Prepreg stacking device and stacking method

A technology of prepregs and material racks, which is applied in the directions of transportation and packaging, object stacking, conveyors, etc. It can solve the problems of inconsistent stacking quantity of prepregs, time-consuming and labor-intensive manual stacking methods, and adverse effects on the quality of copper-clad laminates. Efficient material method, labor cost saving, and high stacking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

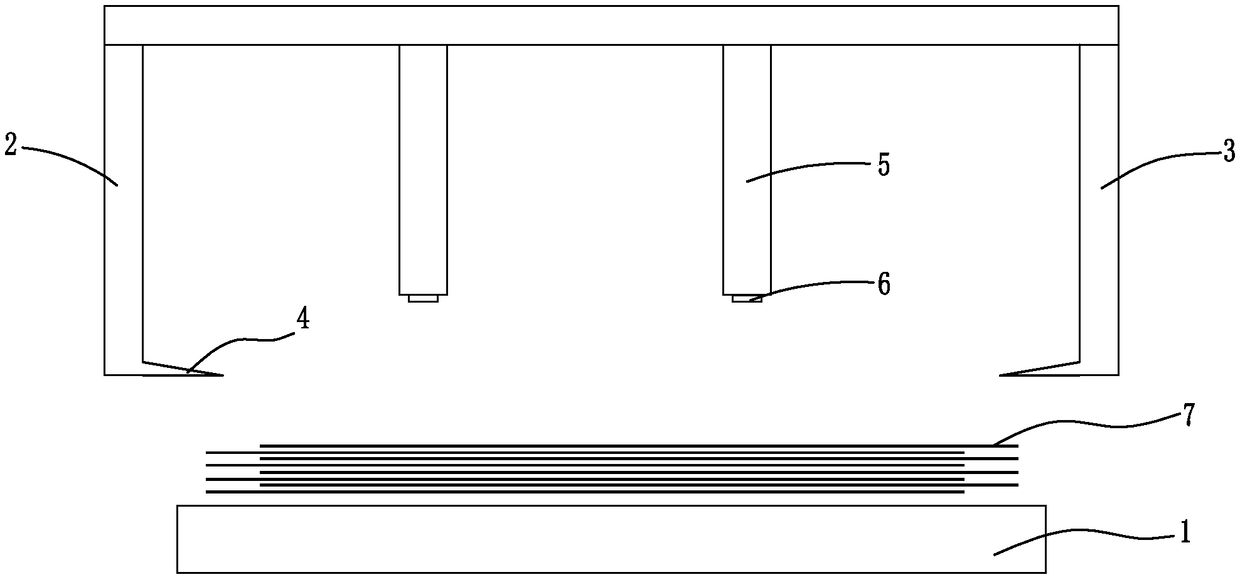

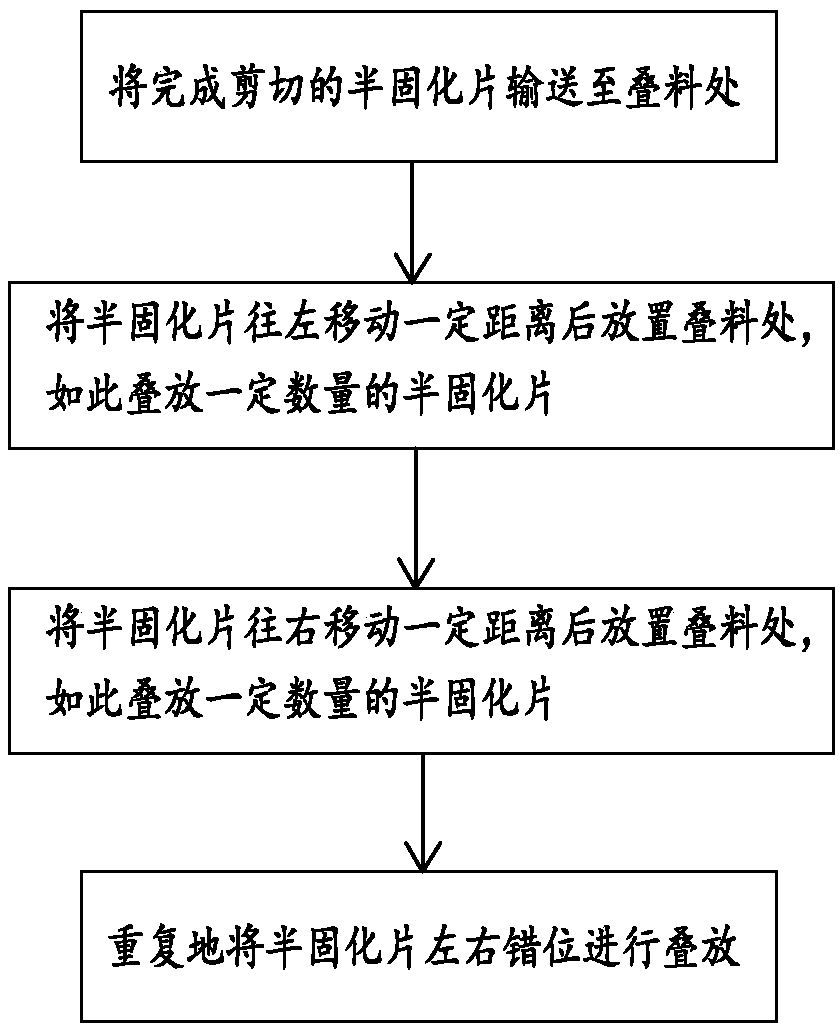

[0023] see figure 1 , an embodiment of the present invention provides a prepreg stacking device, including a frame, a conveyor belt, a stacking frame 1, a left mechanical arm 2 and a right mechanical arm 3 are arranged on the frame, wherein the conveyor belt is used to transport the prepreg 7 1. The stacking frame 1 is used to stack the prepreg 7. The left mechanical arm 2 and the right mechanical arm 3 are movable left and right on the frame and are located above the stacking frame 1, so that the left mechanical arm 2 and the right mechanical arm 3 Cooperating with each other, the prepreg 7 transported by the conveyor belt is stacked on the stacking frame 1 in a left-right misalignment manner, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com