用于车床的刀具、刀夹的附件、铣刀等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

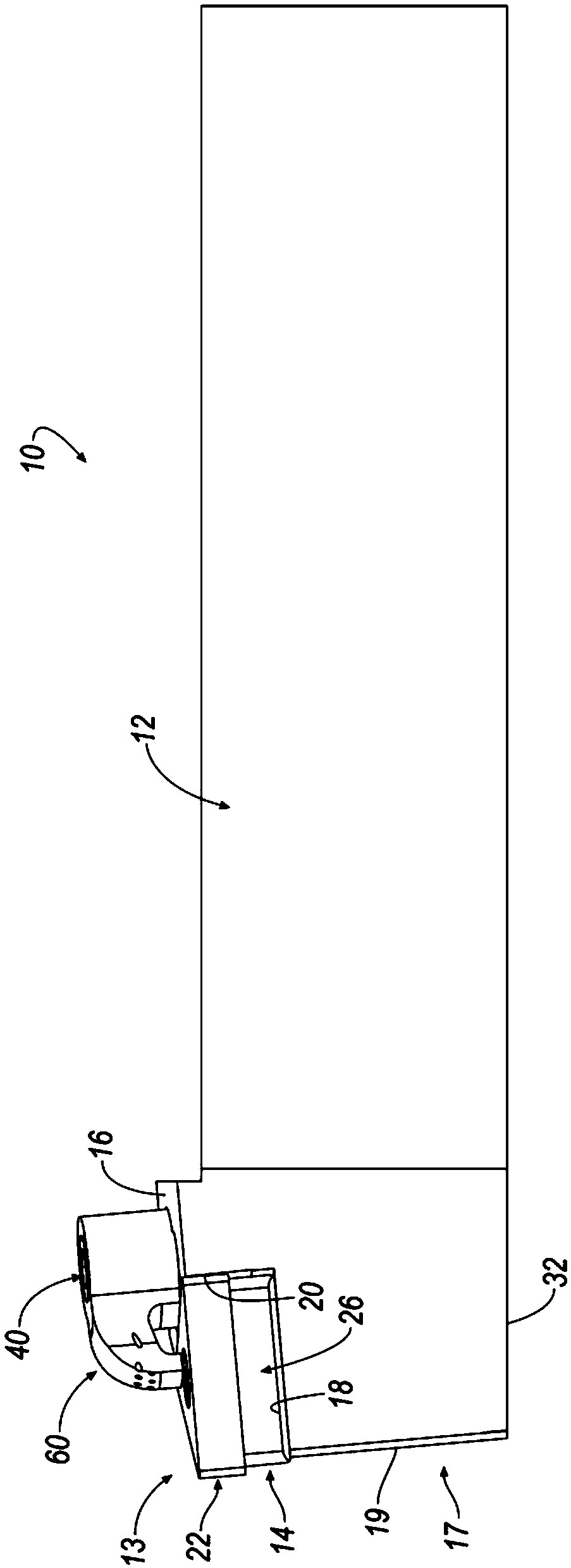

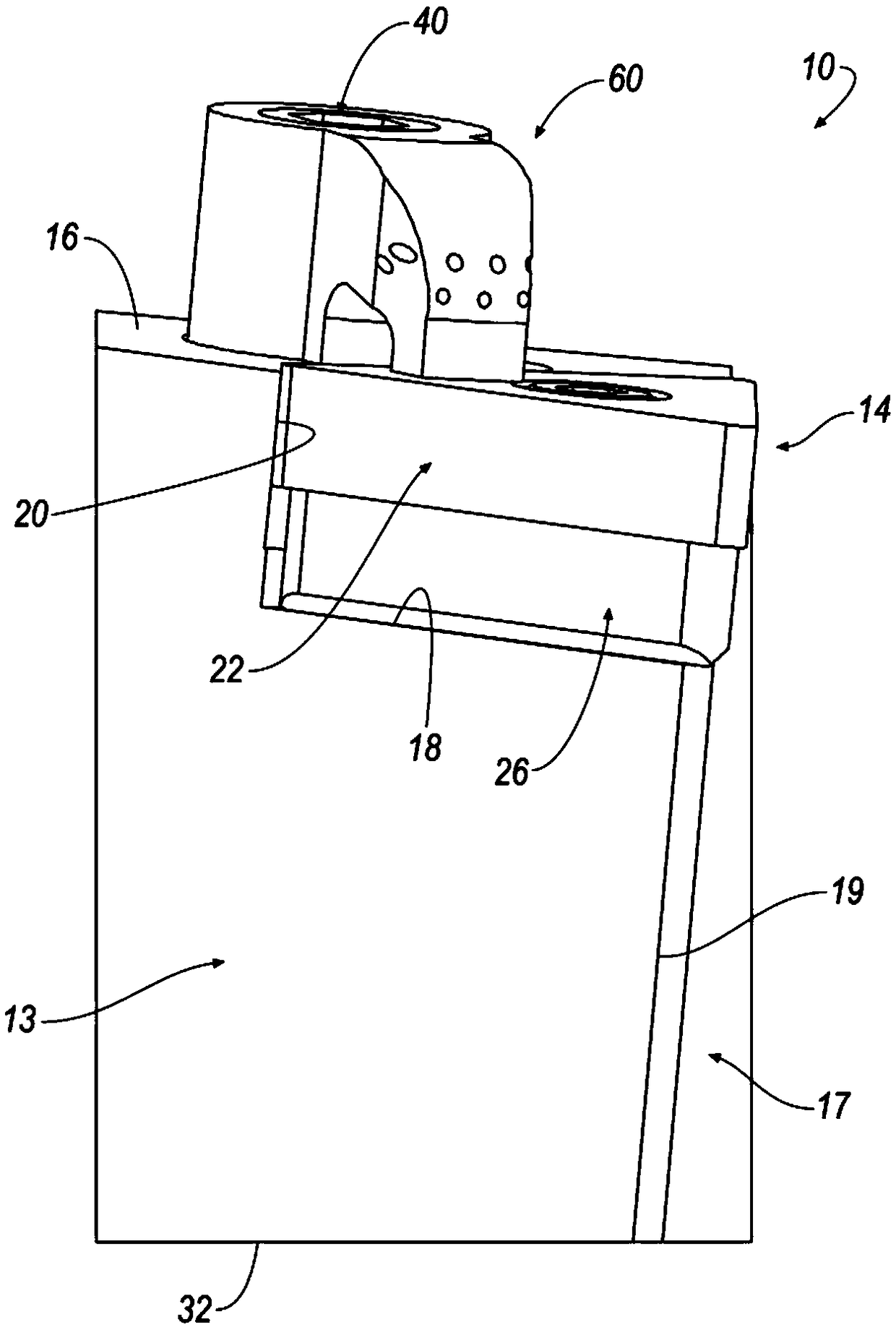

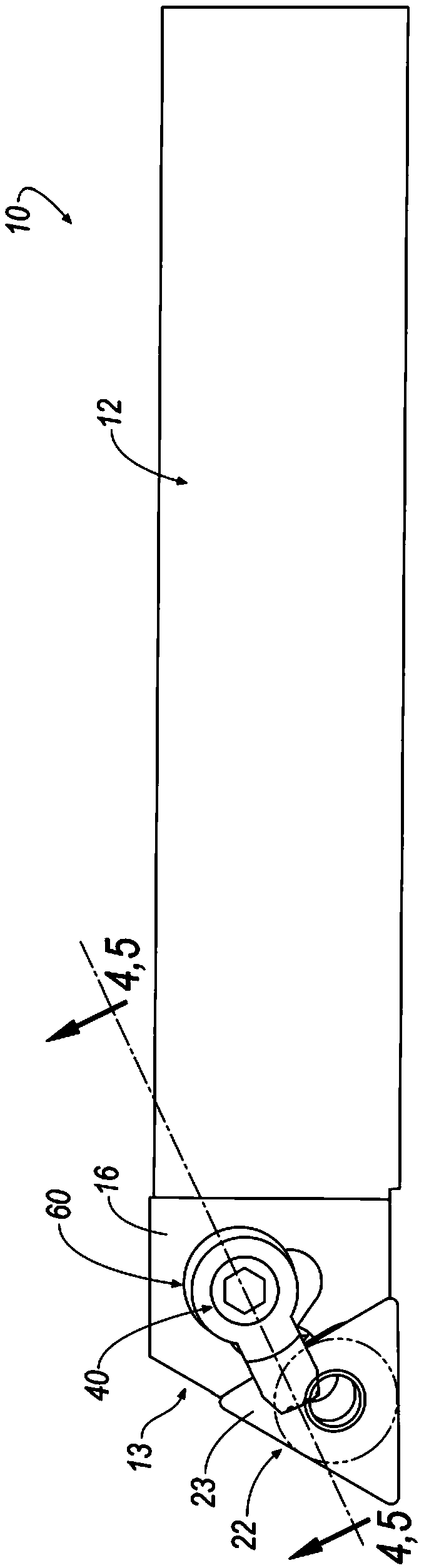

[0025] see now Figures 1 to 5 , shows a tool holder 10 according to an embodiment of the present invention. The tool holder 10 includes a body 12 having a head portion 13 with an insert receiving recess 14 formed in an upper surface 16 thereof at a corner 19 of a front end 17 thereof. The insert receiving pocket 14 has a bottom 18 and a rear support wall 20 .

[0026] In the illustrated embodiment, cutting insert 22 has a top surface 23 and a generally triangular shape. However, it should be understood that the cutting insert may have any polygonal shape, such as a rhombus, rectangle, pentagon, and the like. An optional seat member 26 may be disposed between cutting insert 22 and bottom 18 of pocket 14 to support cutting insert 22 when installed in pocket 14 . The seat member 26 may be securely secured to the insert receiving pocket 14 by threaded fasteners (not shown), such as screws or the like. In an alternative embodiment, the insert 22 may be disposed on the bottom 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com