Three-lock clamp locking mechanism with redundancy design

A technology of locking mechanism and buckle, which is applied in the direction of friction-clamped detachable fasteners, connecting components, mechanical equipment, etc., to achieve the effects of preventing axial deflection, easy operation, and reliable fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

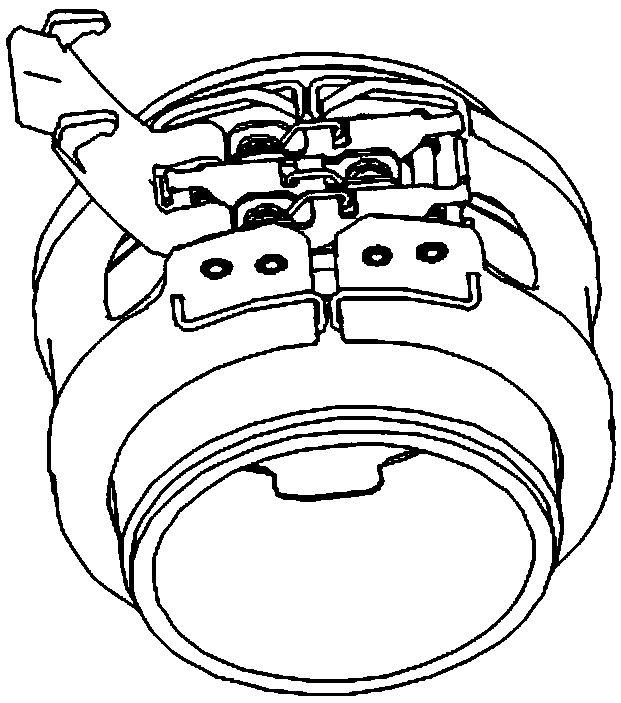

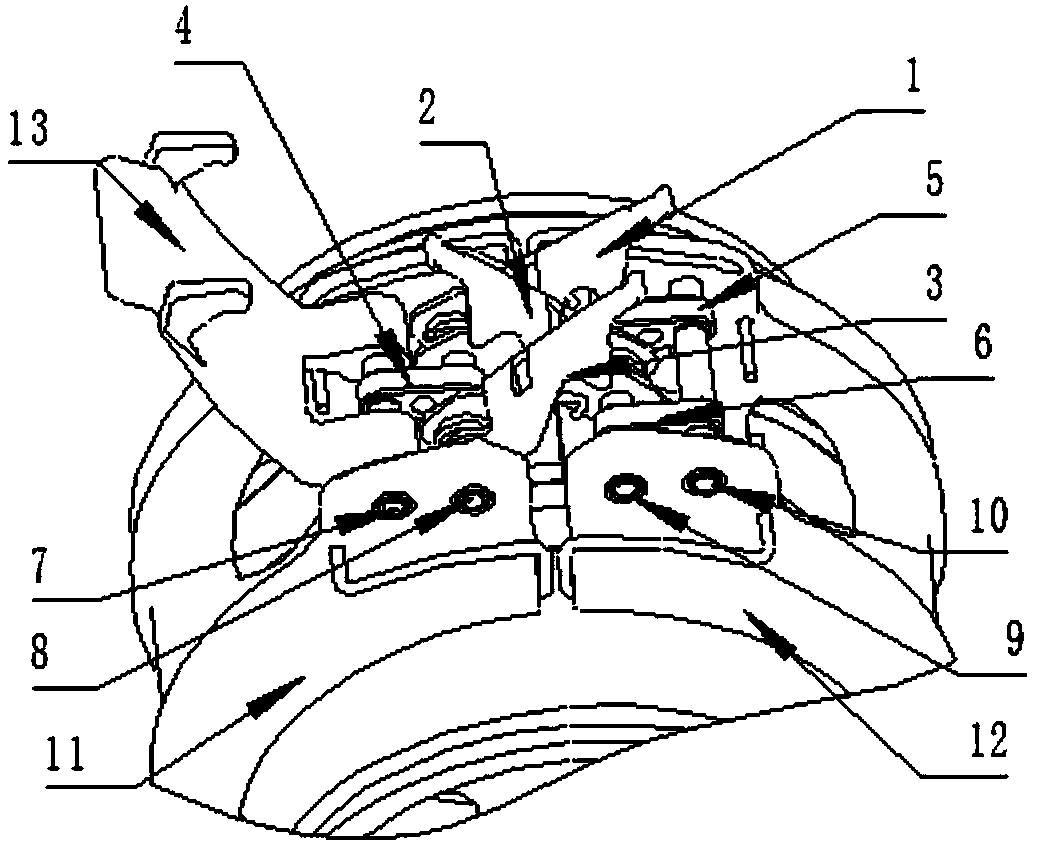

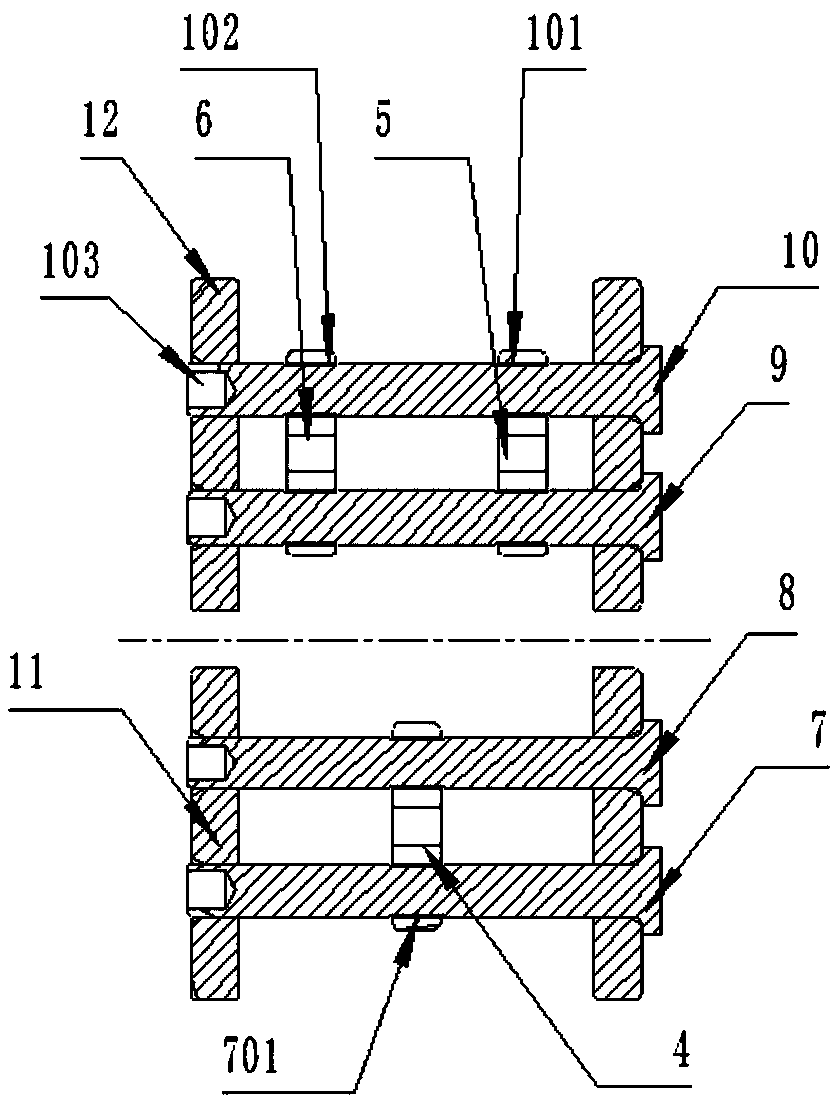

[0019] The three-dimensional schematic diagram of the three-lock clamp locking mechanism with redundant design of the present invention is as follows figure 1 As shown, the following combination figure 2 , image 3 , Figure 4 The specific embodiment will be described in detail.

[0020] The three-lock clip clamp locking mechanism with redundant design of the present invention, the overall structure is as follows figure 2 As shown, the clamp locking mechanism includes A lock 1, B lock 2, C lock 3, A connecting piece 4, B connecting piece 5, C connecting piece 6, A pin 7, B pin 8. C pin shaft 9, D pin shaft 10, first clamp housing 11 and second clamp housing 12; the relative positions of the A lock 1, B lock 2, and C lock 3 are triangular Distribution: A lock 1 is connected to B pin 8, B lock 2 is connected to C pin 9, C lock 3 is connected to B pin 8; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com