Method, device and system for identifying cavity capacity through vibration measurement

A vibration measurement and chamber technology, which is applied in the direction of measuring devices, measuring capacity, volume measuring instruments/methods, etc., can solve the problems of the chamber losing its transfer function, stalling, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

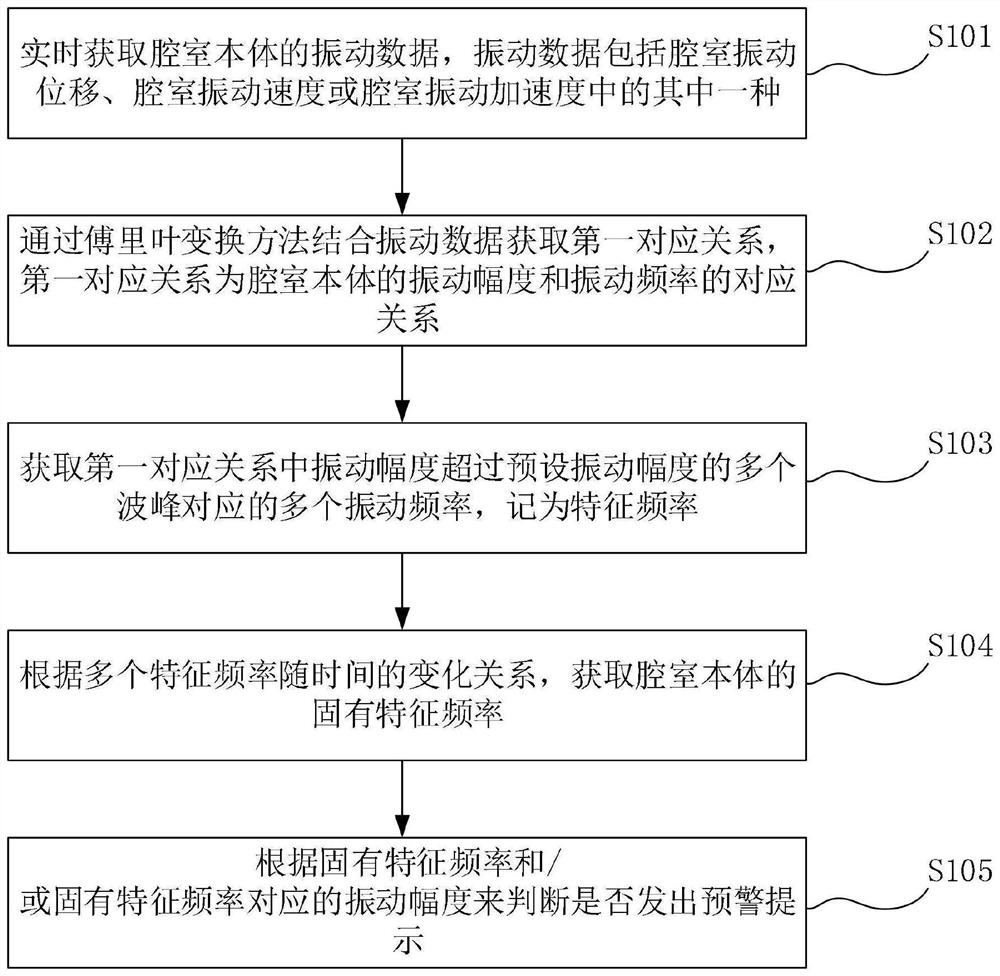

[0066] figure 1 It is a flow chart of the method for identifying chamber capacity through vibration measurement proposed by the embodiment of the first aspect of the present invention. Such as figure 1 As shown, the method for identifying chamber capacity through vibration measurement includes the following steps:

[0067] S101, acquiring vibration data of the chamber body in real time, the vibration data including one of chamber vibration displacement, chamber vibration velocity, or chamber vibration acceleration;

[0068] Wherein, the vibration data can be collected by a vibration sensor arranged on the chamber body. Vibration sensors are classified into one of displacement vibration sensors, velocity vibration sensors and acceleration vibration sensors.

[0069] If the vibration sensor is a displacement vibration sensor, the acquired vibration data of the chamber body is the vibration displacement data; if the vibration sensor is a velocity vibration sensor, the acquired...

Embodiment 2

[0106] Figure 5 It is a schematic block diagram of the device for identifying chamber capacity through vibration measurement proposed by the embodiment of the second aspect of the present invention. Such as Figure 5 As shown, the device 100 for identifying chamber capacity through vibration measurement includes:

[0107] A vibration data acquisition module 101, configured to acquire vibration data of the chamber body in real time, the vibration data including at least one of the vibration displacement of the chamber, the vibration velocity of the chamber, or the vibration acceleration of the chamber;

