Camera mounting rack

A camera and mounting bracket technology, applied in the field of cameras, can solve the problems of providing support for rotation, difficult to meet installation requirements, and unable to adjust the camera at multiple angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

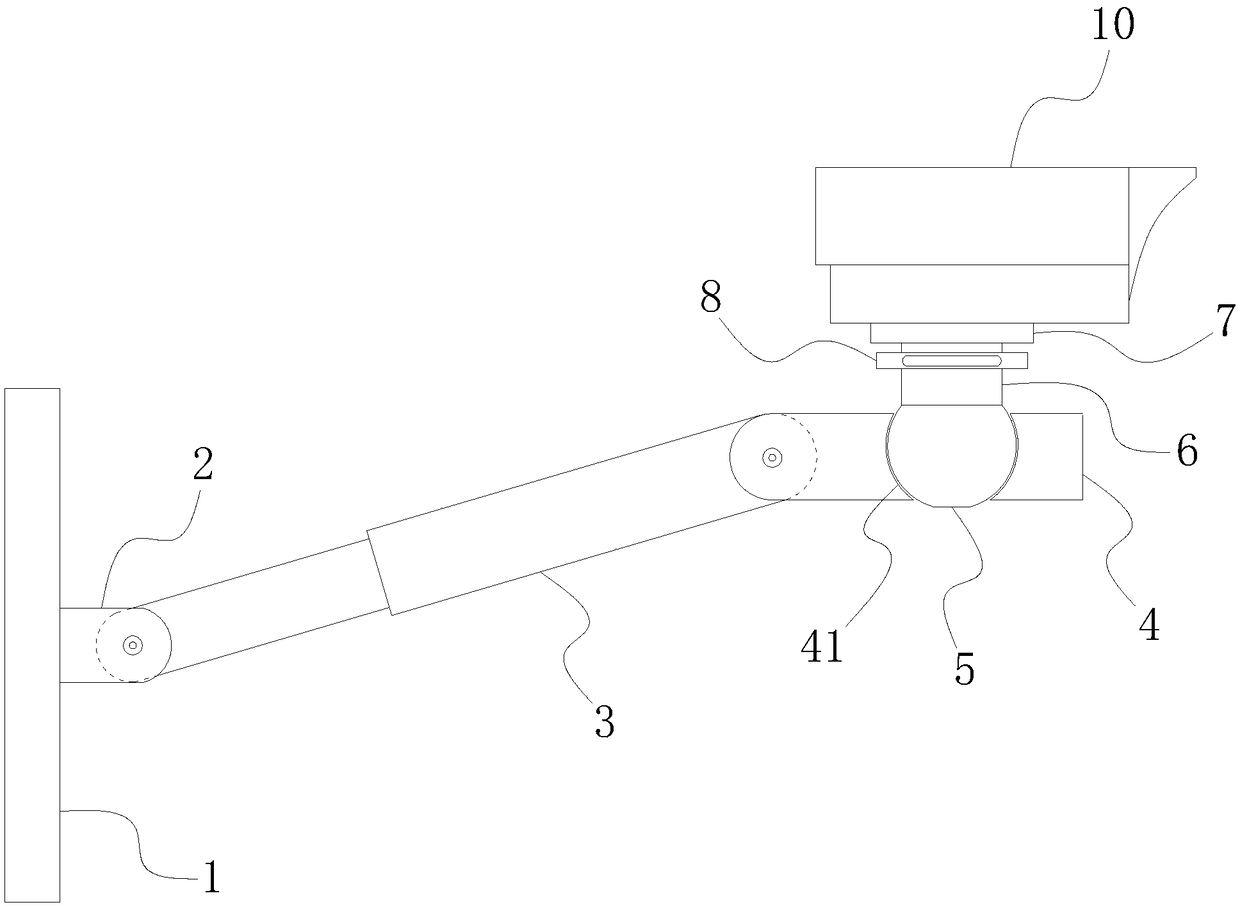

[0022] like Figure 1-Figure 4 As shown, a camera mounting bracket provided by the present invention includes the following components:

