Test method for coal deformation under seam water injection fracturing influence and mining action

A technology of coal seam water injection and deformation test, which is used in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc.

Active Publication Date: 2019-01-04

SHANDONG UNIV OF SCI & TECH

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, domestic and foreign scholars focus on the field of coal deformation under the influence of coal seam water injection and fracturing, and there are few laboratory tests and theoretical studies. There is still a lack of an effective test device a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

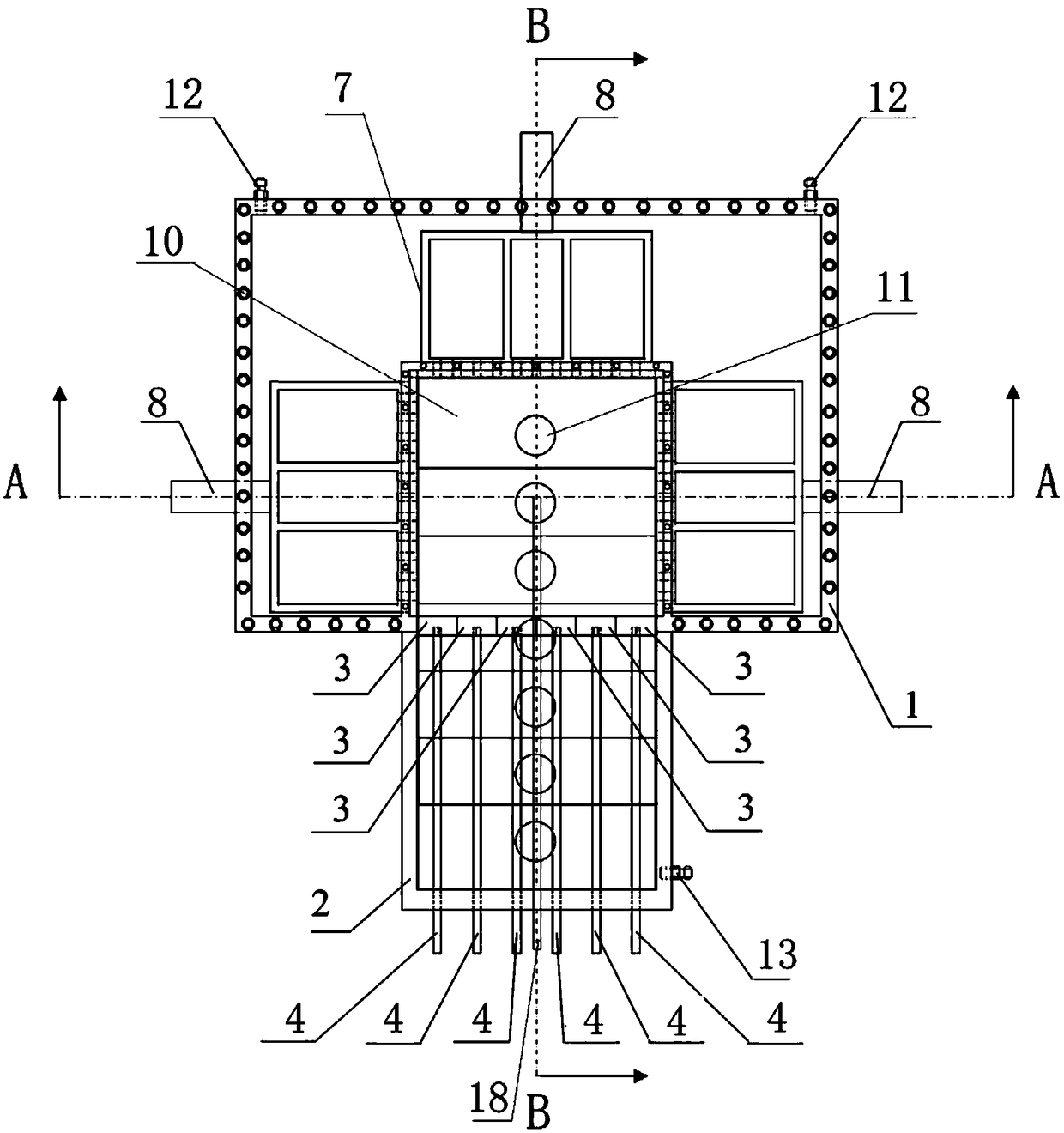

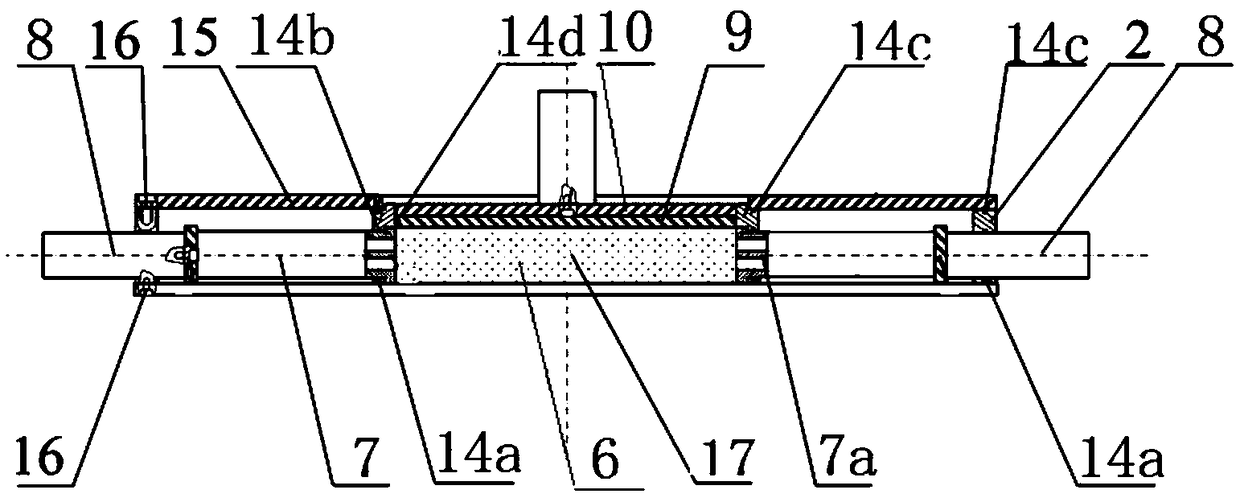

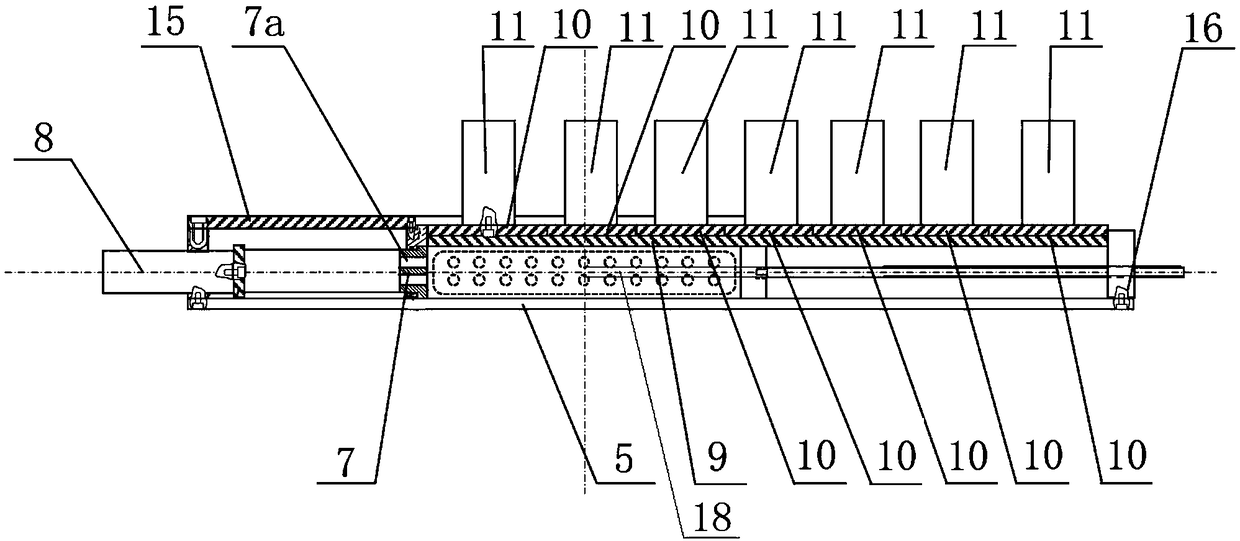

The invention discloses a test method for coal deformation under seam water injection fracturing influence and mining action. The test method includes the steps of manufacturing a test device that includes a sealed chamber in U shape and a transparent box, wherein a concave opening of the sealed chamber forms a test piece holding chamber, a front presser plate is provided with a front presser rod,the left, right and rear of the test piece holding chamber are provided with side presser plates, the front end of each side presser plate is provided with an air hole, each side presser plate is provided with a side presser rod, upper presser plates are arranged above an upper pad in front-rear adjacency manner, each upper presser plate is provided with an upper presser rod, and the end of eachupper presser rod is fitted with a spherical ball structure between two clamp plates; preparing coal powder; preparing a coal briquette test