Large-torque actuator loading testboard

An actuator and high-torque technology, applied in the field of high-torque actuator loading test bench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

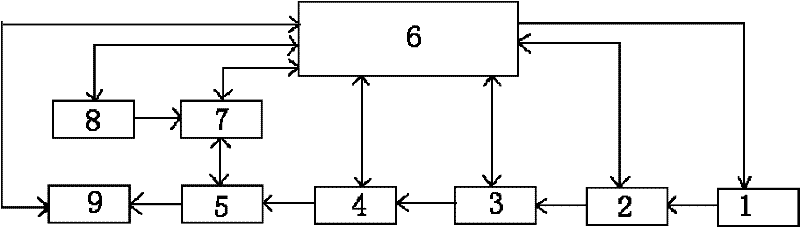

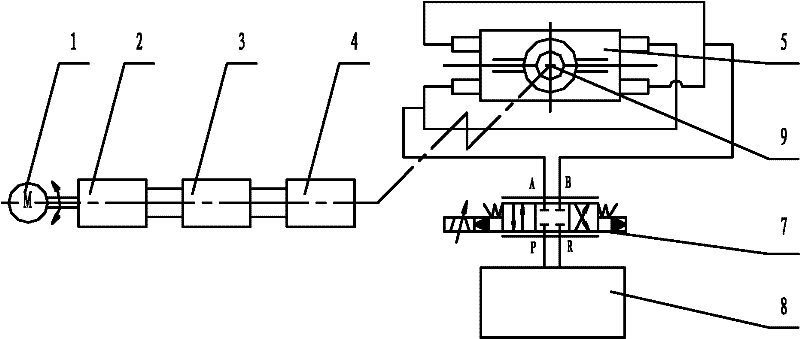

[0015] Referring to the accompanying drawings, it can be seen that the load test bench for a large torque actuator of the present invention includes a test piece 3, and it also includes a servo motor 1, an input torque sensor 2, an output torque sensor 4, a swing cylinder 5, a servo valve 7, and a hydraulic pump 8. The test piece 3 is located between the input torque sensor 2 and the output torque sensor 4, the servo motor 1 is connected to the input torque sensor 2, the output torque sensor 4 is connected to the swing cylinder 5, and the servo valve 7 is located between the swing cylinder 5 and Between the hydraulic pumps 8 , the oil at the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com