Intelligent real-time acquisition and analysis system for vibration data of equipment bearing

A technology of bearing vibration and real-time acquisition, applied in mechanical bearing testing, measuring devices, instruments, etc., can solve problems such as property loss and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in conjunction with the following examples.

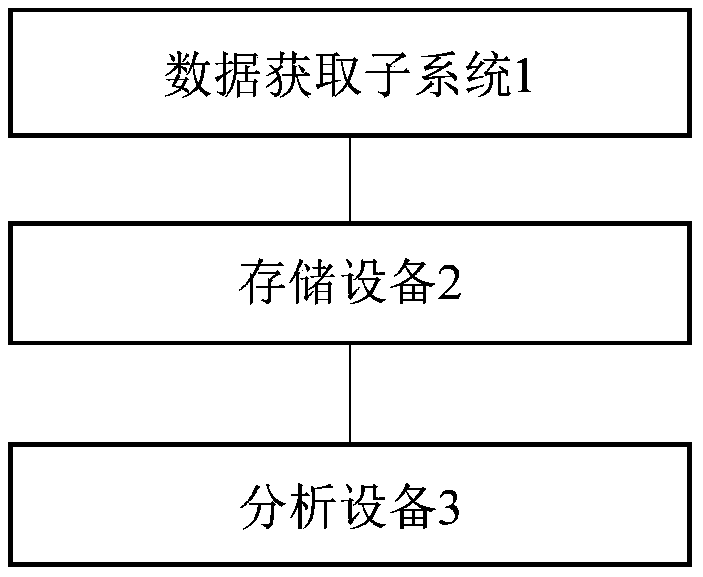

[0017] figure 1 A structural block diagram of an intelligent real-time acquisition and analysis system for equipment bearing vibration data according to an exemplary embodiment of the present invention is shown.

[0018] Such as figure 1 As shown, the embodiment of the present invention provides an intelligent real-time acquisition and analysis system for equipment bearing vibration data, the system includes a data acquisition subsystem 1 for collecting bearing vibration data, a storage device 2 for storing bearing vibration data, and a storage device for analyzing and an analysis device 3 for displaying the vibration data of the bearing; the data acquisition subsystem 1 and the analysis device 3 are both connected to the storage device 2 .

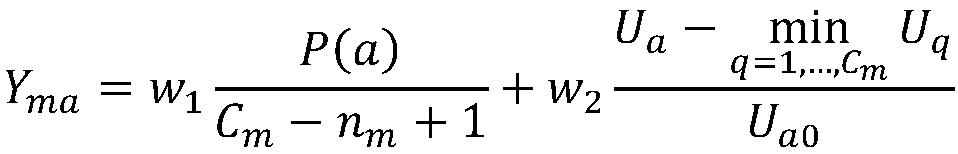

[0019] Wherein, the analysis device 3 analyzes the bearing vibration data in the storage device 2, including: preprocessing the bearing vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com