piece; mounting the coal briquette test piece and a fracturing pipe; applying triaxial stress; applying gas pressure; carrying out water injection fracturing; carrying out testing; carrying out other tests in the same group, and changing coal briquette test pieces with different permeabilities and strengths, and changing the water injection rate of the fracturing pipe; sorting test data. Therefore, triaxial true simulation test for coal deformation underseam water injection fracturing and mining actions.

Description

technical field [0001] The invention belongs to the technical field of coal mine safety and energy exploitation, and in particular relates to a coal body deformation test method under the influence of coal seam water injection and fracturing. Background technique [0002] Energy is the foundation and driving force of modernization, and energy supply and security are related to the overall situation of my country's modernization drive. In the national "Energy Development Strategic Action Plan (2014-2020)", it is pointed out that the production increase and clean and efficient utilization of conventional fossil fuels should be accelerated. In 2019, total coal consumption will be controlled at about 4.2 billion tons, shale gas production will strive to exceed 30 billion cubic meters, and coalbed methane production will strive to reach 30 billion cubic meters. [0003] In the development of conventional fossil fuels and unconventional oil and gas resources, in order to take int...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/02G01N3/08G01N3/12

CPCG01N3/02G01N3/08G01N3/12G01N2203/0019G01N2203/0044

Inventor 王刚刘义鑫程卫民孙路路

Owner SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com