Intelligent monitoring system for machine bearing vibration

A bearing vibration, intelligent monitoring technology, applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as property loss and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in conjunction with the following examples.

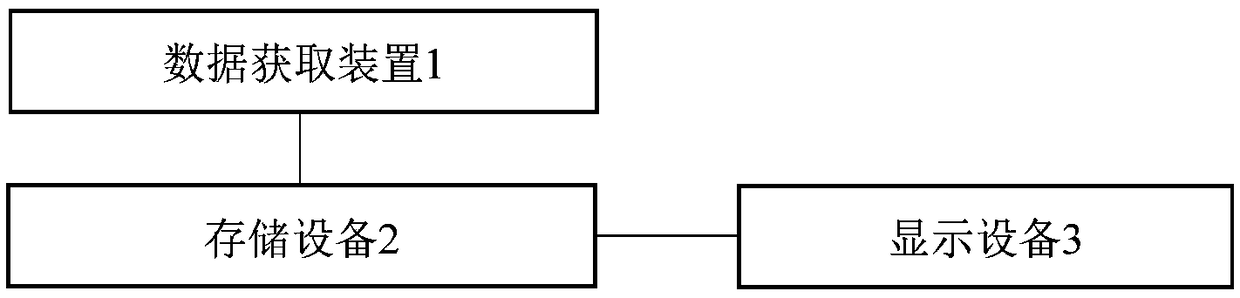

[0016] see figure 1 , the embodiment of the present invention provides a machine bearing vibration intelligent monitoring system, the system includes a data acquisition device 1 configured to collect machine bearing vibration data, a storage device 2 configured to store machine bearing vibration data and configured to display the A display device 3 for machine bearing vibration data; both the data acquisition device 1 and the display device 3 are connected to the storage device 2 .

[0017] In an optional manner, the display device is further configured to: before displaying the vibration data of the machine bearing, perform preprocessing on the vibration data of the machine bearing, including removing data abnormal points and data normalization .

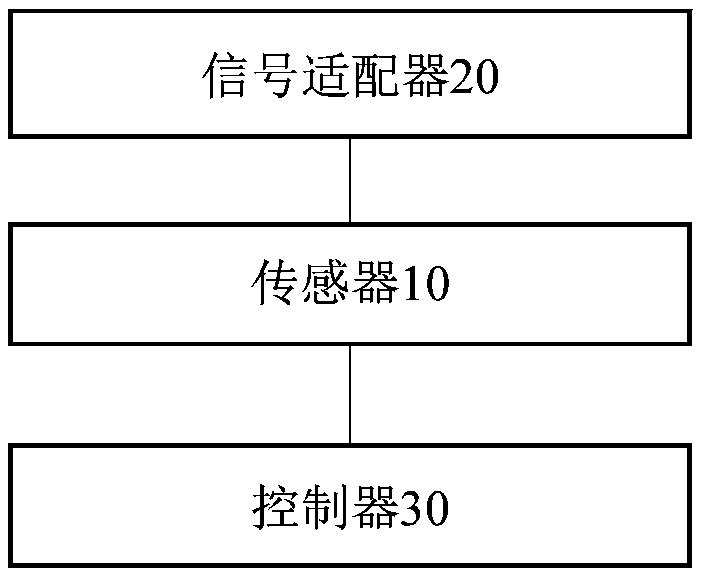

[0018] In a manner that can be implemented, the data acquisition device 1 includes a converging node and a plurality of sensor nodes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com