Visualization test method for coal seam outburst caused by tunneling in working face

A test method, working face technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., to achieve the effect of optimizing the test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0031] A method for visualizing coal seam outburst caused by tunneling in a working face, comprising the following steps:

[0032] Step 1, making the test device.

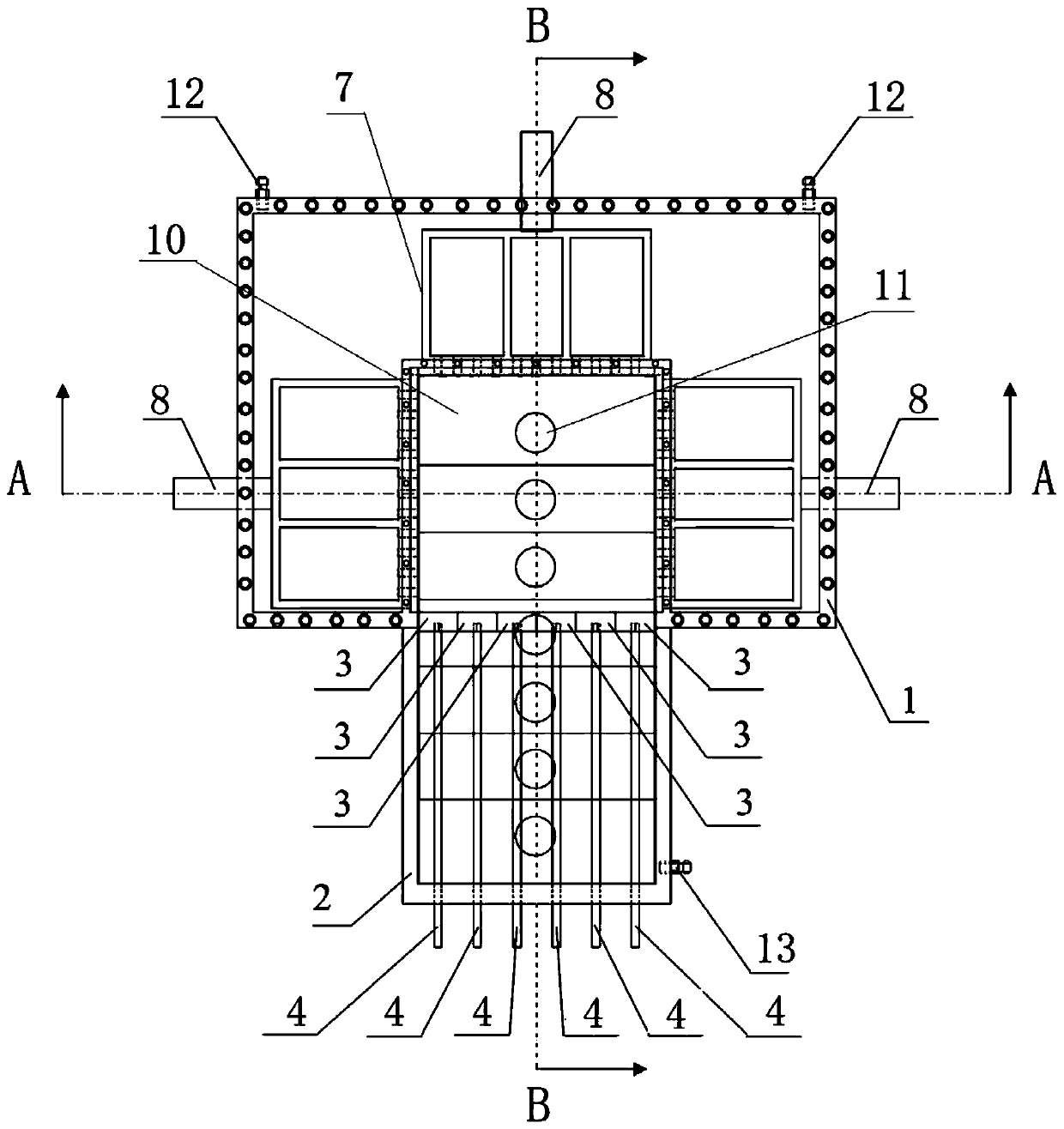

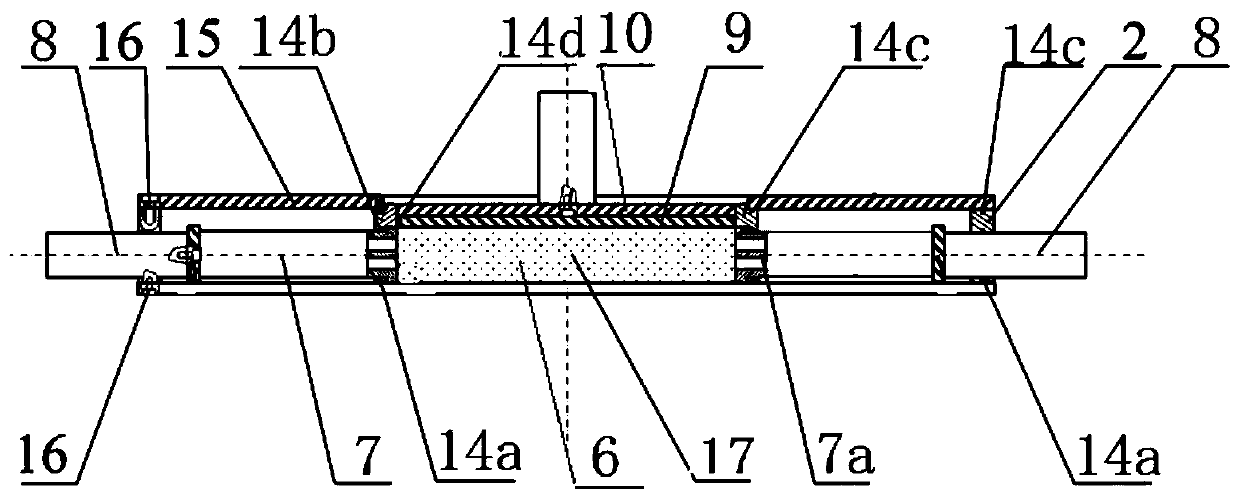

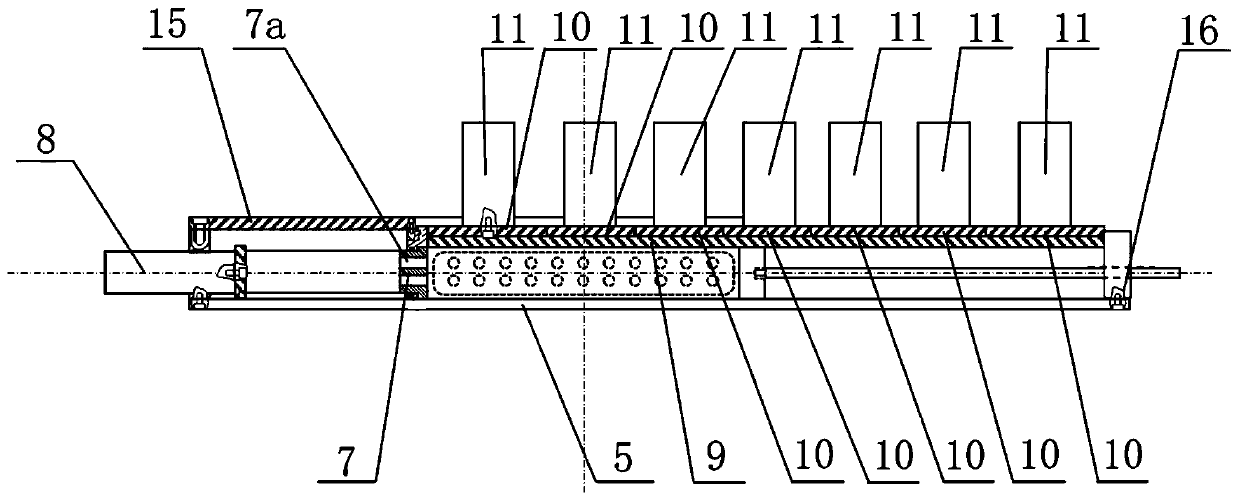

[0033] combine figure 1 — image 3 As shown, the test device is mainly composed of a sealed cavity 1, a transparent box 2, a front pressure plate 3, a front pressure rod 4, a side pressure plate 7, a side pressure rod 8, an upper backing plate 9, an upper pressure plate 10, and an upper pressure rod 11.

[0034] The sealed cavity 1 is in the shape of a "concave" as a whole, and the notch of the sealed cavity 1 faces forward.

[0035] A transparent box 2 with the same height and width as the notch is arranged in front of the sealed cavity 1 . The rear portion and the top of the transparent box 2 are open and just connected with the notch. The transparent box 2 and the sealed cavity 1 share...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com