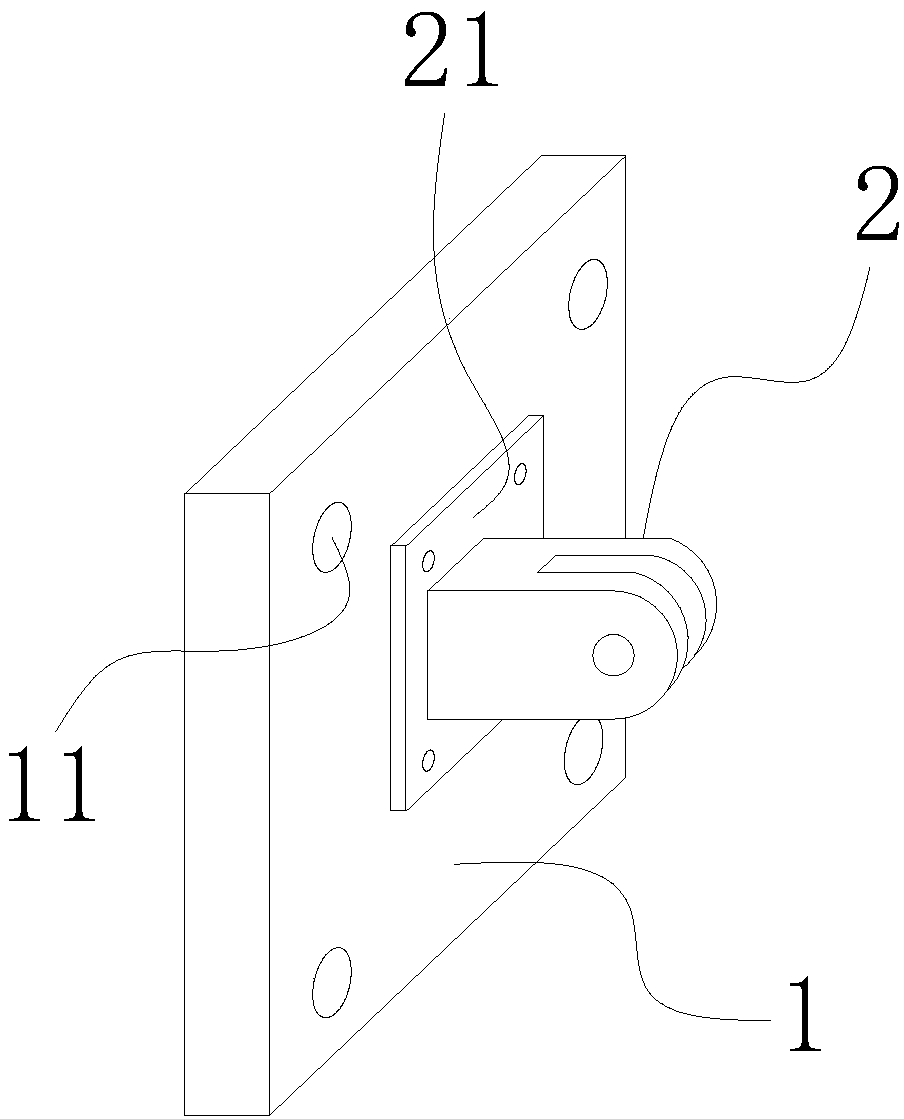

[0023] The fixed plate 1 is used for fixing to the wall, and the front of the fixed plate 1 is fixed with a connection ear seat 2;

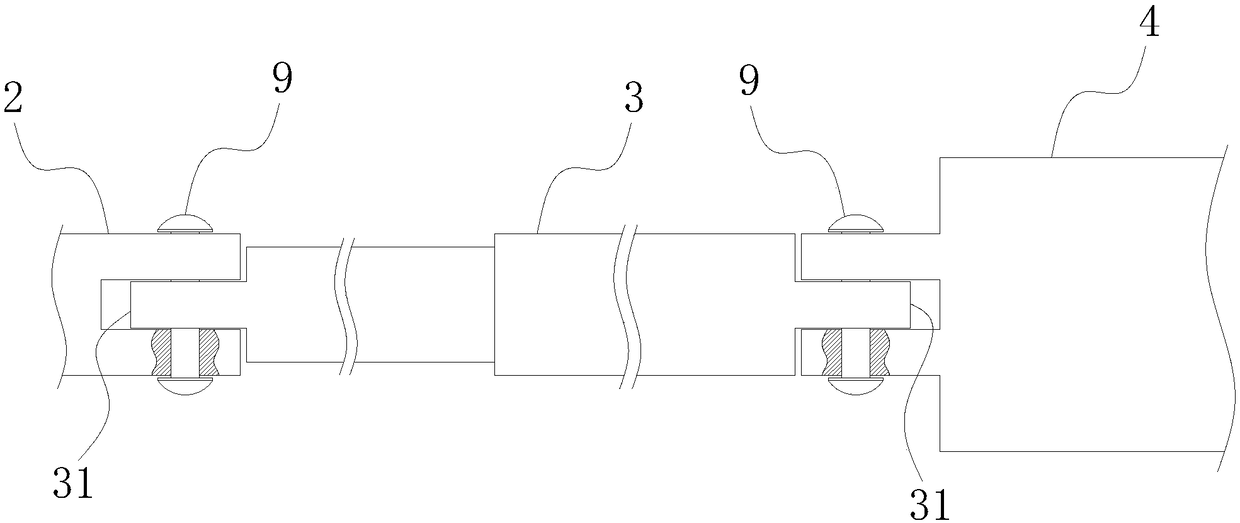

[0024] The telescopic rod 3 is rotatably connected to the connecting ear seat 2 at one end;

[0025] Support table 4, one end is rotatably connected with the end of the telescopic rod 3 away from the fixed plate 1; the inside of the support table 4 is provided with a mounting groove 41 whose wall surface is a spherical surface; preferably, as Figure 4 As shown, the support table 4 includes a front half 42 and a rear half 43, and the installation groove 41 is formed after the front half 42 and the rear half 42 are put together, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com