A hemodialyzer and a production method thereof

A technology of hemodialysis and production method, applied in the field of medical devices, can solve the problems of undetectable dialysis membrane, undetectable sealing ring leakage, patient damage, etc., and achieve the effect of avoiding the risk of missing sealing ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

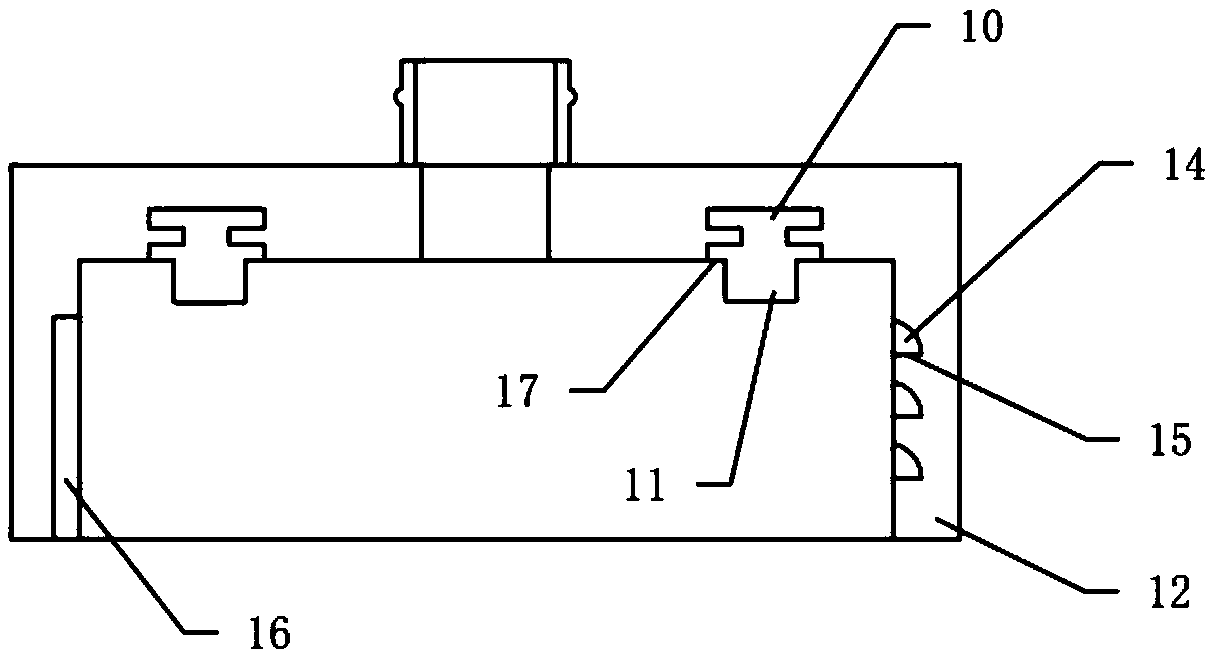

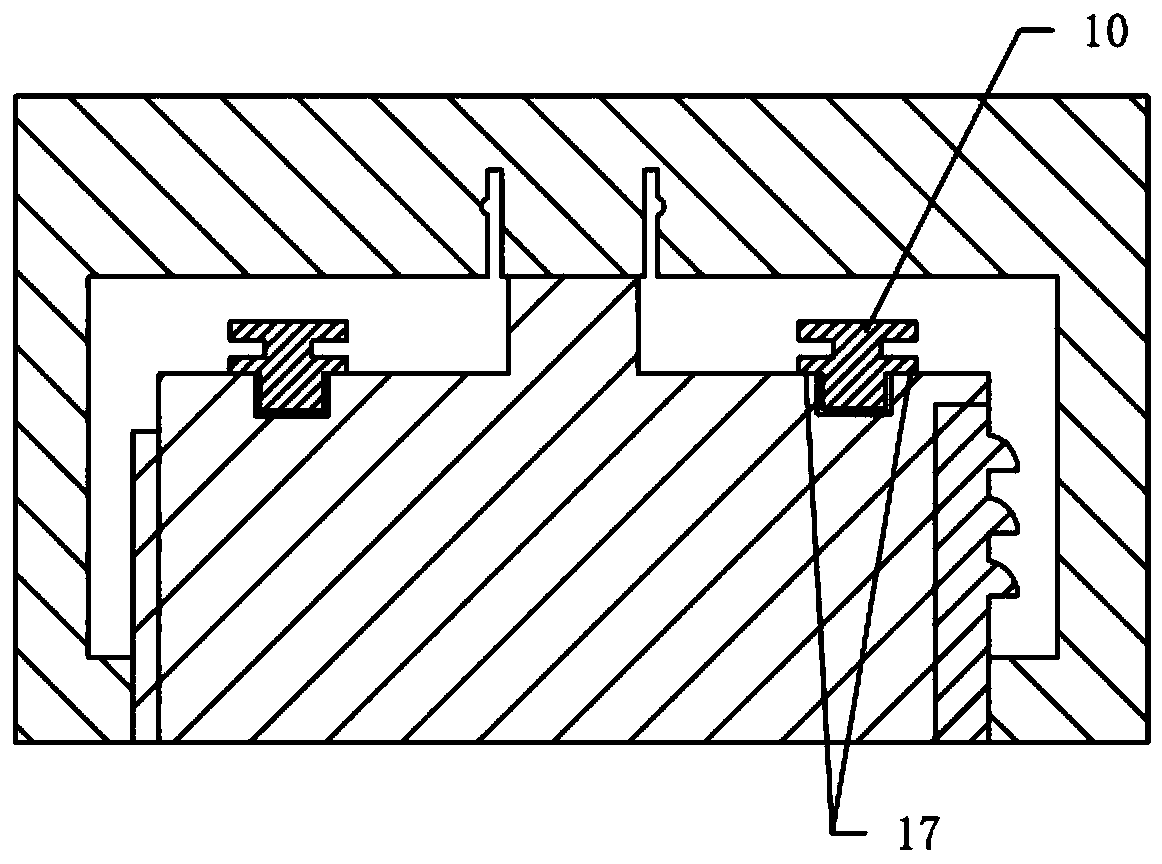

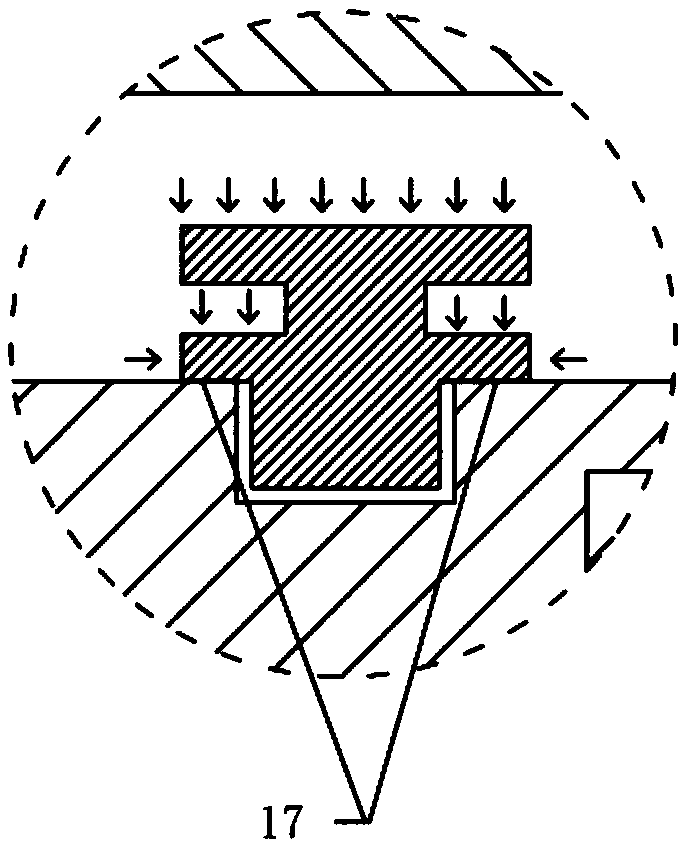

[0042] refer to Figure 1 to Figure 3 ,as well as Figure 7 to Figure 10 , which is Embodiment 1 of the present invention, specifically:

[0043]A hemodialyzer, comprising an end cover, the end cover includes a sealing ring and a cover body 12, a groove is arranged on the inner side of the cover body 12, the sealing ring includes a mounting part 10 and is connected with the mounting part 12. The sealing part 11 connected with the part 10, the mounting part 10 is set in the groove, the sealing part 11 protrudes out of the groove, and the sealing ring and the cover body 12 are in-molded and injected Integral molding, the installation part 10 is "I" type, the installation part 10 is provided with a connection plane 17, the sealing part 11 is connected with the connection plane 17, and the connection plane 17 is connected with the cover 12 are flush on the inner side.

[0044] In this embodiment, the groove is disposed on the top of the inner surface of the cover body 12 , and ...

Embodiment 2

[0065] refer to Figure 4 , Figure 5 , Figure 6 , which is the second embodiment of the present invention, specifically:

[0066] The difference from Embodiment 1 is that the groove is provided on the side wall of the inner surface of the cover body 12, the sealing part 11 is connected to the inner surface of the mounting part 10, and correspondingly, the connection plane 17 is also provided on the inner surface of the sealing part 11 . This embodiment is consistent with the effect achieved by the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com