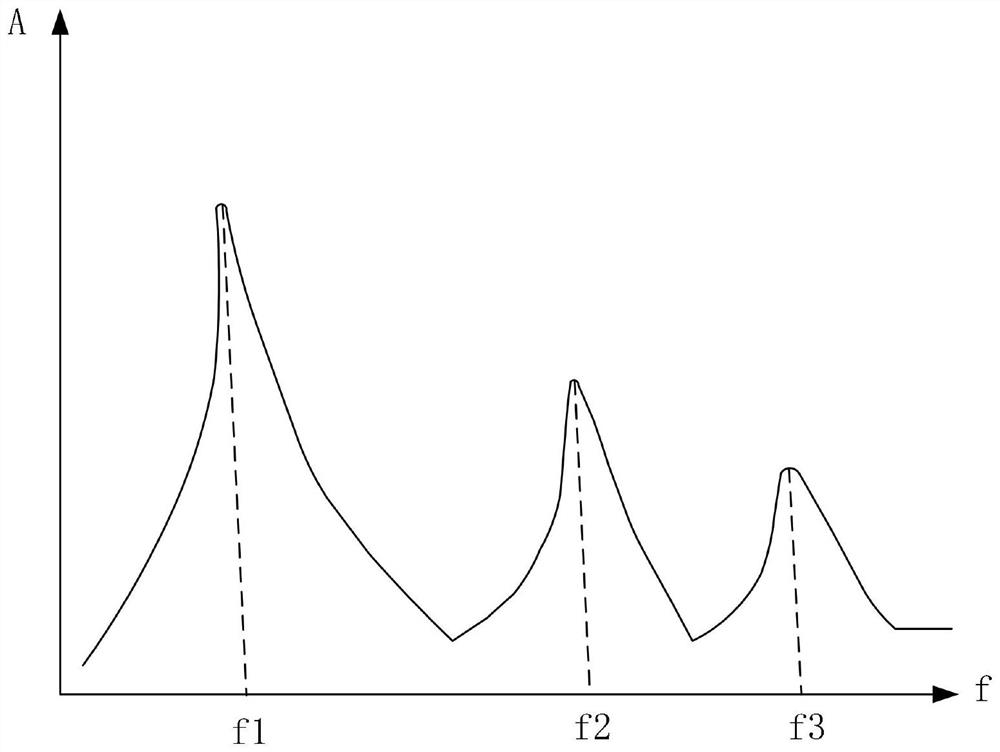

[0108] The first corresponding relationship acquisition module 102 is used to obtain the first corresponding relationship by combining the vibration data with the Fourier transform method, and the first corresponding relationship is the corresponding relationship between the vibration amplitude and the vibration frequency of the chamber body;

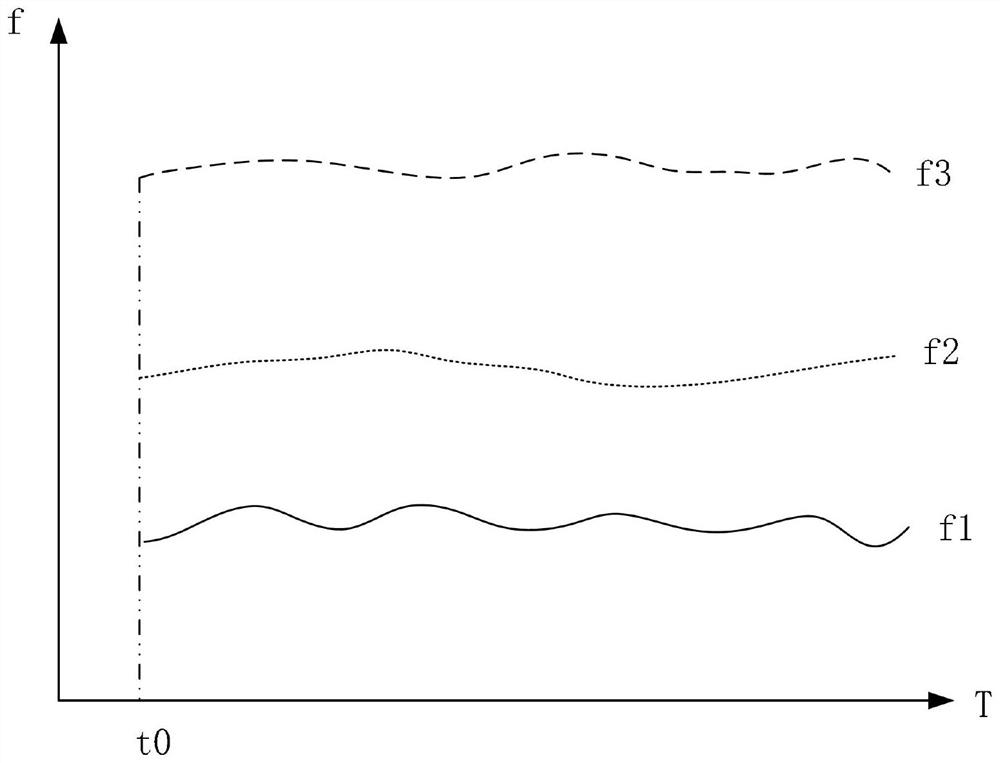

[0109] The characteristic freq...

Embodiment 3

[0130] Figure 6 It is a schematic structural diagram of a system for identifying chamber capacity through vibration measurement according to the embodiment of the third aspect of the present invention. Such as Figure 6 As shown, the system 200 for identifying chamber capacity through vibration measurement includes:

[0131] At least one vibration sensor 201 is fixed on the outer wall of the chamber body 203 through a fixed base 202;

[0132] Data acquisition card 204, one end is connected with vibration sensor 201, the other end is connected with processor 205, and another end is connected with power supply 206; The other end of vibration sensor 201 is connected with power supply 206;

[0133] The power supply 206 is used to supply power to the vibration sensor 201, the data acquisition card 204 is used to collect the vibration data of the chamber body 203 obtained by the vibration sensor 201, and the processor 205 is used to execute the method for identifying the chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com