Automobile interior decorating material air increasing compound device

A technology for automotive interior and composite equipment, which is applied in the field of aerated composite equipment for automotive interior materials, and can solve problems such as flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

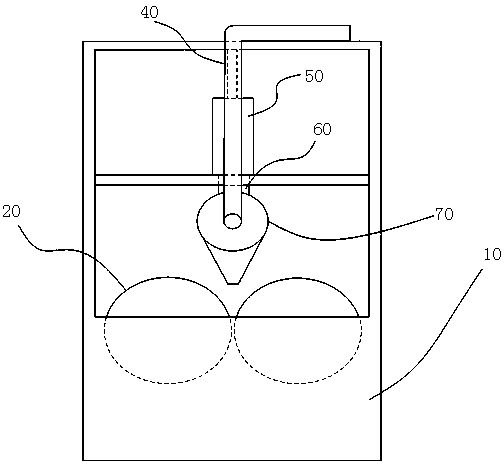

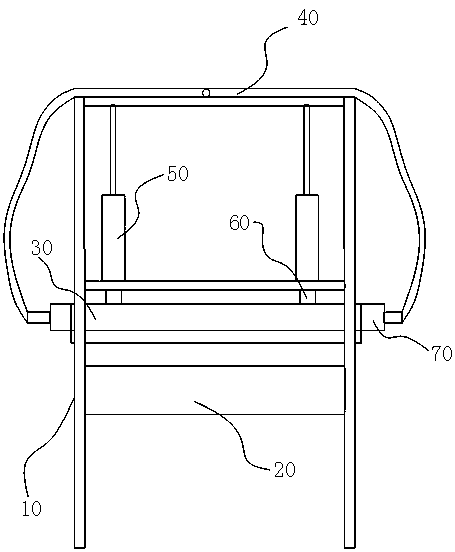

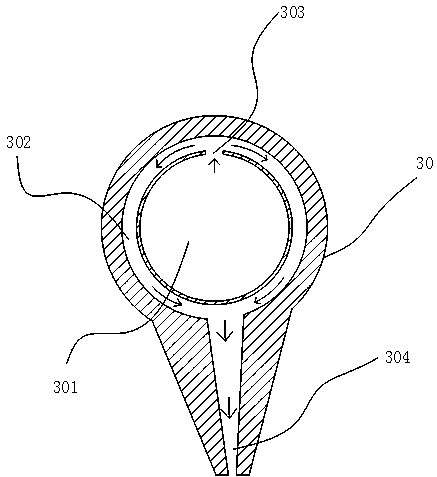

[0026] The invention relates to an air-increasing composite equipment for automobile interior materials, with roller devices and reels on both sides, which cooperate with them to realize the composite of PVC leather XPE materials. Rolled PVC leather and XPE materials are installed on the reel, and the front end is pulled out through the roller device and then sent to the air-increased compounding equipment, so that the PVC leather and XPE materials are bonded and compounded under the action of high-temperature gas.

[0027] The air-increasing composite equipment includes a frame 10, a pressure roller 20, and an air-heating mechanism. The pressure roller 20 is rotatably arranged on the frame 10 and rotates under the drive of the motor. The composite working station where PVC leather and XPE materials are compounded, the pressure roller 20 drives the displacement of PVC leather and XPE materials, and also realizes the pressing and bonding of PVC leather and XPE materials together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com